Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 8

30-minute epoxy is used

for extra strength (because

it can penetrate longer) and

where several parts must

be aligned and checked

before it cures. Working

time is about 25 minutes,

handling time 2 hours, and

it's fully cured in 8 hours.

Great Planes Pro" Wood Glue is an Aliphatic resin glue

that works well on all types of wood. It is non-toxic, virtually

odorless and dries clear. Some people are sensitive to CA

and epoxy fumes, so this is a good alternative for general

modeling use. Its only drawback is that it is slow to cure,

requiring the parts to be securely clamped, pinned or taped

while the glue dries.

Okay, you've got your work space ready, your tools are at

hand, and you know how to choose and use the right glue

for the job. Let's get started!

D 1. Unroll the plan sheets. Reroll the plan sheets inside

out to make them lie flat.

D 2. Remove all parts from the box. As you do, determine

the name of each part by comparing it with the plan and the

parts list included with this kit. Using a felt-tip or ball point

pen, lightly write the part name or size on each piece to

avoid confusion later. Use the die-cut patterns shown on

pages 6 and 7 to identify the die-cut parts and mark them

before removing them from the sheet. Save all scraps. If

any of the die-cut parts are difficult to punch out, do not

force them! Instead, cut around the parts with a hobby

knife. After punching out the die-cut parts, use your T-Bar

or sanding block to lightly sand the edges to remove any

die-cutting irregularities.

D 3. As you identify and mark the parts, separate them

into groups, such as fuse (fuselage), wing, fin, stab

(stabilizer), and hardware.

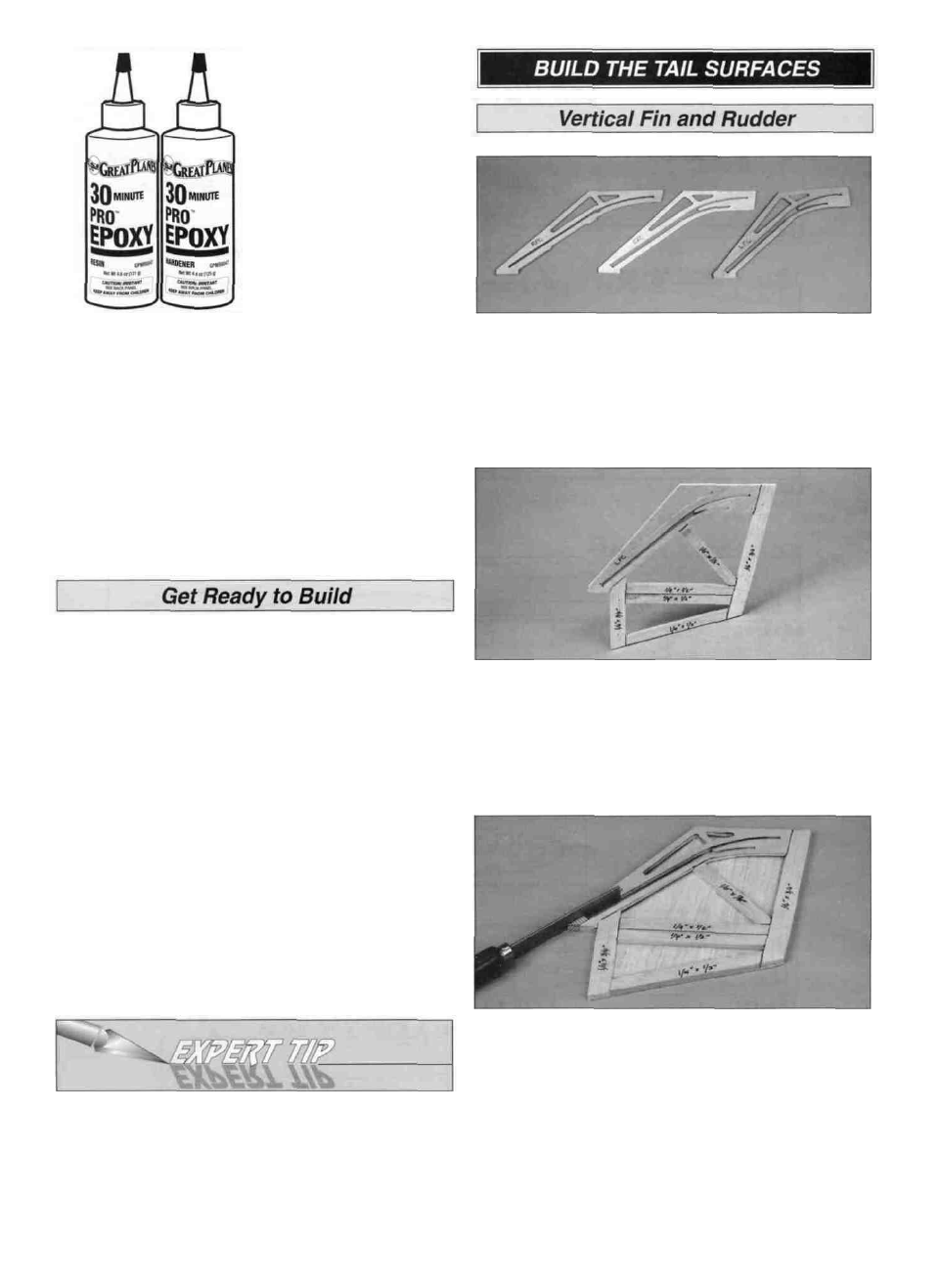

D 1. The fin core is made up of left and right die-cut 1/8"

plywood fin cores (LFC, RFC) and a die-cut 1/16" balsa

center fin core (CFC). Place the fin plan on your building

board and cover it with waxed paper. Place the 1/8" RFC

(with one slot) over the plan and glue the 1/16" center fin

core on top of it. Glue the 1/8" LFC (two slots) on top of the

center fin core.

D 2. Sand the front and top edges of the fin core smooth,

then pin the core over the plan. Assemble the balsa fin

framework from 1/4" x 1/2" and 1/4" x 3/4" balsa sticks on

the core as shown on the plan. Note: The frame is thinner

than the fin core but this will not cause a problem. Do not

install the leading edge, dorsal fin or the 3/8" top and rear

pieces yet.

Zipper-top food storage bags are handy to store your parts

as you sort, identify and separate them into subassemblies.

D 3. Remove the fin from the board, sand both sides

smooth (it's OK if the plywood core is a little thicker than

the balsa framing). Sheet the right side with 1/16" balsa

sheeting. Drill a 1/8" hole through the sheeting at the rear

end of the top slot and elongate the hole to fit the control

cable tubing. Cut away the fin core below the bottom of the

slots as shown on the plan.

8