Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 17

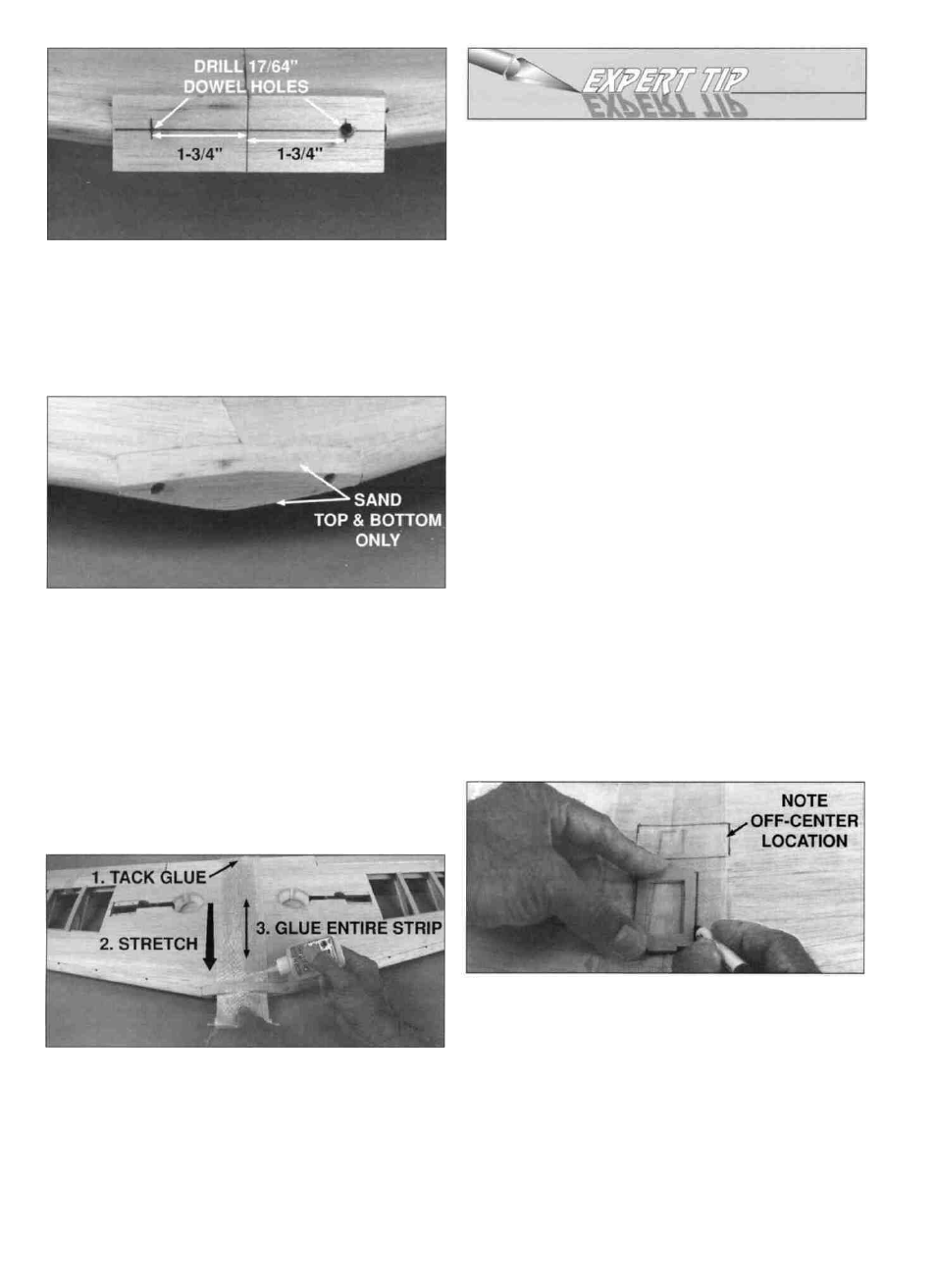

D 5. Draw a horizontal line across the front of the center

leading edge block. Mark the centerline of the wing on the

front of the block. Make a mark 1-3/4" on each side of the

centerline. These marks show the position of the 1/4" wing

dowels. Drill a 17/64" hole through the block at each of

the marks.

D 6. Carve and sand the top and bottom edges of the

block to follow the airfoil contour but leave the front

surface flat.

Applying Fiberglass Cloth

A. Center one end of the fiberglass cloth on the trailing

edge of the wing, then apply several drops of thin CA to

hold it in position. Roll the loose end of the fiberglass cloth

onto a pencil, then use the pencil as a handle to stretch

the cloth over the wing toward the leading edge. Apply a

few more drops of thin CA to the LE to hold the cloth in its

"stretched tight" position.

B. Make a squeegee by wrapping a 2" wide piece of stiff

cardboard with a plastic sandwich bag or similar material.

Perform the following operation in a well ventilated

area with a fan directing air flow away from you.

C. Starting at the trailing edge, flow thin CA into the cloth.

Smooth the cloth down with the squeegee as you work

toward the leading edge. Avoid standing directly over the

work as the CA fumes can be quite irritating to your eyes

and nose.

D. Allow the CA to cure naturally without using any

accelerator. When thoroughly cured, lightly sand the

edges with 150-grit sandpaper to remove any ridges.

E. Just before you cover your model, fill the weave and

blend the edges with the wing using balsa filler. Sand the

dried filler with 220-grit sandpaper and recoat if necessary.

D 7. Round one end of each 1/4" x 4" wing dowel and

chamfer the other end (to make it easier to insert). Test fit

the dowels into the wing to be sure that they pass easily

through the leading edge block and the dihedral brace.

Glue them in place with 30-minute epoxy.

D 8. Apply 3" wide fiberglass cloth to the center joint on

the top and bottom of the wing. We prefer to adhere the

cloth with thin CA to save weight, but resin or thinned epoxy

will work just as well. Read the Expert Tip that follows

before performing step #8.

D 9. NOTE: The aileron and retract servo trays are slightly

different in size - the aileron servo tray is the smaller one.

Center the die-cut plywood aileron servo tray on top of the

wing at the marks you made in siep 5 of the previous

section (Completing the wing panels). Mark the outside

perimeter of the tray, then cut the wing sheeting from inside

the lines. Refer to the wing plan to locate the retract servo

tray opening. Mark and cut the sheeting for the retract

servo tray.

17