Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 16

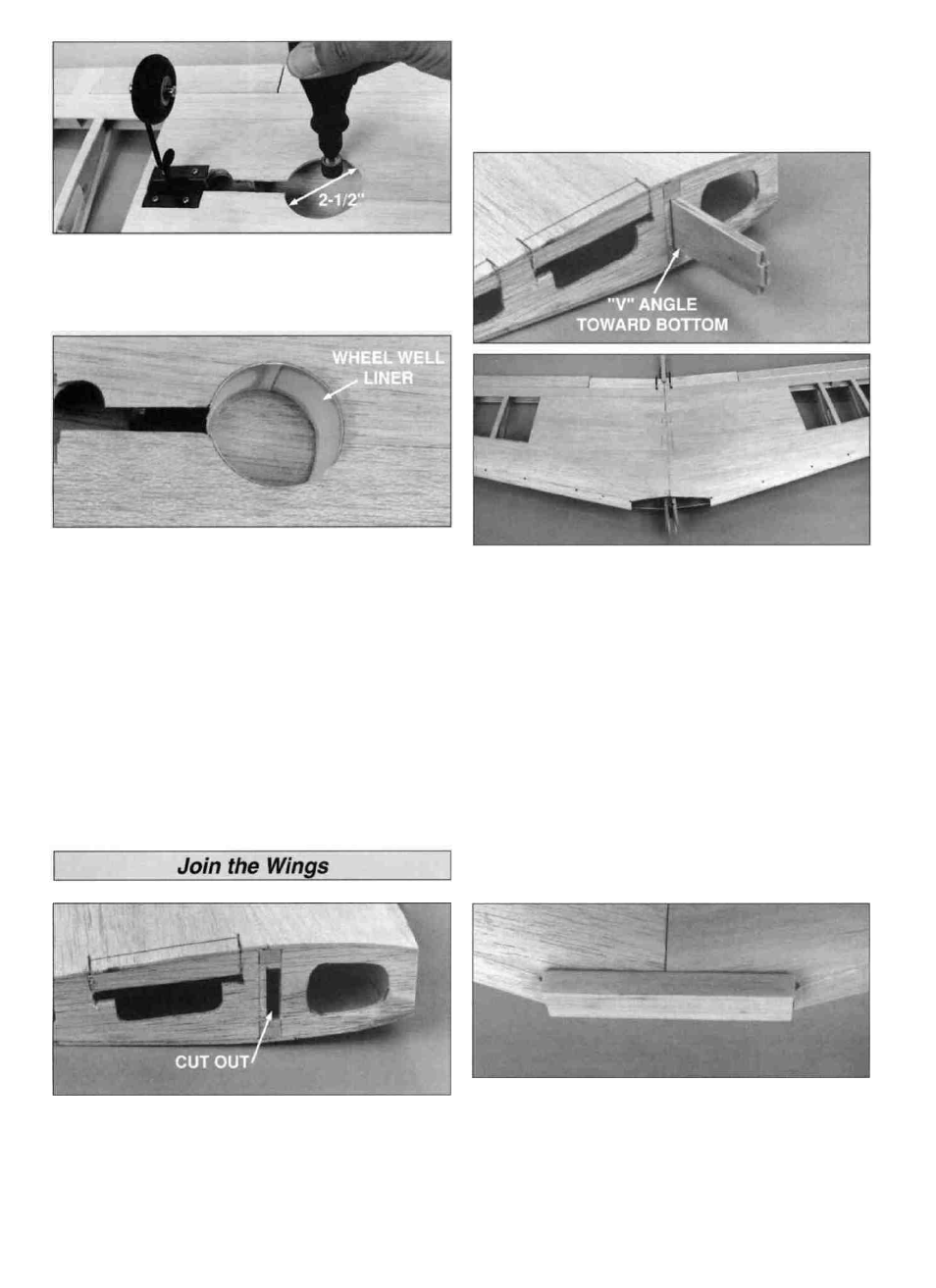

D 7. Slowly retract each strut and wheel, cutting away

the bottom center sheeting and ribs for clearance as you

go. Enlarge the diameter of the wheel well hole to 2-1/2"

keeping the hole centered on the retracted wheel.

D 8. The wheel well liners can be made from proper

sized foam or paper coffee cups, or from vertical grain

1/16" balsa sheeting wrapped around an appropriately

sized glass jar and glued to form a cylinder. Glue the

wheel wells in place, then trim the edges to match the

bottom sheeting.

D 9. Use a 12" long x 1/4" drill bit to drill a hole from the

retract servo opening, through the wheel well liners, to

the retract mechanism.

D 2. If needed, sand the leading edge sheeting even with

the front edge of W-1.

D 3 Before using any glue,trial fit the wings together using

the die-cut plywood dihedral brace (DB). The wing roots

(W-1) should fit together smoothly, and the dihedral brace

should contact both spars and also locks into both W-2s.

The dihedral brace is mounted perpendicular to W-1, not

parallel to the spars (see plan for exact position) Be sure

the "V" shaped edge of the dihedral brace is toward the

bottom of the wing. Apply 30-minute epoxy to the mating

surfaces of the W-1 ribs, dihedral brace and inner edges of

the center TE. Clamp or pin the wings together while the

epoxy cures.

NOTE: When the epoxy has cured, look at (DB) from the

leading edge and add additional epoxy to fill any visible gaps.

D 1 Finish cutting out the partially die-cut section

between the spars on both W-1 ribs.

D 4. Fit and install the 1/2" x 1-7/16" x 5" balsa center

leading edge block. We suggest using a liberal amount of

thick CA when you glue it in position.

16