Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 36

D 1 Assemble and install an eight ounce fuel tank

according to the manufacturer's instructions.

D 2 Install the tank by placing it on a piece of 1/4" foam

rubber on the tank floor, then securing it in position

with rubber bands.

D 3 Route the supply and pressure tubes to the engine and

muffler pressure tap Be sure there are no kinks in the tubes

Perform steps 1 thru 7 if installing retracts. Skip this

section if installing fixed gear.

D 4.Pull the retract pushrods to the stops This will lock

the gear in the down position Mark the pushrod about

1/8" short of the servo case Make a 90 degree bend in

the pushrods, out and away from the surface of the wing.

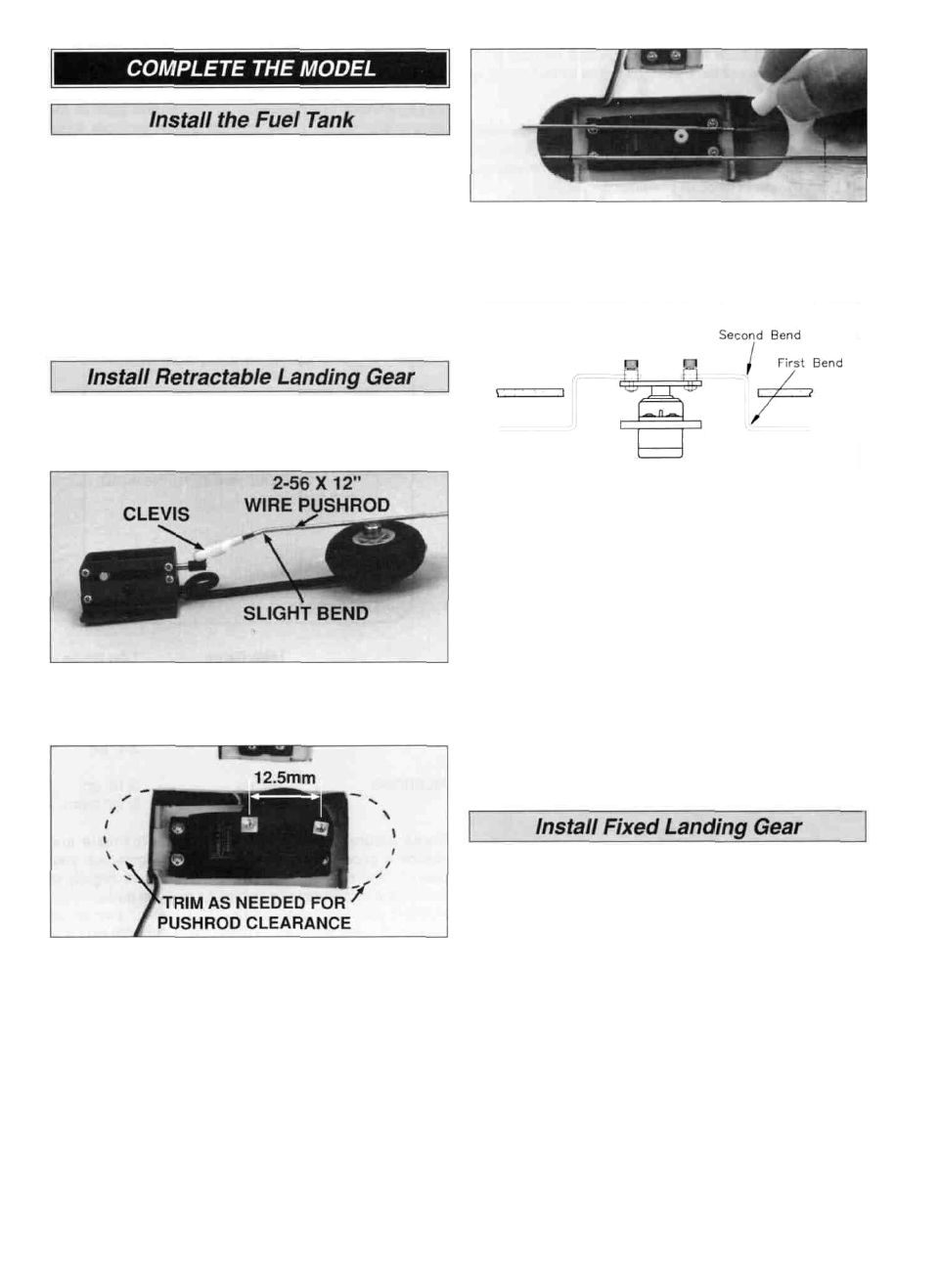

D 1 Assemble the retract pushrods with the materials

specified at the front of this manual Temporarily install your

retract servo (Futaba 135G low profile servo recommended)

D 2. A large round servo horn with holes drilled 12 5mm

from the center is suitable for most retract actuation

Install screw-lock pushrod connectors (not included,

GPMQ3870 recommended) onto the horn as shown

Install the servo horn on the servo, then mount the servo

in the wing

D 3 Connect the pushrods to the retracts, then insert

the pushrods through the clearance holes toward the

servo. Mount the retracts with #4 x 1/2" sheet metal

screws (not included).

D 5 Make another bend in each pushrod about 5/16"

above the first, to point the pushrod ends toward the

pushrod connectors on the servo

D 6 Hook up and cycle the retracts a few times to make

sure that there is no interference or binding in the

linkage Make minor adjustments as required Trim off the

excess pushrod wire at the servo once satisfied with the

retracts operation NOTE: 4-40 set screws should be

substituted for the socket head cap screws supplied with

the screw-lock pushrod connector.

D 7 Install and hook up the nose wheel retract as you

did during construction, then connect the steering cable

to the steering arm with a metal clevis.

D 1 Insert the torque rod portion of the main wire landing

gear (the shorter end) into the LG blocks in the bottom of

the wings Use the straps and plan as guides, then drill

1/16" pilot holes for the screws Attach the gear legs with

two nylon landing gear straps and four #2 x 3/8" sheet

metal screws per gear.

D 2 Refer to the cross section of the firewall on the plan,

then install the nose gear using the supplied 5/32' wheel

collar and set screw and the nylon steering arm/wheel

collar assembly Install a screw-lock pushrod connector

upside down in the last hole of the steering arm securing it

with a locking washer Connect the steering arm to the

braided wire steering cable and secure it with a 4-40 x 1/8"

cap screw

36