AERCO Belimo F7...HD/HDU Series Valve User Manual

Page 40

800-543-9038 USA

866-805-7089 CANADA

203-791-8396 LATIN AMERICA

40

0

7/10 - Subject to change. © Belimo Air

controls (USA), Inc.

FLANGE BOLTING RECOMMENDATIONS

Lug Valves, 2”-30”, ANSI 125/150 Bolt Pattern

Valve Size

Thread Size

Number Required

Bolt Length Semi-Lug Butterfl y (inches)

2”

5/8-11

4

1.25

2-1/2”

5/8-11

4

1.50

3”

5/8-11

4

1.50

4”

5/8-11

8

1.75

5”

3/4-10

8

1.75

6”

3/4-10

8

2.00

8”

3/4-10

8

2.25

10”

7/8-9

12

2.25

12”

7/8-9

12

2.50

14”

1-8

12

2.75

16”

1-8

16

2.75

18”

1 1/8-7

16

3.50

20”

1 1/8-7

20

4.25

24”

1 1/4-7

20

4.75

30”

1 1/4-7

24

4.50

PRE-INSTALLATION PROCEDURE

1. Remove any protective fl ange covers from the valve.

2. Inspect the valve to be certain the waterway is free from dirt and

foreign matter. Be certain the adjoining pipeline is free from any

foreign material such as rust and pipe scale or welding slag that

could damage the seat and disc sealing surfaces.

3. Any actuator should be mounted on the valve prior to installation to

facilitate proper alignment of the disc in the valve seat.

4. Check the valve identifi cation tag for materials, and operating

pressure to be sure they are correct for the application.

Installation Recommendations

F6…HD(U), F7…HD(U) Series Butterfl y Valves

FLANGE BOLTING RECOMMENDATIONS

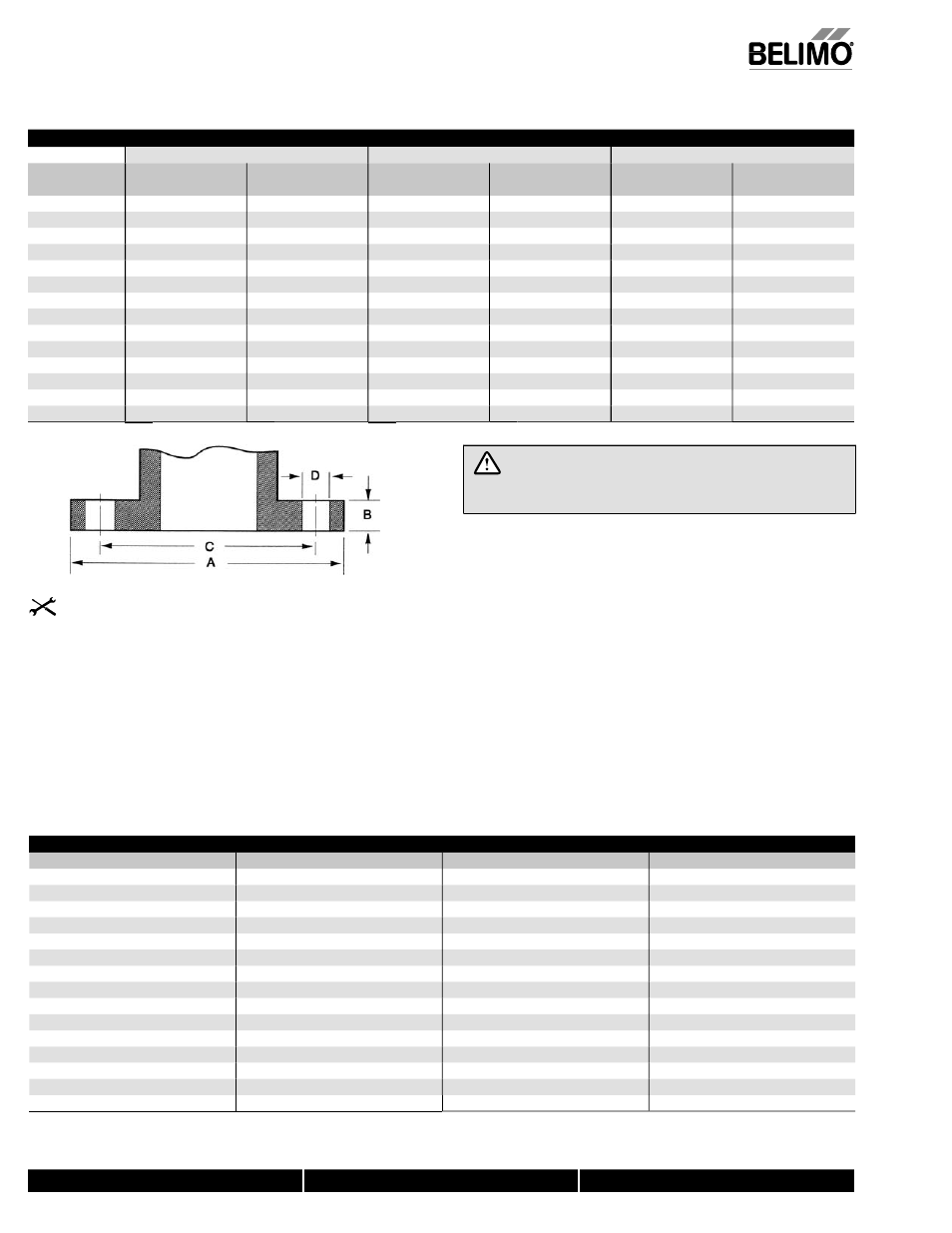

Flange Detail for ANSI B16.5 Pipe Flanges

FLANGES

DRILLING

BOLTING

Nominal

Pipe Size

A

Flange Diameter

B

Flange Thickness

C

Diameter of

Bolt Circle

D

Diameter of

Bolt Holes

Number

of Bolts

Diameter

of Bolts

2”

6”

3/4”

4-3/4”

3/4”

4

5/8”

2-1/2”

7”

7/8”

5-1/2”

3/4”

4

5/8”

3”

7-1/2”

15/16”

6”

3/4”

4

5/8”

4”

9”

15/16”

7-1/2”

3/4”

8

5/8”

5”

10”

15/16”

8-1/2”

7/8”

8

3/4”

6”

11”

1”

9-1/2”

7/8”

8

3/4”

8”

13-1/2”

1-1/8”

11-3/4”

7/8”

8

3/4”

10”

16”

1-3/16”

14-1/4”

1”

12

7/8”

12”

19”

1-1/4”

17”

1”

12

7/8”

14”

21”

1-3/8”

18-3/4”

1-1/8”

12

1”

16”

23-1/2”

1-7/16”

21-1/4”

1-1/8”

16

1”

18”

25”

1-5/8”

22-3/4”

1-1/4”

16

1-1/8”

20”

27-1/2”

1-11/16”

25”

1-1/4”

20

1-1/8”

24”

32”

1-7/8

29-1/2”

1-3/8”

20

1-1/4”

WARNING! Personal injury or property damage may result

if the valve is installed where service conditions could exceed the

valve ratings.

5. Check the fl ange bolts or studs for proper size, threading, and length.

6. These valves are designed to be installed between ASME/ANSI Class

125/150 fl anges.

7. Carefully follow installation using welded fl anges on page 82 of

this document.

8. Follow ASME fl ange alignment standards:

SECTION 335.1.1 ALIGNMENT

a. PIPING DISTORTIONS: Any distortion of piping to bring into

alignment for joint assembly which introduces a detrimental strain

in equipment or piping components is prohibited.

b. FLANGE JOINTS: Before bolting up, fl ange faces shall be aligned

to the design plane within 1/16”/ft measured across any diameter;

fl ange bolt holes shall be aligned within 1/8” maximum offset.

9. When observed during assembly, the fl ange faces shall be parallel

within 1 degree, and the force required to align pipe axes shall not

exceed 10 lb/ft per inch of NF bolts and nuts shall be fully engaged.