BUCHI Encapsulator B-395 Pro User Manual

Page 54

6 Operation

54

B-395 Pro

Operation Manual, Version C

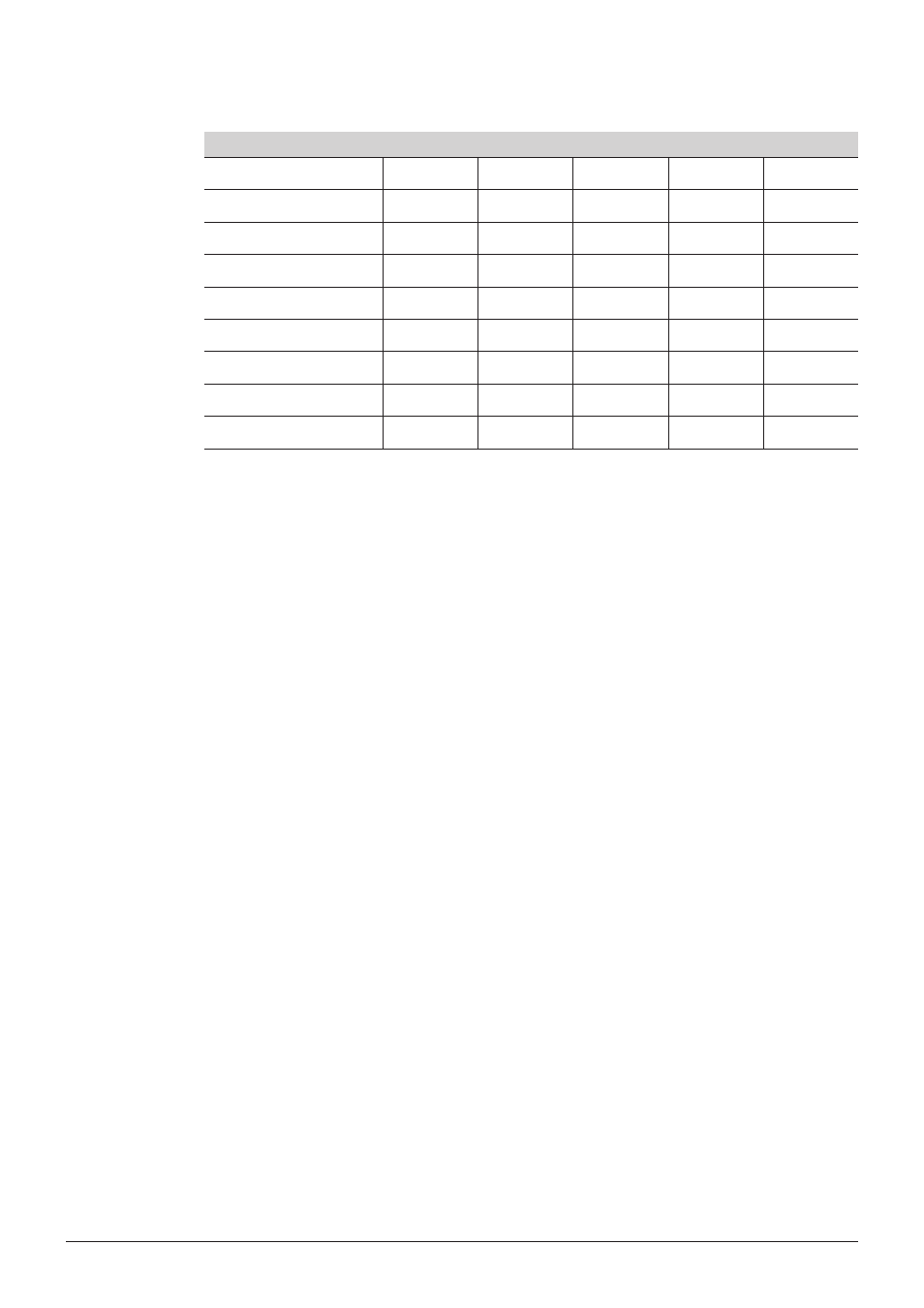

Table 6-4: Encapsulator trial test work sheet (syringe pump)

Syringe size [mL]

Nozzle size [

µm]

Alginate concentr. [%]

Pumping speed [mL/min]

Vibration frequency [Hz]

Amplitude

Approximate bead size [

µm]

Homogeneity [%]

Comments

6. Inspect the beads under a microscope with a micrometer scale eyepiece and record your obser-

vations of diameter, uniformity and shape in table 6-4.

7. Repeat this procedure for each change in process parameters.

NOTE

When producing small beads with a diameter <500 µm, it may occur that their shape is not spherical

but somewhat oval. This is mainly due to the surface tension of the polymerization solution. A very

critical point for the bead is it‘s entrance into the polymerization solution. If the surface tension is

high, then the bead is partially held back at the surface and polymerization starts before the bead can

regain a round shape. This problem can be eliminated by adding a small quantity of surfactant like

Tween 20 to the polymerization mixture.

8. Compare the influence of the electrostatic dispersion unit by collecting beads at the same vibra-

tion frequency and pumping rate with and without the electrostatic function turned on.

9. Determine the working field by stepwise changing the pumping speed from the lowest liquid flow

rate which just creates a continuous liquid jet up to a flow rate where a clear bead chain is no

longer visible at any vibration frequency. Note the corresponding lowest and highest frequencies in

table 6-5.