Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 34

will result in a cleaner hole than if you use a slower speed

power or hand drill Drilling the hole will twist some of the

wood fibers into the slot, making it difficult to insert the

hinge, so you should reinsert the knife blade, working it

back and forth a few times to clean out the slot.

D 6 Install the control horns on both elevators and rudder

in the location shown on the fuse plan Mark the mounting

holes, then drill through the control surface with a 3/32" bit

at each mark Apply a couple of drops of thin CA into each

hole to strengthen them When the CA has cured, mount all

of the horns using 2-56 x 1/2" machine screws

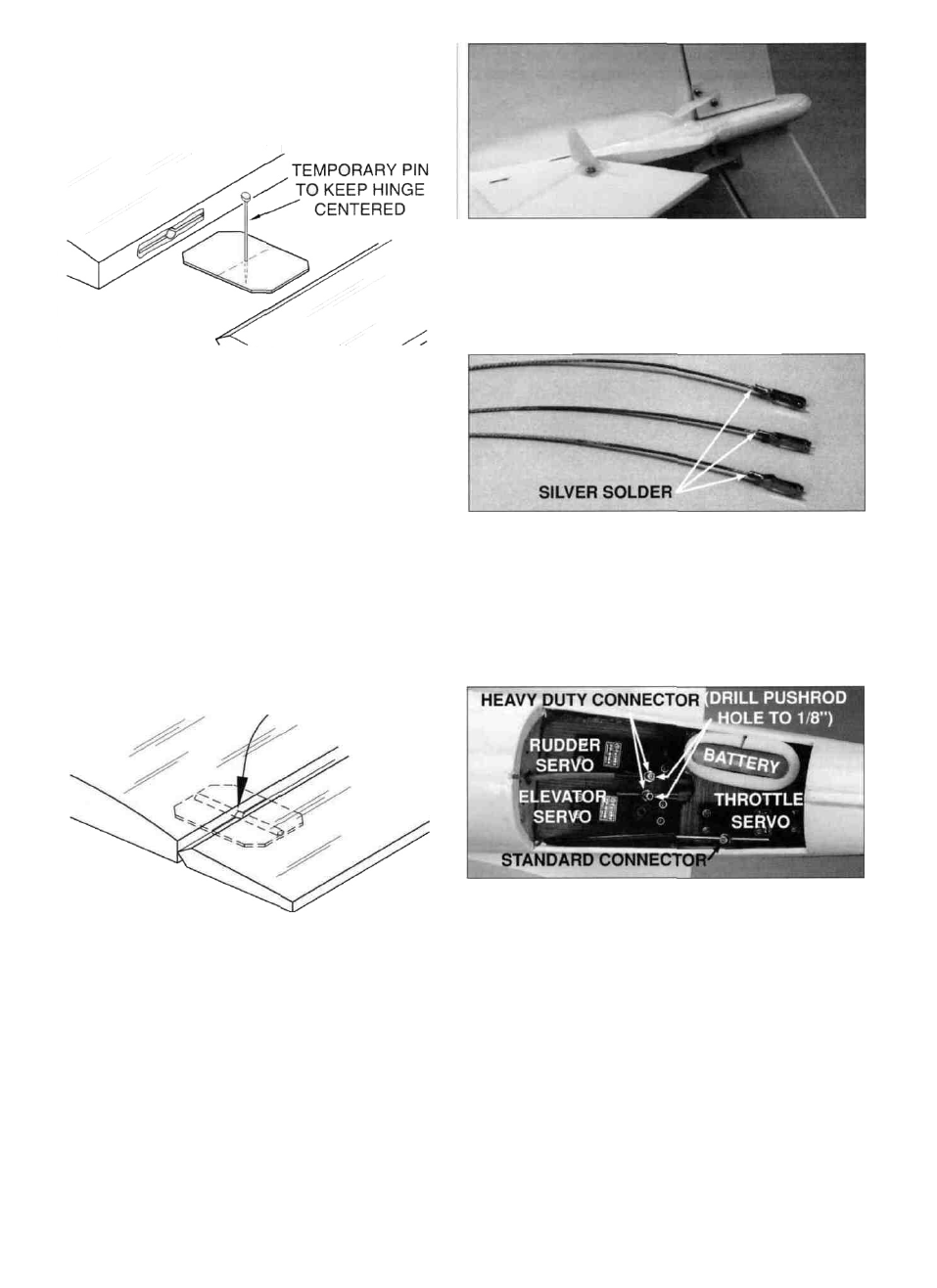

C Insert the hinges and install the control surface Verify

the left-right positioning of the control surface, and close

up the hinge gap to 1/32" or less It is best to leave a

very slight hinge gap, rather than closing it up tight, to

help prevent the CA from wicking along the hinge line

Make sure the control surface will deflect to the

recommended throws without binding If you have cut

your hinge slots too deep, the hinges may slide in too far,

leaving only a small portion of the hinge in the control

surface To avoid this, you may insert a small pin

through the center of each hinge, before installing This

pin will keep the hinge centered while installing the

control surface Remove the pins before proceeding

D 7 Cut three pieces of braided cable to 18" long Use

silver solder (GPMR8070) to solder a metal clevis to one end

of each cable If installing retracts, solder an additional

metal clevis (not included, GPMQ3810) to one end of a 36"

cable This cable will be used for the nose wheel steering.

NOTE: Because of the acidic nature of the flux, you must

thoroughly clean each joint after soldering to avoid

destructive corrosion Lightly oil the cable after cleaning

ASSEMBLE THEN APPLY 6 DROPS

OF THIN CA TO CENTER

OF HINGE, ON BOTH SIDES

D 4 Apply 6 drops of thin CA adhesive to both sides of

each hinge on the elevators and rudder only - not the

ailerons yet. Allow a few seconds between drops for the

CA to wick into the slot Note that the small "tunnels" you

created by drilling the 3/32" holes allow the CA to freely

travel in to the entire surface of the hinge, producing an

extremely secure bond.

D 5. Pack each of the torque rod holes in the ailerons with

30-minute epoxy (a toothpick works well for this), then

install the ailerons with their hinges Repeat the gluing

technique described in step 9 and allow the epoxy to cure

REFER TO THIS PHOTO FOR THE NEXT 6 STEPS

D 8 Drill through the pushrod hole of both heavy duty

screw lock pushrod connectors with a 1/8" drill bit Install

the connectors on the rudder and elevator servo horns but

don't install the locking washer until after the control throws

are adjusted Install the horns on the servos Install a

standard screw-lock pushrod connector on the throttle

servo horn. Once again, don't use the locking washer

D 9 Slide a silicone clevis retainer onto each clevis, then

insert the rudder and elevator cables into their guide tubes

from the control surface end Thread them into the

connectors on the servos. Both of the elevator cables fit

into one hole.

34