Electrical connections, Interfacing, Setup and calibration – Flintec FAD-30 User Manual

Page 32

FAD-30 Technical Manual, Rev. 1.06 December 2012

Page 32 of 48

6.2. Electrical Connections

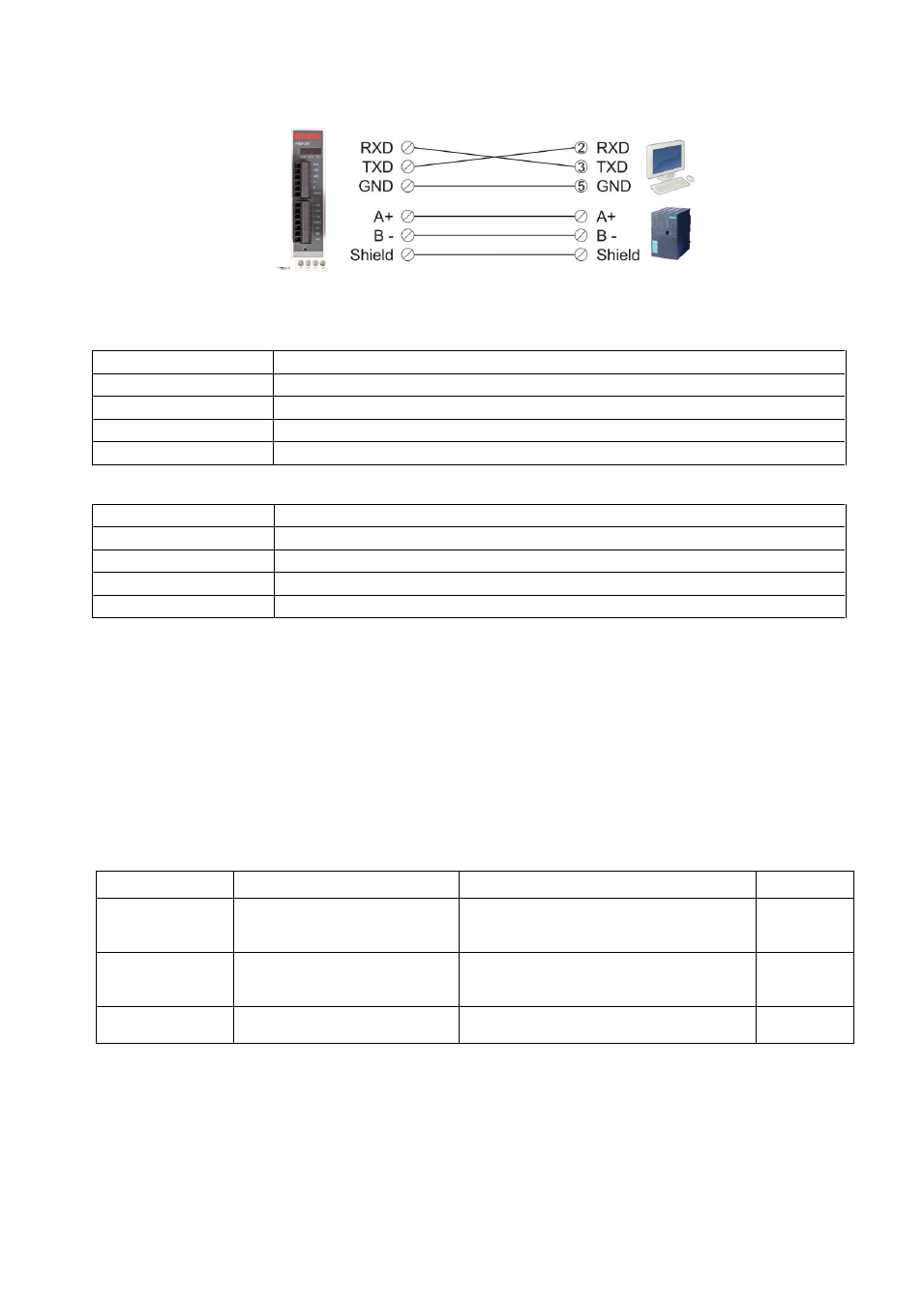

RS-232 and RS-485 connections are shown in figure 6.2.

Figure 6.2

– FAD-30 / FAD-30MB serial interface connections

RS-232C Serial Interface

Use

Interfacing with PC or PLC, setup via xFace

Data format

Continuous, BSI (Default)

Baud rate

9600 bps

Length and parity

8 bit, no parity

Start / Stop bits

1 start bit and 1stop bit

RS-485 Serial Interface

Use

Interfacing with PC or PLC, setup via xFace

Data format

Continuous, BSI (Default for FAD-30), Modbus RTU (for FAD-30MB only, default)

Baud rate

1200 / 2400 / 4800 / 9600 (Default) / 19200 / 38400 / 57600 bps

Length and parity

8 bit, no parity

Start / Stop bits

1 start bit and 1stop bit

Warning: Connect the shield to the reference ground.

Warning: Disconnect xFace PC software for Modbus-RTU interfacing

Load Cell Connection

See chapter 4.2.2

Power Supply Connection

See chapter 4.2.1

6.3. Interfacing

FAD-30 and FAD-30MB instruments have two serial interface connectors on the front of the instrument: RS-232

and RS-485. The table below describes the data format for interfacing the peripherals and their application:

Data Format

Description

Application

Hardware

Continuous

Asynchronous continuous

output. Refer to chapter 5.8

Continuous data transfer to PC or PLC

Remote display connection

Remote Taring, Zeroing

RS-232C

RS-485

BSI

Demand interface on BSI

Serial Interface format.

Refer to chapter 5.9

Master

– Slave data interfacing with

PLC or PC.

RS-232C

RS-485

Modbus RTU

(FAD-30MB only)

Modbus RTU interfacing.

Refer to chapter 5.10

Interfacing with PLC.

RS-485

Table 6.1

– Data output interfacing

Attention: Please disable the interface if not used to increase the performance of the instrument.

6.4. Setup and Calibration

FAD-30 and FAD-30MB instruments are set up and calibrated by xFace. The A/D Converter settings are very

important for a good weighing performance. Please refer to chapter 5.3.