Great Planes Piper J-3 Cub 20 Kit - GPMA0158 User Manual

Page 18

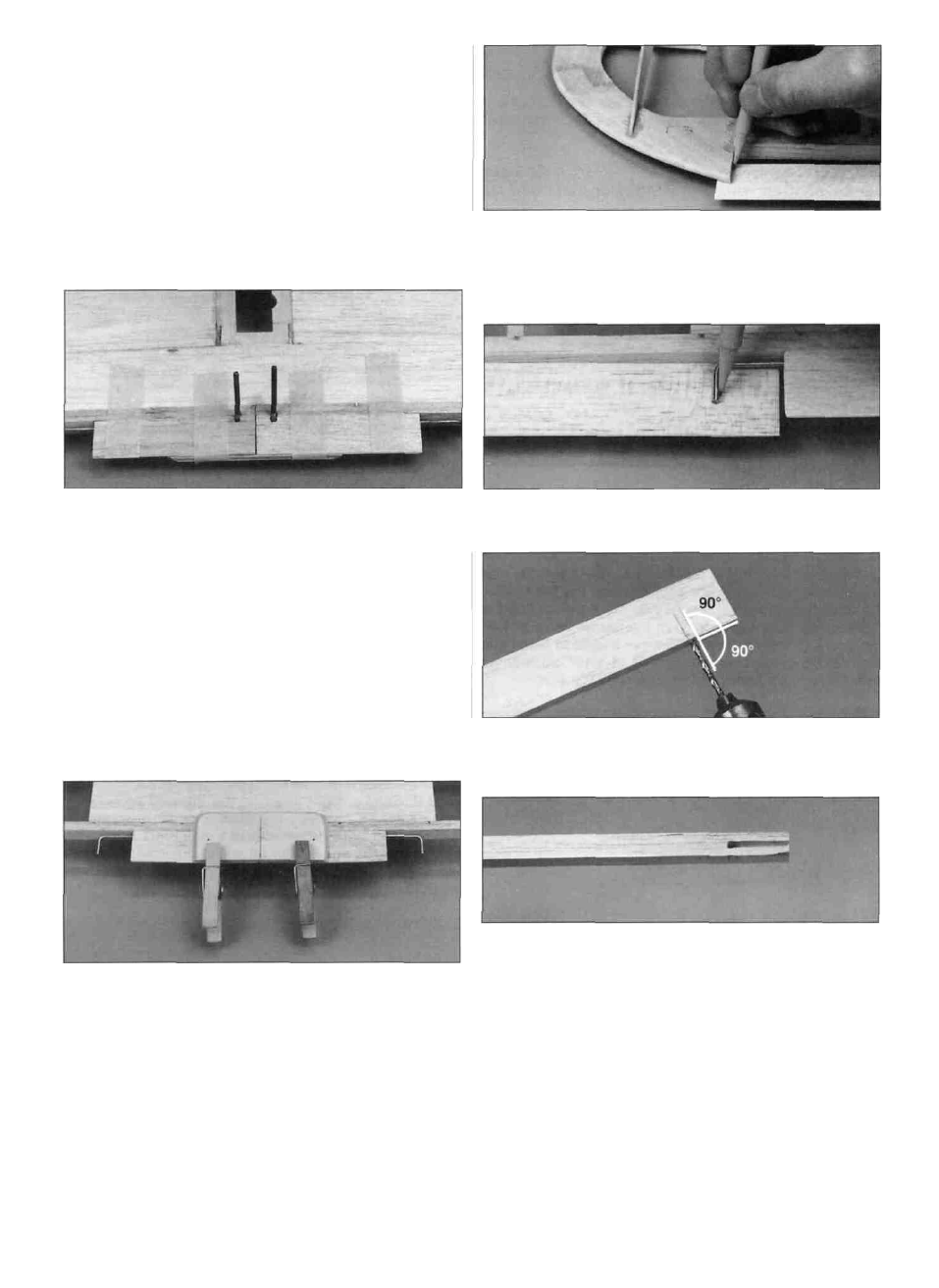

D D 4. To provide better glue adhesion, roughen the nylon

surface of both torque rod tubes with coarse sandpaper.

Clean the nylon tubes with alcohol and a paper towel.

D D 5. Lightly coat the torque rods with petroleum jelly,

then slide the nylon tube back and forth a few times to

lubricate the inside of the tube. This procedure will prevent

the torque rods from being glued to the tube during the

next step.

D D 8. While holding a 1-1/8" x 27" balsa aileron against

the inside edge of the wing center TE, draw a line on it that

matches the inside edge of the wing tip TE. Cut the

aileron 1/8" shorter than the TE opening to allow for

covering material.

D D 6. Coat the center section of the nylon bearings with

30-minute epoxy. Then insert the tubes into the grooves of

the wing center TE. Wipe off any epoxy that may squeeze

out with a paper towel. Apply epoxy to the forward edges of

the wing center TE (keep it out of the notches) then glue

them in position as shown on the plans. Use masking tape

to hold the wing center TE in position while the

epoxy cures.

Note: Allow the epoxy to harden completely before

proceeding with step 7.

D D 9. Hold the aileron in position, centered in the

opening, then mark the location of the torque rod arms.

D D 10. Draw a centerline on the forward edge of the

aileron. Drill a 7/64" hole, 3/4" deep, perpendicular to the

forward edge of the aileron to accept the torque rod arm.

D D 7. Draw a centerline on the die-cut 1/16" birch ply

wing plate. Sand a bevel on the front and sides of the

wing plate with 80-grit sandpaper. Leave the aft edge of the

wing plate square. Use 6-minute epoxy to glue the wing

plate in position on the top of the wing. Use the centerline

you drew to align the wing plate with the centerline of the

wing. The aft edge of the wing plate must be flush with the

aft edge of the wing center TE. Clamp the wing plate in

position while the epoxy cures.

D D 11. Cut a groove from the inboard edge of the aileron

to the hole to accept the torque rod. Hint: Use your

sharpened piece of 1/8" brass tubing for this task.

D D 12. Sand the forward edge of the aileron to a "V."

Refer to the cross-section of the wing on the plans for the

desired angle

Well, you are about halfway through the framing stage, so

clean up your workbench, have a soda and let's build

the fuse.

18