Great Planes Learjet 40 Kit - GPMA0439 User Manual

Page 21

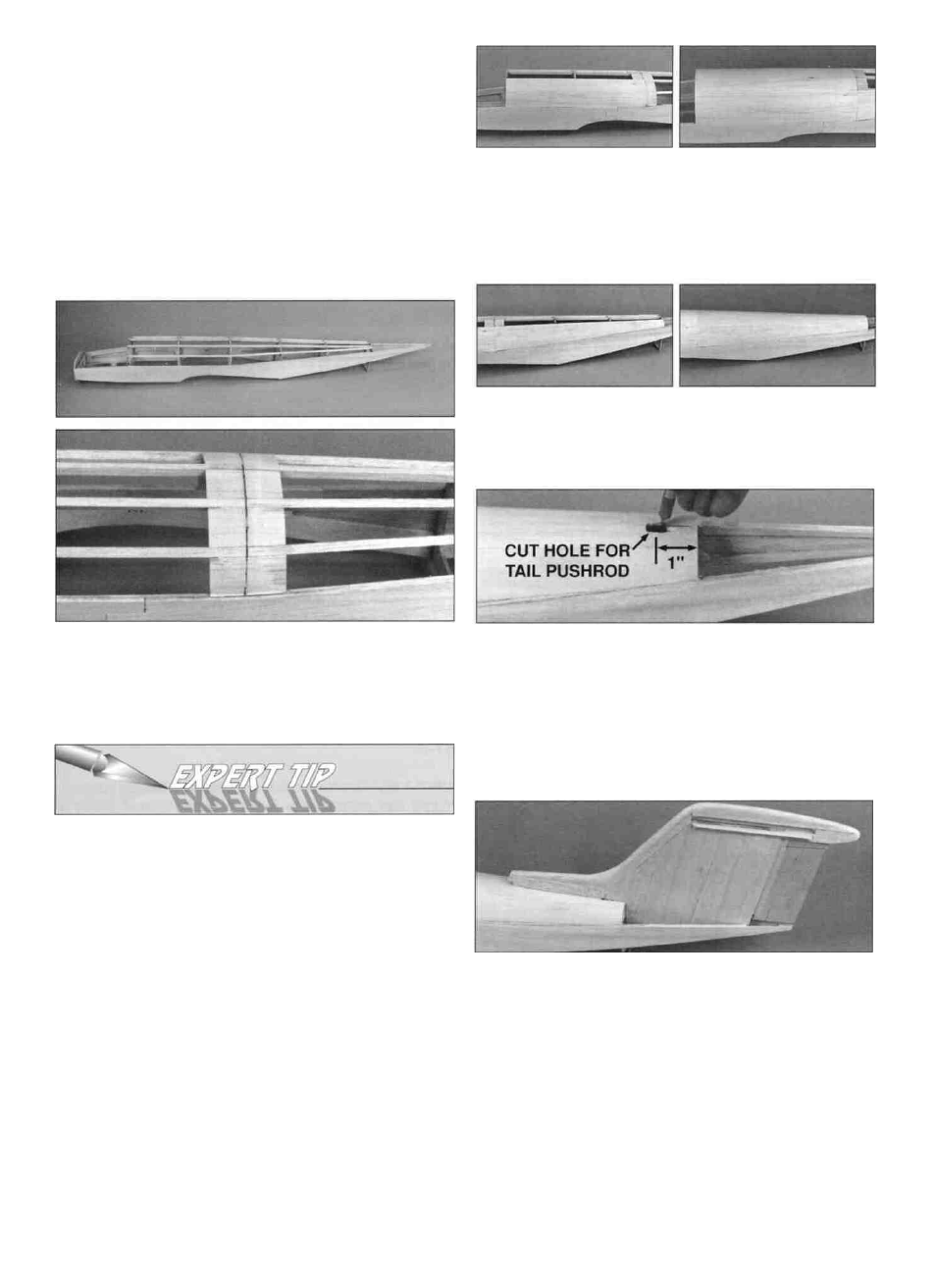

pulled in to meet it Wet the fuselage sides from F-2

forward, but keep the water away from the gluing surfaces.

Glue the firewall in place with 30-minute epoxy, then run a

bead of thick CA along the top edges of the tank floor Use

rubber bands or clamps to hold the sides together until the

epoxy cures Pin the fuselage sides to the board as close to

the firewall as you can to help keep the firewall centered

D 9 Without gluing, fit the 1/4" x 1/4" x 36" balsa top

stringers in the notches from F-2 to F-7 Mark the position

of F-4 on each stringer Cut halfway through the stringers

from the bottom so that they will make a clean bend at F-4

Glue all five stringers in place

D 11 Install the 3/32" x 3" x 13-1/8" forward top sheeting

from F-2 to F-4 Glue the first sheet to the top of the

fuselage side doubler and then trim it so that it extends to

the middle of the second stringer Wet the balsa if

necessary, then glue this sheet down Sheet the other

side. Fit and install the top sheet between them.

D 12 Install the 3/32" x 3" x 19-1/8" aft top sheeting the

same way as the forward sheeting, except that you may

find it easier to trim the side sheets roughly to shape before

gluing them to the top of the fuse doubler.

D 10 Center, then glue the 3/32" x 1-1/16" x 2" balsa

fillers between the stringers on both sides of F-4 Sand the

front and rear portions of the fillers and the tops of the

stringers so that the sheeting will lie flat on top of them

Sheeting a rounded surface.

Wet the outside of a balsa sheet, then flex it with the

grain for a minute or two to soften it up and start a curve

Align the sheet with the fuse side, then temporarily hold it

in place with clothespins

Mark the sheet for cutting Always trim the sheet to the

center of the appropriate stringer to allow for a gluing

surface for the next piece of sheeting

Apply medium or thick CA to all frame parts that the

sheet will contact. Roll the sheet into position, starting

along the lower edge Hold it in position by hand and with

clothespins until the CA cures Wick thin CA along the

top seam, wiping off the excess before it cures Repeat

for the other side of the fuse It's best to sheet alternate

sides to avoid building in a twist.

D 13 Trim and sand the top sheeting flush with F-2 and

F-7, then remove the fuse from the building board Cut a

3/8" diameter hole through the top sheeting and center

stringer 1" in front of F-7 for the tail surface pushrod tubes

NOTE: Before performing the following step, lightly draw a

centerline along the top of the fuse using the top center

stringer locations at F-2 and F-7 for reference.

D 14 Insert the completed vertical fin into the rear of the

fuselage Shim the rear of the fin so that it is centered

between the fuselage sides IMPORTANT: Carefully

check that the fin is lined up fore and aft with the

centerline of the fuselage Hold a 36" straightedge along

one side of the fin, then adjust the fin so that the

straightedge is parallel to the centerline on top of the fuse.

Be sure that the fin is perpendicular to the building board.

Mark the fin's position on the back of F-7, then pin it firmly

in place.

21