Great Planes Piper J-3 Cub 20 Kit - GPMA0158 User Manual

Page 4

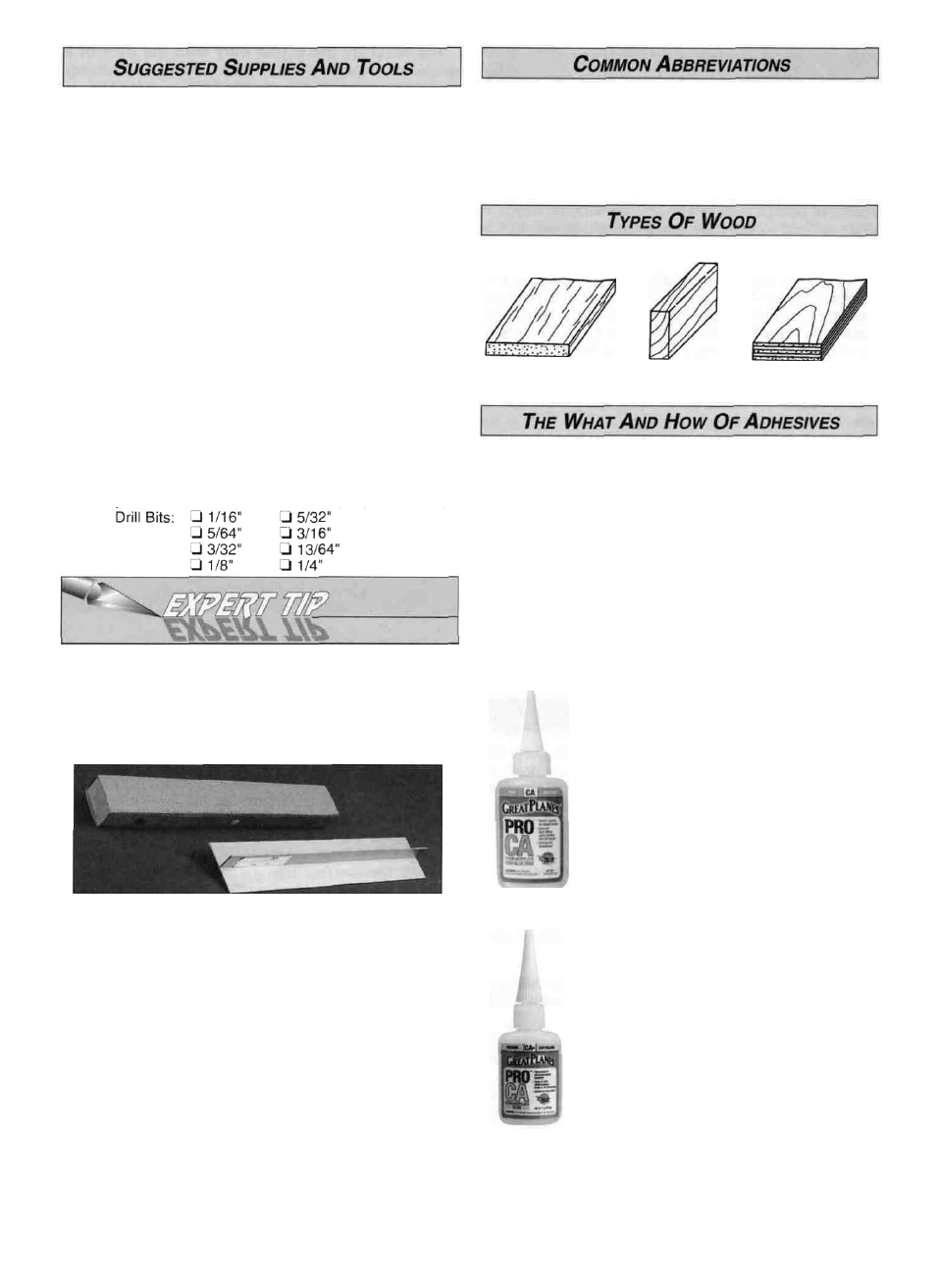

We recommend Great Planes Pro™ CA and Epoxy

D 2 oz Thin CA Adhesive - (GPMR6003)

D 2 oz Medium CA+ Adhesive - (GPMR6009)

D 1 oz. Thick CA- Adhesive - (GPMR6014)

D 6-Minute Epoxy - (GPMR6045)

D 30-Minute Epoxy - (GPMR6047)

D Pacer Formula 560 Canopy Glue

D Hand or Electric Drill

D Sealing Iron - (TOPR2100)

D Heat Gun - (TOPR2000)

D Hobby Saw - (X-acto® Razor Saw)

D Hobby Knife with #11 Blades

D Razor Plane - (Master Airscrew®)

D Screw Drivers - (Phillips and Slot tip)

D Flat File

D T-Pins Medium - (HCAR5150)

D String

D Straightedge with Scale

D Masking Tape - (required for construction)

D Sandpaper- (coarse, medium, fine grit)*

D T-Bar Sanding Block - (or similar)

D Lightweight Balsa Filler- (HCAR3401)

D #10-24 Tap and Tap Wrench

D IsopropyI Rubbing Alcohol - (70%)

D Dremel® Moto-Tool® or Similar - (optional)

D Kyosho® Curved Scissors (optional) - (KYOR1010)

*0n our workbench, we have four 11" T-Bar sanders,

equipped with #50, #80, #150 and #220-gnt sandpaper

This setup is all that is required for almost any sanding

task Custom sanding blocks can be made from balsa

for sanding hard to reach spots We also keep some

#320-grit wet-or-dry sandpaper handy for finish sanding

before covering.

T-Bar sanding tools are made from lightweight extruded

aluminum and can be found at most hobby shops A

2" x 11" strip of sandpaper is attached to the T-Bar by

gluing it on with rubber cement. Apply the rubber

cement to both the bottom of the T-Bar and the back of

the sandpaper When both surfaces are dry, press the

sandpaper firmly onto the T-Bar Spray adhesive can be

used for this purpose but it's harder to remove the

sandpaper when you need to replace it Wooden

sanding blocks can be made from straight 11" lengths

of 1" x 2" scrap lumber Start on one side, then wrap a

sheet of sandpaper completely around the wood,

ending on the same side as the one you started on.

Push 3 or 4 thumbtacks into this side, then trim off the

excess material.

Fuse = Fuselage

LG = Landing Gear

Stab = Stabilizer

" = Inches

Elev = Elevator

LE = Leading Edge (front)

Ply = Plywood

TE = Trailing Edge (rear)

Balsa Basswood Plywood

Cyanoacrylate: or CA glue has changed the way models

are built more than any other advance in modeling

technology In the good ol' days, model cement like

Ambroid, Duco, Comet and Sigment were the glues of

choice They all had a strong odor that could cause

dizziness, dried slowly (compared to CA) and became

brittle with age CA, on the other hand, is stronger, works

almost instantly and is bottled in three different viscosities

(thicknesses) CA is used for most glue joints, except where

epoxy is specified CA does emit rather strong fumes (some

say it's like tear gas) as it cures, so rule number one is to

work in a well ventilated area. All CA glues work best if the

joints are smooth and fit well.

Thin CA is also known simply as CA This

is the adhesive that has revolutionized

model building because it allows you to

assemble the parts first, then apply the

adhesive The thin formulation flows or

"wicks" into the joints and sets almost

instantly, eliminating the need to use pins to

hold things together while the glue dries.

You will often use thin CA for the initial

bond, but then follow with medium or thick

CA for extra strength, especially when

gluing plywood or hardwood.

CA+ is also known as medium or gap

filling CA CA+ is used for surface gluing,

filling small gaps between poorly matched

parts and for general purpose applications.

It cures slower than thin CA, allowing you to

apply a bead to two or three parts before

assembly Curing time without accelerator is

20 - 30 seconds.

4