Waterworks Ludlow Floor Mounted Exposed Tub Filler with Handshower and Metal Lever Handles User Manual

Installation guidelines

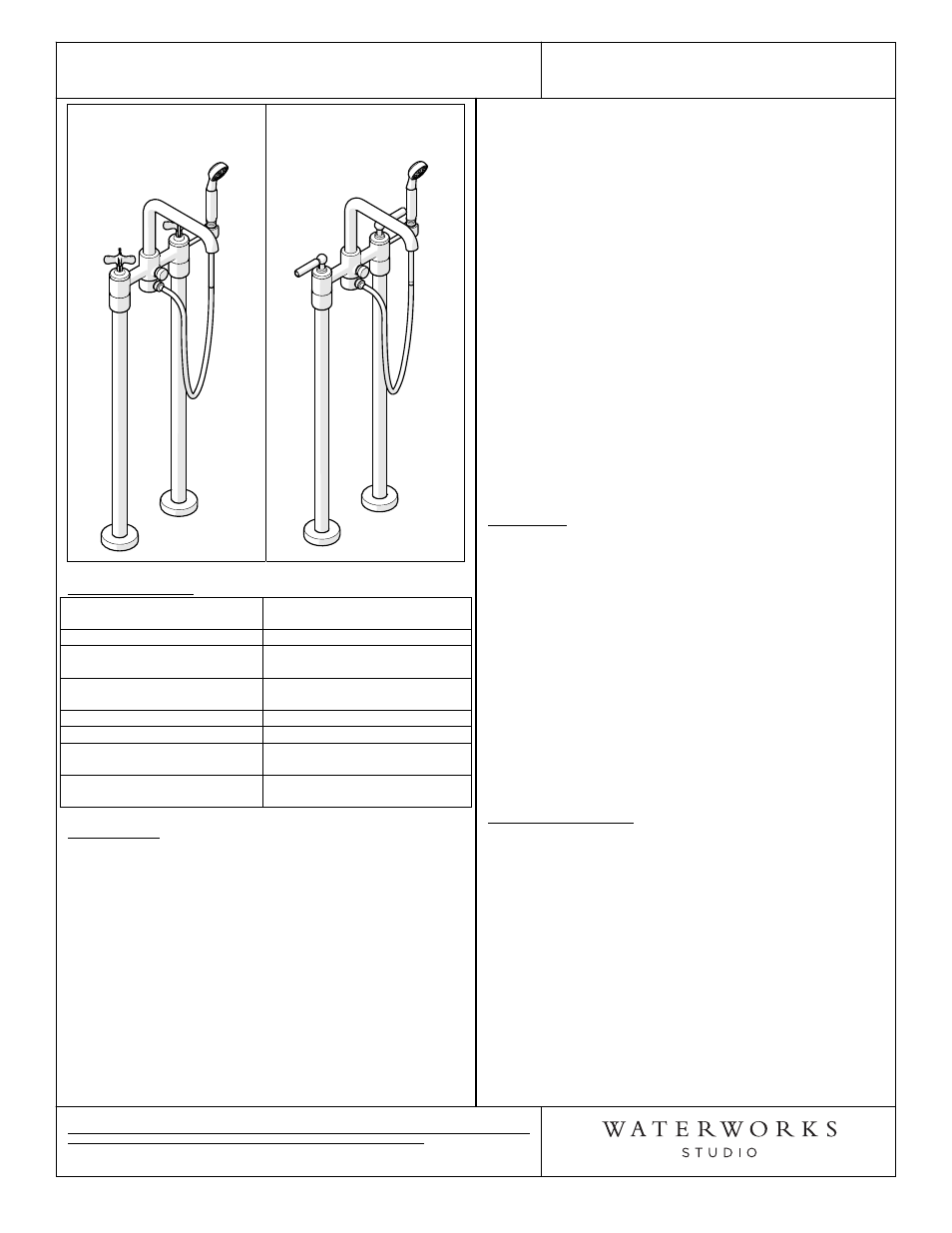

LUDLOW

Exposed Floor Mounted Tub Filler With Handshower

INSTALLATION GUIDELINES

Page 1 of 3

7.18.2014

These guidelines have been prepared for the professional contractor to aid in the installation of:

LUDLOW EXPOSED FLOOR MOUNTED TUB FILLER WITH HANDSHOWER WITH METAL CROSS

HANDLES (STYLE# LDXT60) & METAL LEVER HANDLES (STYLE# LDXT70)

All dimensions are based on original specification and are subject to change and variation.

Please consult your Design Associate for current specifications.

Metal Cross Handles

Style No. LDXT60

Metal Lever Handle

Style No. LDXT70

SPECIFICATIONS:

Handle Spread

8" [NOT ADJUSTABLE]

203 mm

Fitting Hole Diameter

Ш1-1/4" (Ш 32mm)*

Inlet/Outlet Connection

Size & Type:

3/4" Copper Sweat

(22mm Copper Sweat)

Inlet Spread

8" [NOT ADJUSTABLE]

203 mm

Spout Outlet Height

36" (914mm)

Spout Reach

8-9/16" (217mm)

Water Pressure

Recommended:

45 psi (3 Bar)

Water Pressure:

20 psi MIN - 80psi MAX

(1.4 Bar Min - 5.5 Bar Max)

IMPORTANT:

¾ To ensure this product is installed properly, you

must read and follow these guidelines.

¾ The owner/user of this product must keep this

information for future reference.

¾ Be sure your installation conforms to federal state,

and local codes. Anti-scald protection is the

responsibility of the installer and according to

applicable codes.

¾ In the State of Massachusetts, all installations must

comply with the rules and regulations set forth

within 248 CMR.

¾ This product must be installed by a professional

licensed contractor.

¾ Product should be on-site prior to rough-in. This

allows the installer to visualize the installation and

verify the inlet connection spread.

¾ Refer to the specifications and assembly drawings

attached. Product is sold partially assembled but

shown fully disassembled for illustrative and service

purposes only.

¾ Check tub measurements to assure the spout

projects far enough into the tub.

¾ Inspect this product to ensure you have all the parts

required for proper installation.

¾ Use only a strap wrench or protected/smooth-jaw

wrench on any finished surface.

¾ Run 3/4" (22mm) supply lines for maximum flow.

¾ Install accessible hot and cold service stop valves to

facilitate servicing.

ROUGH-IN:

1.

Run well supported 3/4" (22mm) hot and cold

supply lines for maximum water flow. The inlet

supply spread is 8" on-center and is not adjustable.

1-1/4" drilling for the mounting holes is

recommended.

2. Determine the location where the supplies will come

up through the floor and install a piece of 2x10 on its

side to serve as a 10" blocking surface for securing

the legs to the floor.

3. Drill 1-1/4" holes in the floor with the proper spread

for each supply to pass through.

4. Run 3/4" copper supplies up through the finished

floor and cap-off each line.

LEG INSTALLATION:

¾ Verify the 8" inlet supply spread prior to installation.

¾ See Figure 1 for Steps 5-8

5. Slide the FLOOR FLANGE over the COPPER

SUPPLY LINE and position the screw holes to the

desired location.

6. Drill 4 holes to accommodate all the SCREWS that

will be used to secure the LEG to the floor.

7. Screw the FLOOR FLANGE to the floor using the 4

FLOOR SCREWS provided, making sure flange is

level to floor.

8. Solder the COPPER SUPPLY LINES to the inner

diameter of the FLOOR FLANGE for added stability.