Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 26

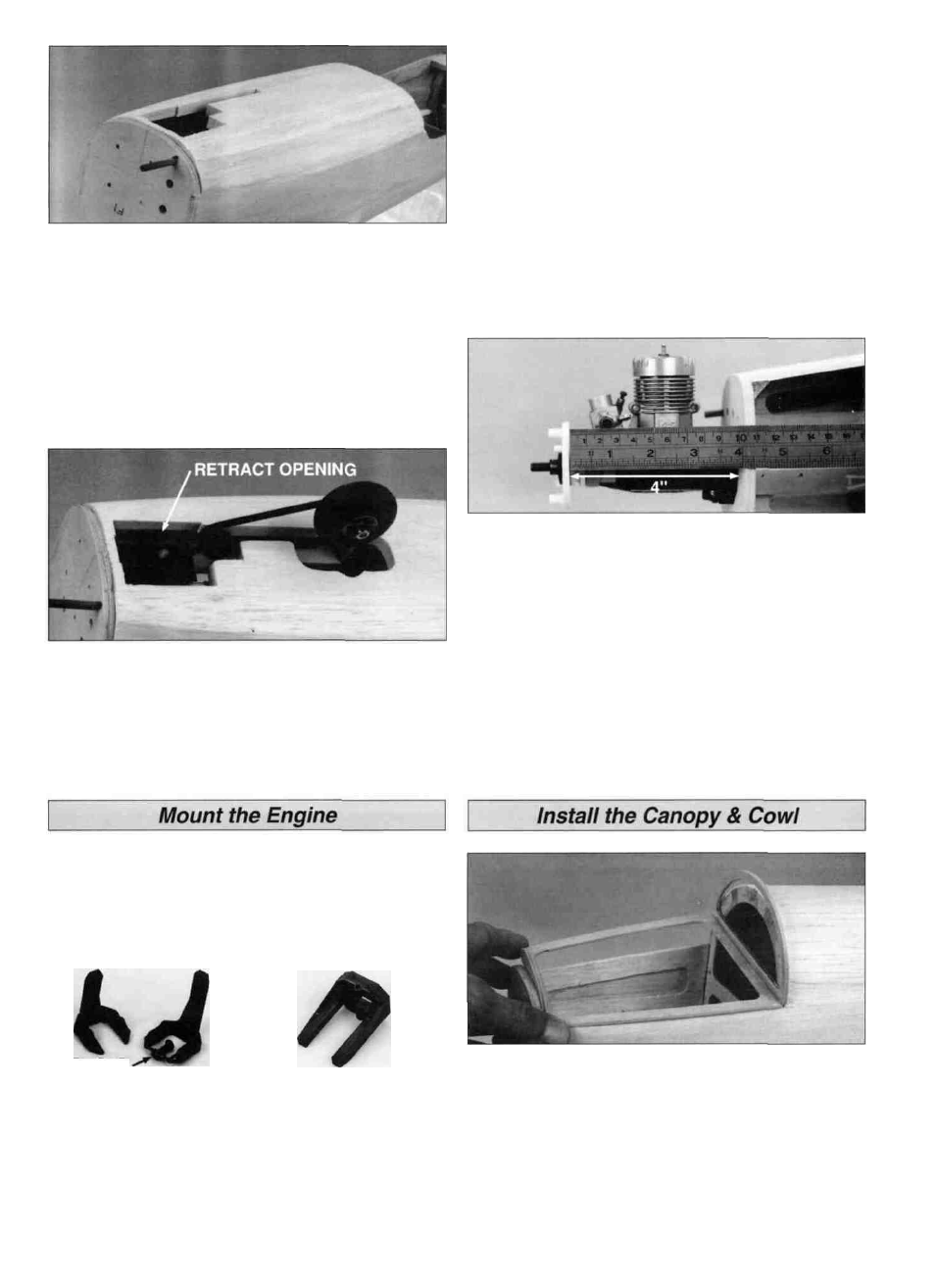

D 40. Remove the retract mechanism. Trim and sand the

tops of the F-8s flush with the top of F-1 D, F-2A and F-3A,

then glue the 1/2" x 4" x 13" balsa front bottom block in

place. If you are using retracts, cut a clearance hole for the

retract mechanism in the block. HINT: To locate the position

of the retract mechanism, push a sharpened piece of wire

through the retract screw holes in the tank floor out through

the bottom of the block. Align the retract mechanism over

the holes, then mark its shape. Carve off the overhanging

portions of the fuse bottom and roughly create the

rounded shape.

D 41. If you are using retracts, reinstall the retract unit,

axle and wheel. Slowly retract the gear while you cut away

the portions of the bottom block which interfere. A template

has been provided on the fuse plan for reference. Cycle the

retract a few times to be sure that everything works

correctly, then remove the retract assembly.

bars were attached must be smooth to allow the mount

halves to fit together. Trim the flashing from any rough

edges if necessary. Assemble the mount halves as shown.

D 2. Temporarily install the engine mount on the firewall

using four #4 flat washers and four 4-40 x 1" machine

screws. Don't tighten the screws completely until after the

engine has been positioned.

D 3. Position the engine on the engine mount. Slide the

engine mount halves apart until the engine mounting lugs

will sit flat on the rails. Adjust the mount up and down until

the tic marks on the mount are centered on the horizontal

reference line on the firewall. After adjusting the mount,

tighten the 4-40 screws to hold it firmly in position.

D 4. Position the engine so that the backplate of a spinner

will be 4" (102mm) in front of the firewall. Carefully mark

the engine mounting holes on the rails with a sharpened

piece of wire or a pencil lead.

D 5. Remove the engine and engine mount from the fuse.

Use a centerpunch or sharpened nail to "dimple" the marks

on the rails, then drill a 7/64" hole through the rails at each

punch mark. If you have access to a drill press, this is the

best tool for the job. However, if you are using a hand held

electric drill, try to keep the bit perpendicular to the rails.

Test fit the engine but don't screw it permanently in position

just yet.

The Great Planes adjustable engine mount is simple and

convenient to use. It may be used to mount most .20 - .40

two-stroke and .26 - .48 four-stroke engines. Nose gear

bearings for 5/32" diameter wire are incorporated in the

mount.

REMOVE

D 1. Cut or break the "spreader bar" from each mount half.

Carefully trim any extra material left by the spreader bar

from each mount half as the surface where the spreader

D 1. Protect the edges of the fuse and formers with waxed

paper, then fit the die-cut 1/8" ply canopy base between F-

1 and F-2. Glue the die-cut 1/8" ply C-1 and C-2 to the

canopy base using F-1 and F-2 to set the proper angles. Be

careful not to glue the canopy base to the fuselage.

26