Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 30

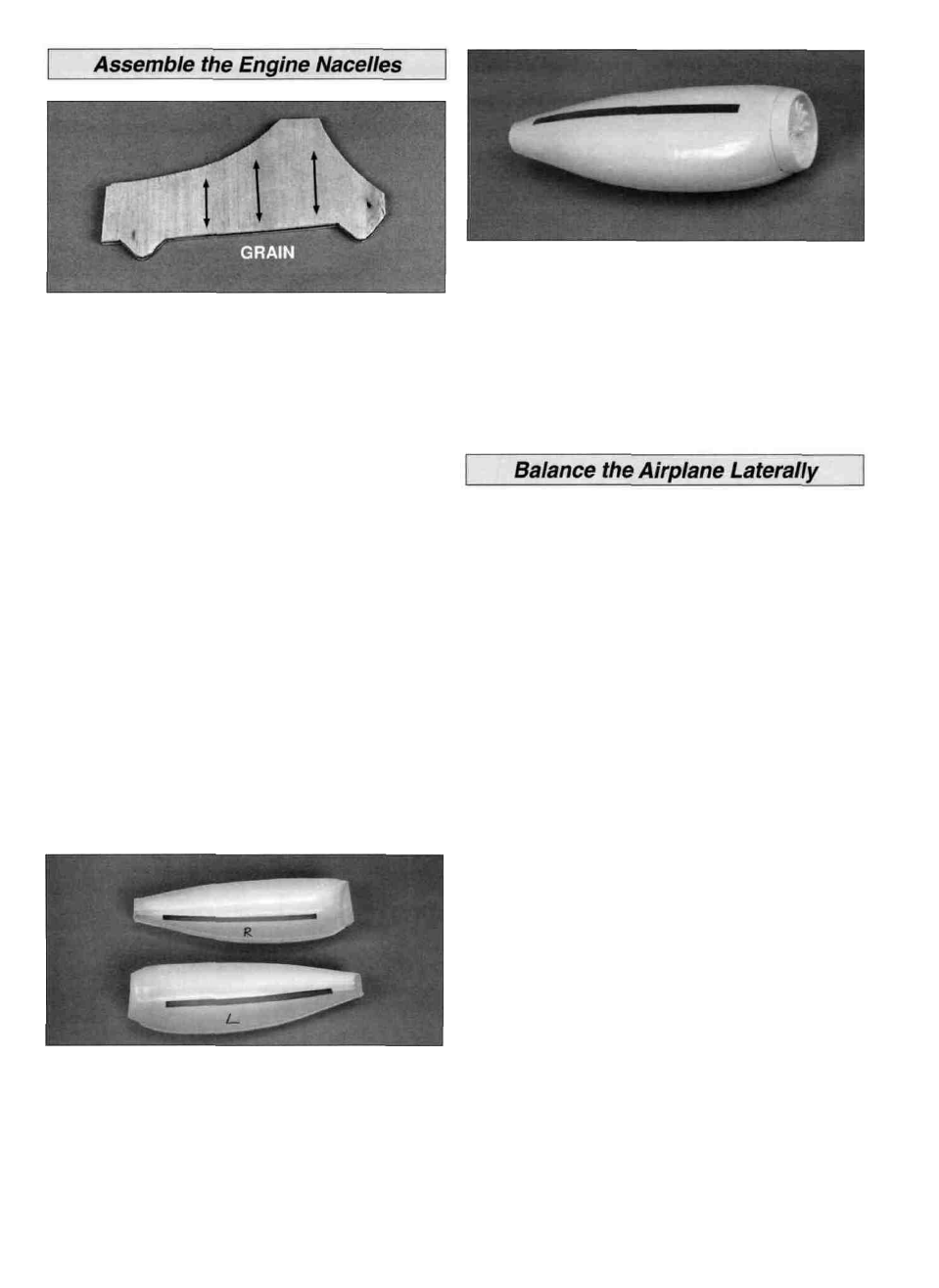

D 1. Sheet both die-cut 1/8" plywood nacelle pylons on

both sides with 3/32" x 3" balsa. Be sure the grain direction

runs from the inboard edge to the tip. Trim and sand the

sheeting to the shape of the die-cut pylons.

D 5. Roughen the mating surfaces with coarse sandpaper

then glue the left, right and front pieces together with thin CA.

D 6. If you will be painting the nacelles, now would be a

good time to fill the joints with automotive body filler (Bondo).

Wet sand the seams smooth before priming and painting.

D 2. Insert the pylons into the slots in the fuse, then cut two

pylon trailing edge pieces from the remaining balsa rudder

stock to the shape shown on the plan. Sand the edges for a

nice fit with the fuse sides. Glue the TE pieces to the

pylons only. We will glue them to the fuse after the model

is covered.

NOTE: Do not confuse this procedure with "checking

the C.G." or "balancing the airplane fore and aft." That

very important step will be covered later in the manual.

Now that you have the basic airframe nearly completed,

this is a good time to balance the airplane laterally (side-

to-side). Here is how to do it:

D 3. Trim the six pieces that comprise the dummy engine

nacelles to the embossed cut lines. Sand the edges smooth.

Without gluing, fit the parts together, then designate the left

and right nacelles. Open the two nacelles.

D 1. Temporarily attach the wing and engine (with muffler)

to the fuselage.

D 2. With the wing level, lift the model by the engine

propeller shaft and the fin post (this may require two

people). Do this several times.

D 4. Cut a pylon access slot in only the two pieces that

will be closest to the fuselage following the embossed cut

lines on the inside surface of the nacelles. Do not cut the

slots in all four pieces or you will have slots showing on

the outside of the nacelle.

D 3. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by gluing

weight to the other wing tip. NOTE: An airplane that has

been laterally balanced will track better in loops and

other maneuvers.

There. The assembly is done! If you have followed the

instructions and Expert Tips you should be looking at a

pretty spiffy Learjet airframe. From here on you should

work over a soft pad of foam or bathroom towels to prevent

creating new dings in the structure. Clean off your

workbench and vacuum up any balsa dust and wood chips

as they have a way of causing scratches on the covering as

you apply it.

30