2 technical data, 3 materials used, Technical data – BUCHI Encapsulator B-395 Pro User Manual

Page 15: Materials used, 3 .2 technical data, 3 .3 materials used

3 Technical data

15

B-395 Pro

Operation Manual, Version C

3 .2

Technical data

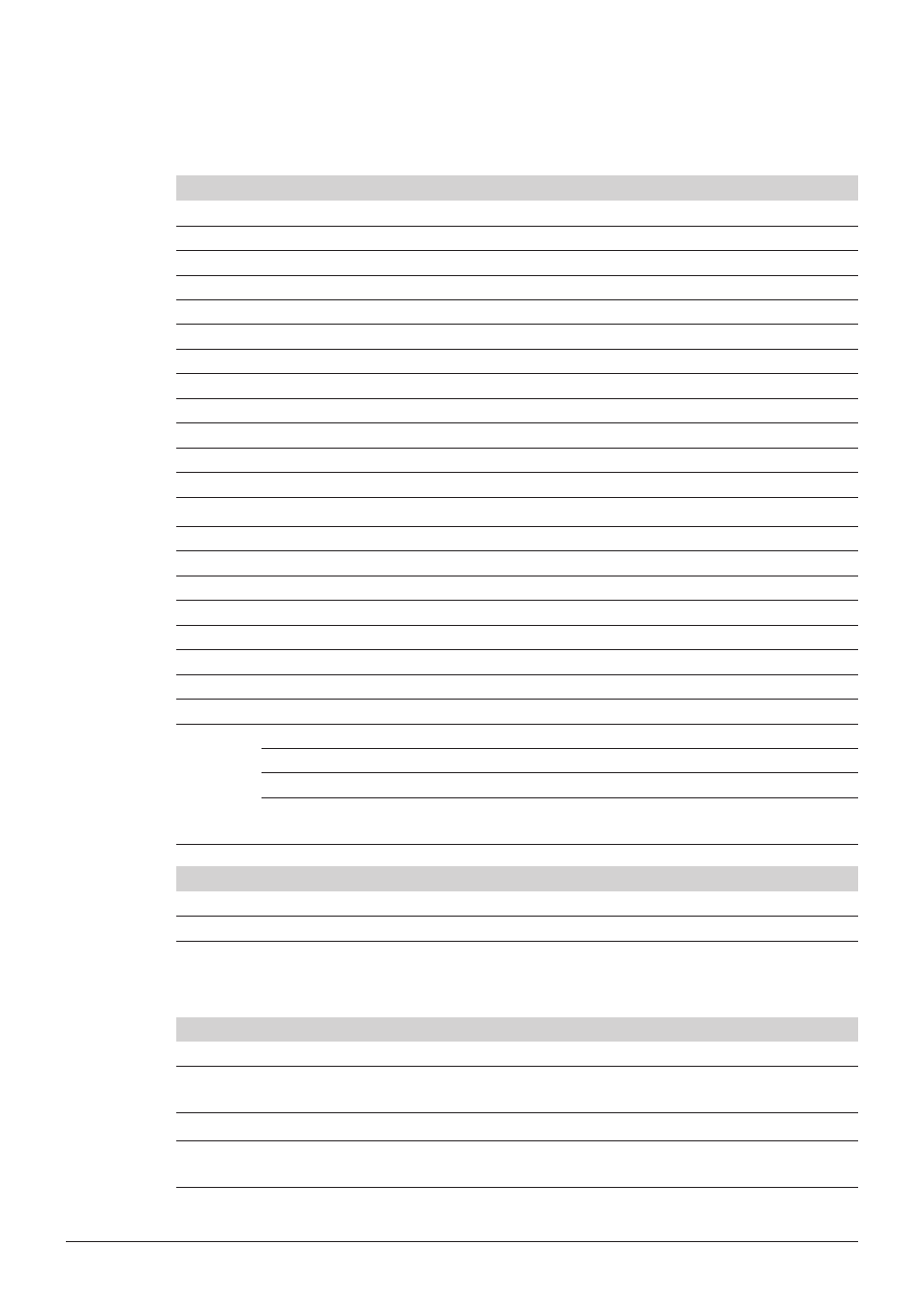

Table 3-5: Technical data Encapsulator B-395 Pro

Power consumption

max. 150 W

Connection voltage

100–240 VAC

Mains supply voltage fluctuations

up to ±10% of the nominal voltage

Frequency

50/60 Hz

Fuse

3.15 A

Dimensions (W

×H×D)

32

Ч38Ч48 cm

Weight

11

kg

Nozzle diameter of single (= core) nozzles

0.08, 0.12, 0.15, 0.20, 0.30, 0.45, 0.75 and 1.00 mm

Nozzle diameter of shell nozzles

0.20, 0.30, 0.40, 0.50, 0.60, 0.70 and 0.90 mm

Droplet size range

0.15 to 2.00 mm

Vibration frequency

40 to 6,000 Hz

Electrode tension

250 to 2,500 V

Syringe pump rate

0.01 to 50 mL/min

Pump rate by air pressure

0.5 to 200 mL/min

Maximal allowed air pressure in the system

1.5 bar

Reactor gross volume

4.5 liter

Reactor working volume

2 liter

Parts in contact with medium

autoclavable

Sterile working conditions

full

Overvoltage category

II

Pollution degree

2

Environmental conditions:

Temperature

5–40 °C

for indoor use only

Altitude

up to 2000 m

Max. relative humidity (curve parameter)

Maximum relative humidity 80 % up to 31 °C, then

decreasing linearly to 50 % relative humidity at 40 °C

Table 3-6: Material and Approvals

Material in contact with sample

stainless steel, silicone, glass, FEP, PTFE

Approvals

CE, CSA

3 .3

Materials used

Table 3-7: Materials used

Component

Material description

Reactor

Stainless steel, 3.3 boroscillate glass, FEP, PTFE

sealings: silicone, EPDM

Nozzles

Stainless steel, sealings: EPDM

Pressure bottle

Stainless steel, 3.3 boroscillate glass, FEP, PTFE

sealings: silicone, EPDM