Great Planes Piper J-3 Cub 20 Kit - GPMA0158 User Manual

Page 23

D 5 Reinstall the LTF, TTF, cabin brace and the firewall

into the fuselage Practice clamping the fuselage sides

together around the firewall and tank floors, making sure

the firewall fits into its respective notches It may be

necessary to use hardwood sticks to evenly distribute the

force of the clamps on the fuselage sides Clamp the sticks

together with masking tape, lots of rubber bands or clamps

Once satisfied with the fit of all parts, glue them together

with 30-minute epoxy.

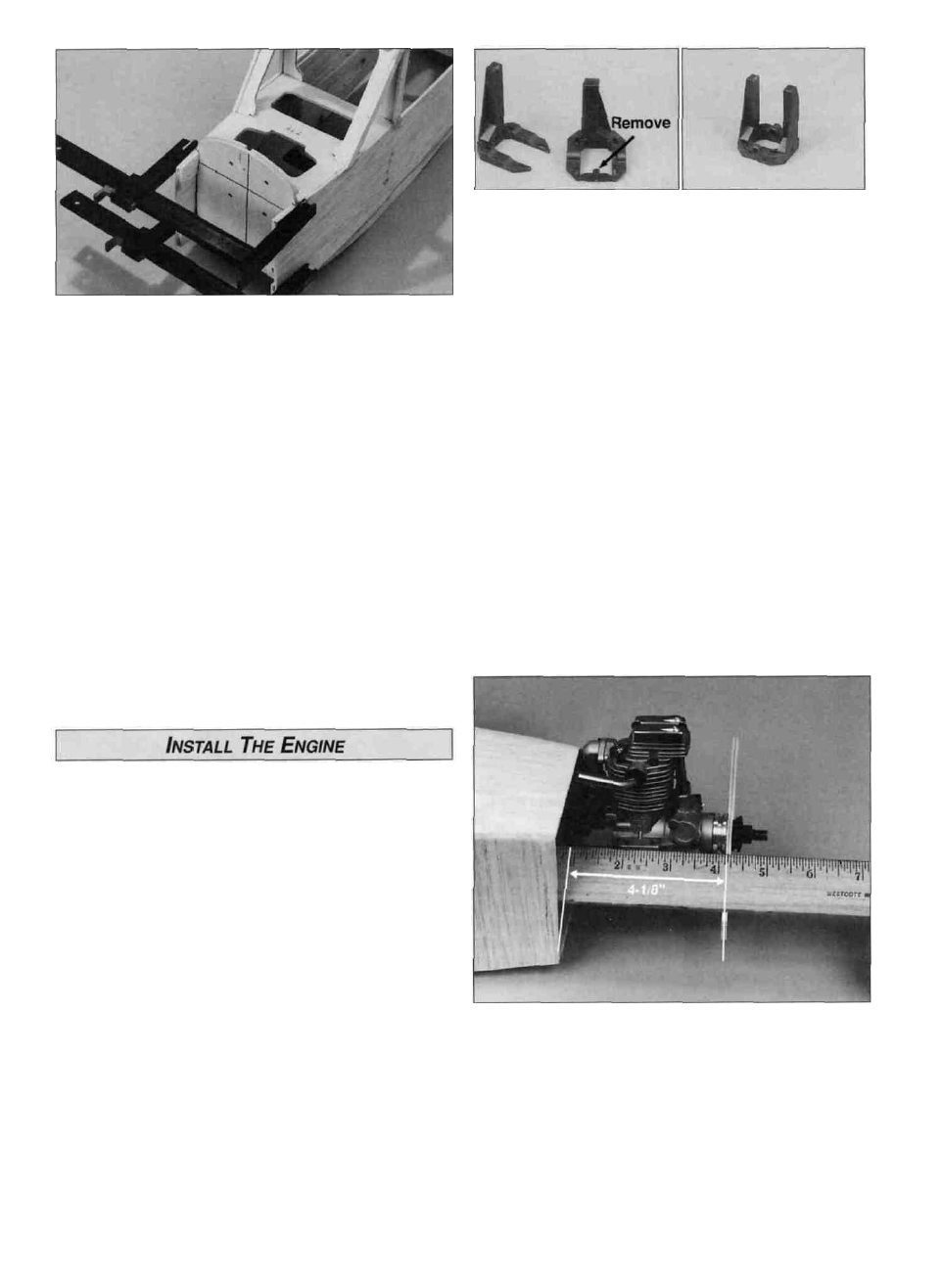

If you are using the included Great Planes adjustable

engine mount, cut or break the "spreader bar" from each

mount half Carefully trim any extra material left by the

spreader bar from each mount half The surfaces where the

spreader bars were attached must be smooth to allow the

mount halves to fit together Trim the flashing off any rough

edges if necessary Assemble the mount halves as shown.

Note: The procedures for mounting the 2-stroke and

4-stroke are the same.

D 6 While you still have an open, accessible structure,

inspect all glue Joints, making sure all formers, doublers,

tank floors and cabin brace are securely bonded Apply

fillets of medium or thick CA where required.

D 1. Attach the engine mount to the firewall using the

4 - 40 x 1" phillips head machine screws, # 4 washers

and lock washers provided.

D 7. Sand the tab on the cabin brace flush with the aft

side of former F2A.

Before we continue, now is the best time to fuelproof the

fuel tank compartment We recommend brushing on one of

the following 30-minute epoxy thinned with a little alcohol,

polyester resin, or fuelproof paint or dope We'll fuelproof

the exterior of the firewall/engine compartment later.

Also, you need to decide if you want your engine side

mounted or inverted Side mounting is recommended for

the 20- 26 4-stroke, but an inverted engine will allow you to

use two dummy engines on the cowl Mounting the 15-25

2-stroke inverted is recommended If you have elected to

use the Great Planes adjustable engine mount included in

the kit, you may easily mount the engine on its side or

inverted as the mounting holes are symmetrical This

allows repositioning the engine without drilling new engine

mounting holes in the firewall.

(Top and bottom sheeting shown in photo will be added later)

D 2 Install a straight piece of scrap plywood against the

drive washer on the engine Locate the engine on the

engine mount so the distance between the firewall and the

aft edge of the piece of scrap plywood is 4-1/8" (105mm).

Mark the mounting screw locations on the engine mount

(see the expert tip)

23