Great Planes Piper J-3 Cub 20 Kit - GPMA0158 User Manual

Page 10

D 4 Trial fit but do not glue the tail gear wire in the rudder.

Make adjustments if necessary.

D 5 Temporarily pin the elevators on the plan Lay the

3/32" elevator joiner wire in place on the elevators and

mark its outline using a soft leaded pencil NOTE: Mark the

elevator joiner wire outline very lightly so that it can be

sanded off easily

D 10 Sand the leading edges of the stabilizer and fin and

the trailing edges of the elevator and rudder to a rounded

shape, as shown in the cross-section on the plan.

We have found that it's much simpler to do all hinging

after the model is covered.

D 1 Build one wing "half" or panel at a time You may want

to cut out each wing panel from the plan sheet to place on

your building board Tape the plan to your flat building

board and cover it with waxed paper Begin with the right

wing panel.

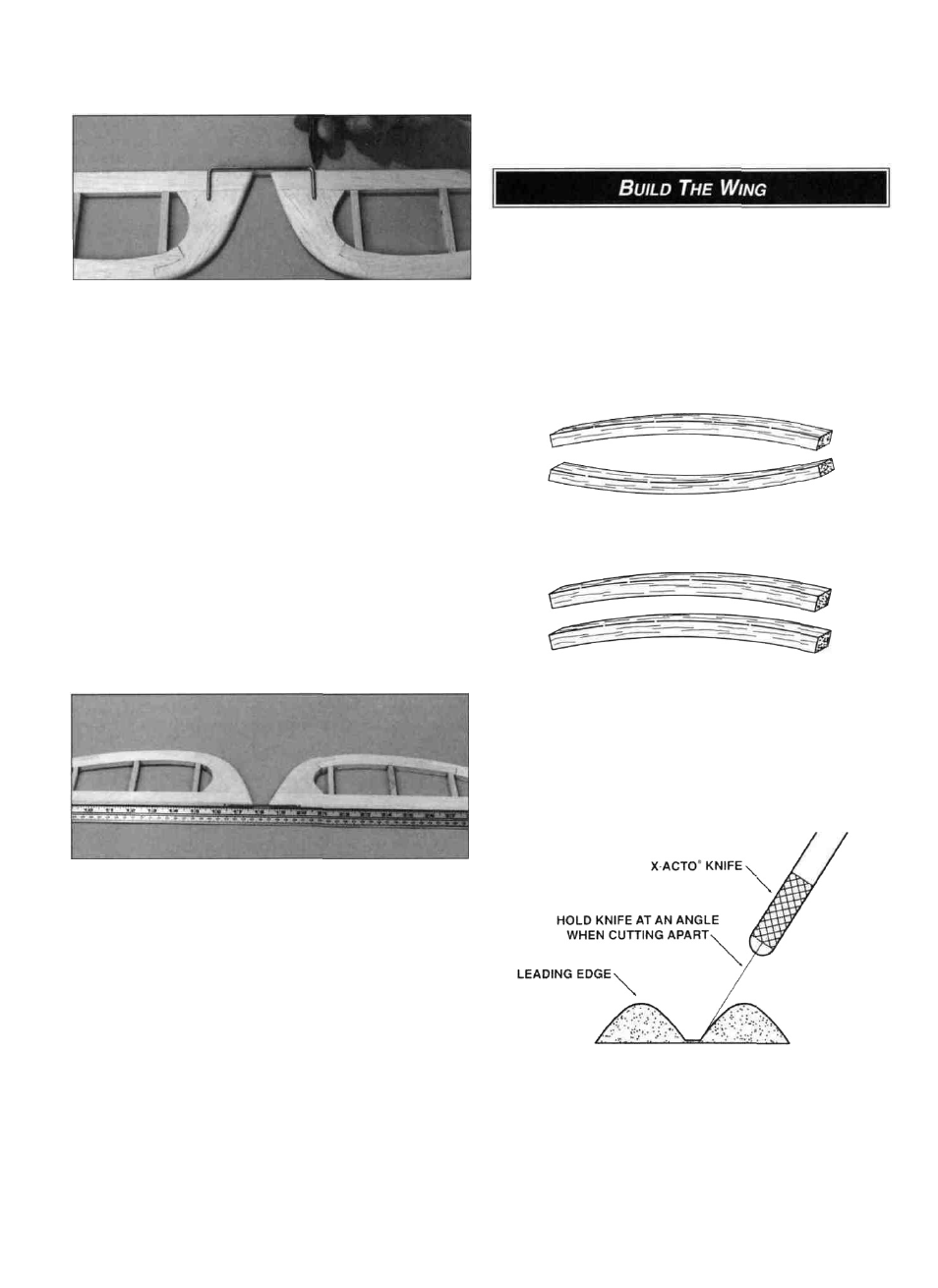

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

D 6 Accurately drill a 1/16" diameter pilot hole

approximately 3/4" deep and perpendicular (90°) to the LE,

at each location Then drill the final hole with a 7/64" drill bit

to a depth of 7/8" (The hole is drilled slightly oversize to

allow for positioning, and to allow room to create a hard

epoxy "sleeve" around the wire).

D 7 Use your sharpened 1/8" diameter brass tube to cut a

groove in the leading edge of both elevators to accept the

elevator joiner wire Slightly round the inside corner where

the groove meets the hole to allow for the bend in the

elevator joiner wire.

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

D 8. Test fit (do not glue yet) the joiner wire into both

elevators Position the elevators against a straightedge to

check for straightness of the LE with the joiner wire

installed If the leading edges don't match up with the

straightedge, you may slightly enlarge the holes drilled in

the elevator leading edges Make sure both elevators are

flat on the work surface If both elevators do not lie flat, you

can make slight adjustments by twisting the joiner wire.

D 2. Locate all four 1/4" x 5/16" x 27" balsa spars and

examine them carefully for possible imperfections Look for

knots, soft spots, diagonal grain and any other

imperfections If possible, position each spar so the

imperfections are on the outer half of the wing panel

(toward the tip), where they will be least affected by high

stress If the spars are warped slightly try to "balance them

out" by installing the warped spars in opposite directions

(see sketch above).

D 9. Carve or sand the bevel on the leading edges of the

elevator and rudder A razor plane allows you to rough-in

the bevel before finishing with a sanding block Refer to the

plan for the correct angle

D 3. The shaped and notched wing leading edges (LE)

and trailing edges (TE) are fastened together by thin strips

of balsa Separate them by cutting with a hobby knife, as

shown in the sketch above

10