Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 11

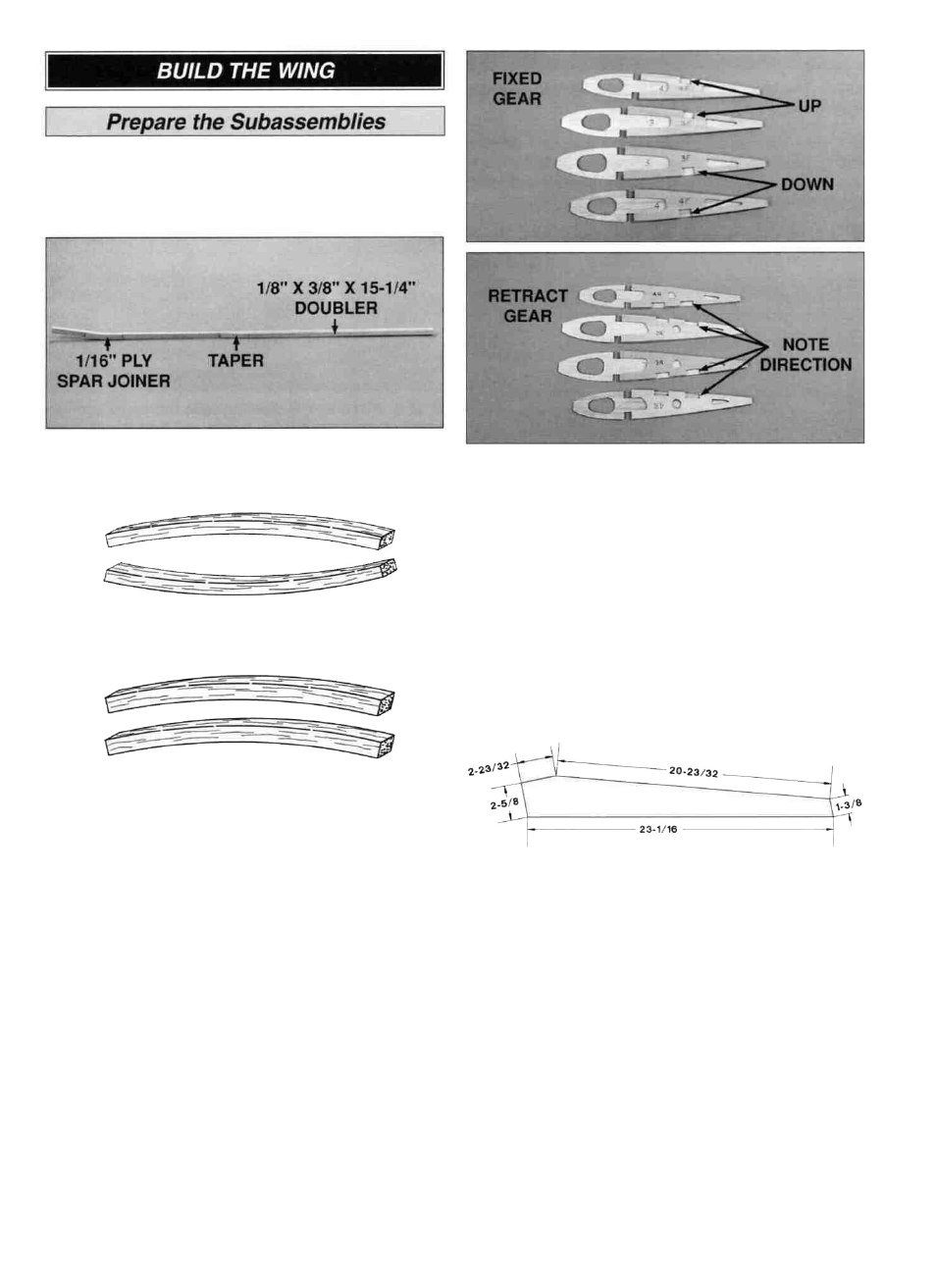

D 1. Pin the wing plan to your building board and cover it

with waxed paper.

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

STRAIGHT WING

TWO WARPED SPARS INSTALLED

THIS WAY WILL RESULT IN A

WARPED WING

D 5. Decide whether you will be using fixed or retractable

landing gear. The rib doublers required for fixed or retract

gear are different. W-3F and W-4F are used for the fixed

gear and W-3R and W-4R are used for the retract gear.

Glue the appropriate doublers to the W-3 and W-4 ribs,

being sure that you make a left and a right of each one.

Cut the gear block notches out of each rib using the

notches in the doubler as a guide.

D 6. Align the shaped and notched leading edges (LE)

over the plan. Cut the LE in two at the centerline of W-9.

Save both pieces.

D 2. Assemble the spars as follows: Pin one of the 1/4" x

3/8" x 30" balsa main spars down over one wing plan and

trim the outboard end at the centerline of W-9 (save the

off-cut piece for use in a moment). Locate a 1/8" x 3/8" x

15-1/4" balsa spar doubler. Sand 2-1/4" of one end of the

spar doubler to a taper (see plan). Glue the spar doubler to

the inboard end of the main spar so that the untapered end

is flush with the root end of the main spar. Trim the

off-cut piece of 1/4" x 3/8" to match the plan at the outboard

end of the main spar, then glue it in position. Glue the die-

cut 1/16" plywood spar joiner on top of the joint.

D 3. Remove this spar from the plan, then assemble a

second one over the same plan.

D 4. Build two more spars over the plan of the other

wing. This procedure will produce left and right top and

bottom spars.

CUT LE SHEETING AS SHOWN (4 REQUIRED)

D 7. Using the plan and the pattern shown above, cut four

3/32" x 3-1/2" x 30" balsa LE sheets. Note: The aft edge of

the sheets should fall approximately along the middle of

the spar.

D 8. Glue the two die-cut plywood dihedral braces (DB)

together with 6-minute epoxy. Be sure they are perfectly

aligned along all edges. Clamp the pieces together while

the epoxy cures.

D 9. After the DB epoxy has cured, lightly sand the edges

to remove any bumps. Drill a 1/4" hole through the DB

at each of the two punch marks. These holes are for the

wing dowels.

11