Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 33

D 3 Wrap the battery in 1/4" foam, then install it in the

opening in the servo compartment. Connect the battery to

the switch.

D 4 Center all of the trim levers on your transmitter, then

turn on the transmitter and the receiver. Manually center all

of the servo horns.

D 5. Use some scrap balsa to make a tray to support and

secure the receiver.

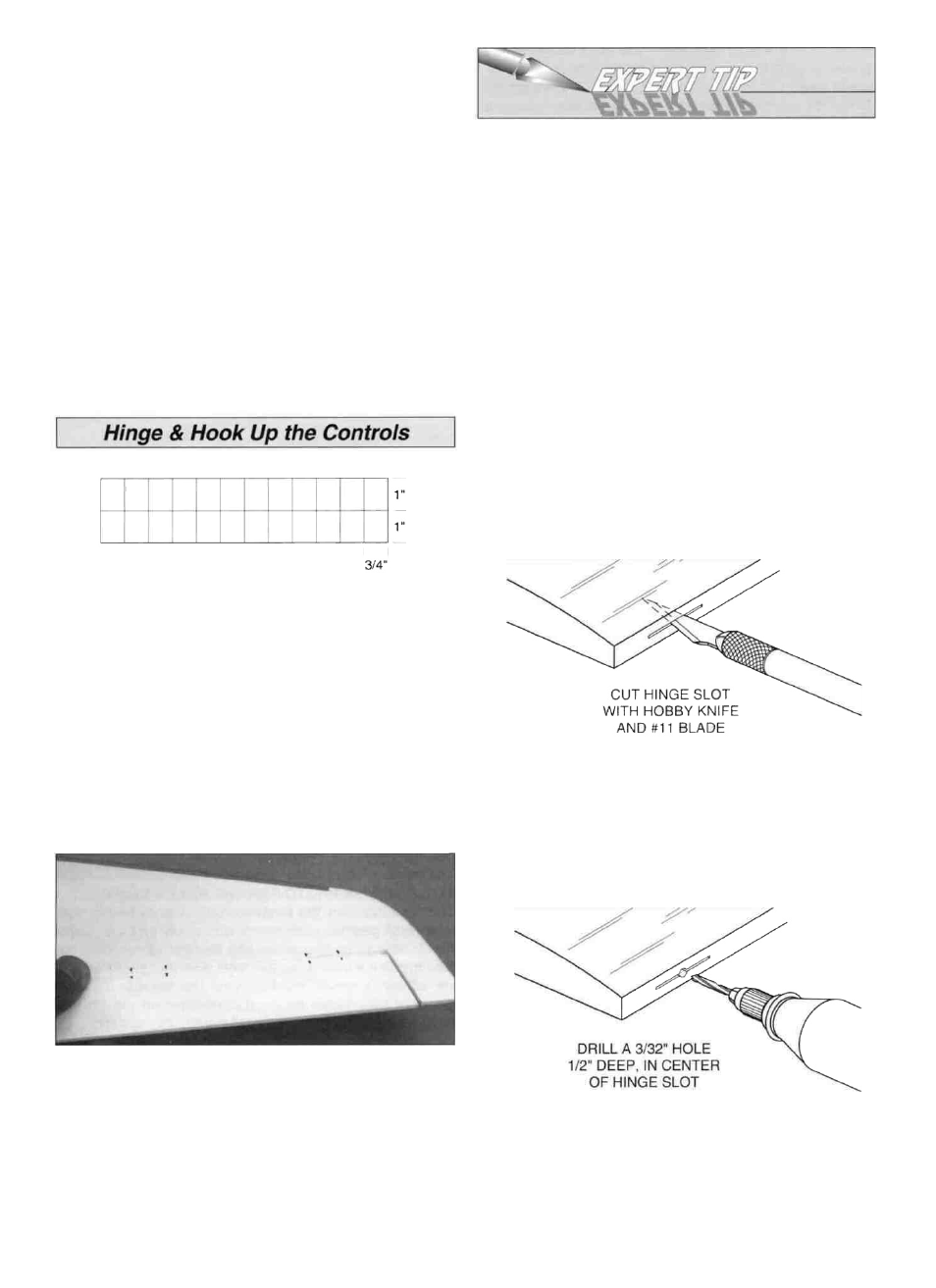

D 1. With reference to the above sketch, cut 18 hinges

from the supplied 2" x 9" composite hinge material You will

need six hinges for the elevators and two for the rudder.

Each aileron gets four hinges

D 2 Draw a centerline on the TE of the stab and the LE of

the elevators. Do the same for the fin and rudder.

D 3 Use the plan as a guide to mark the locations of the

hinges on all tail components - fin, rudder, stab, elevator,

the wings' TE and the ailerons Refer to the Expert Tip that

follows, then cut matching hinge slits in all parts Do not

use any glue until step 4.

INSTALLING CA HINGES

The hinge material supplied in this kit consists of a

3-Iayer lamination of mylar and polyester It is specially

made for the purpose of hinging model airplane control

surfaces. Properly installed, this type of hinge provides

the best combination of strength, durability and ease of

installation We trust even our best show models to these

hinges, but it is essential to install them correctly.

Please read the following instructions and follow them

carefully to obtain the best results These instructions

may be used to effectively install any of the various

brands of CA hinges.

The most common mistake made by modelers when

installing this type of hinge is not applying a sufficient

amount of glue to fully secure the hinge over its entire

surface area, or, the hinge slots are very tight, restricting

the flow of CA to the back of the hinges This results in

hinges that are only "tack glued" approximately 1/8" to 1/4"

into the hinge slots The following technique has been

developed to help ensure thorough and secure gluing.

A. Cut the hinge slot using a #11 blade in a standard #1

knife handle The CA hinges provided have a thickness

that fits this type of slot very well Trial fit the hinge into

the slot If the hinge does not slide in easily, work the

knife blade back and forth in the slot a few times to

provide more clearance (it is really the back edge of the

blade that does the work here in widening the slot)

B. Drill a 3/32" hole, 1/2" deep, in the center of the

hinge slot. If you use a Dremel Moto-Tool® for this task, it

33