P30-corner-mull-layout – Oldcastle BuildingEnvelope Reliance-HTC User Manual

Page 33

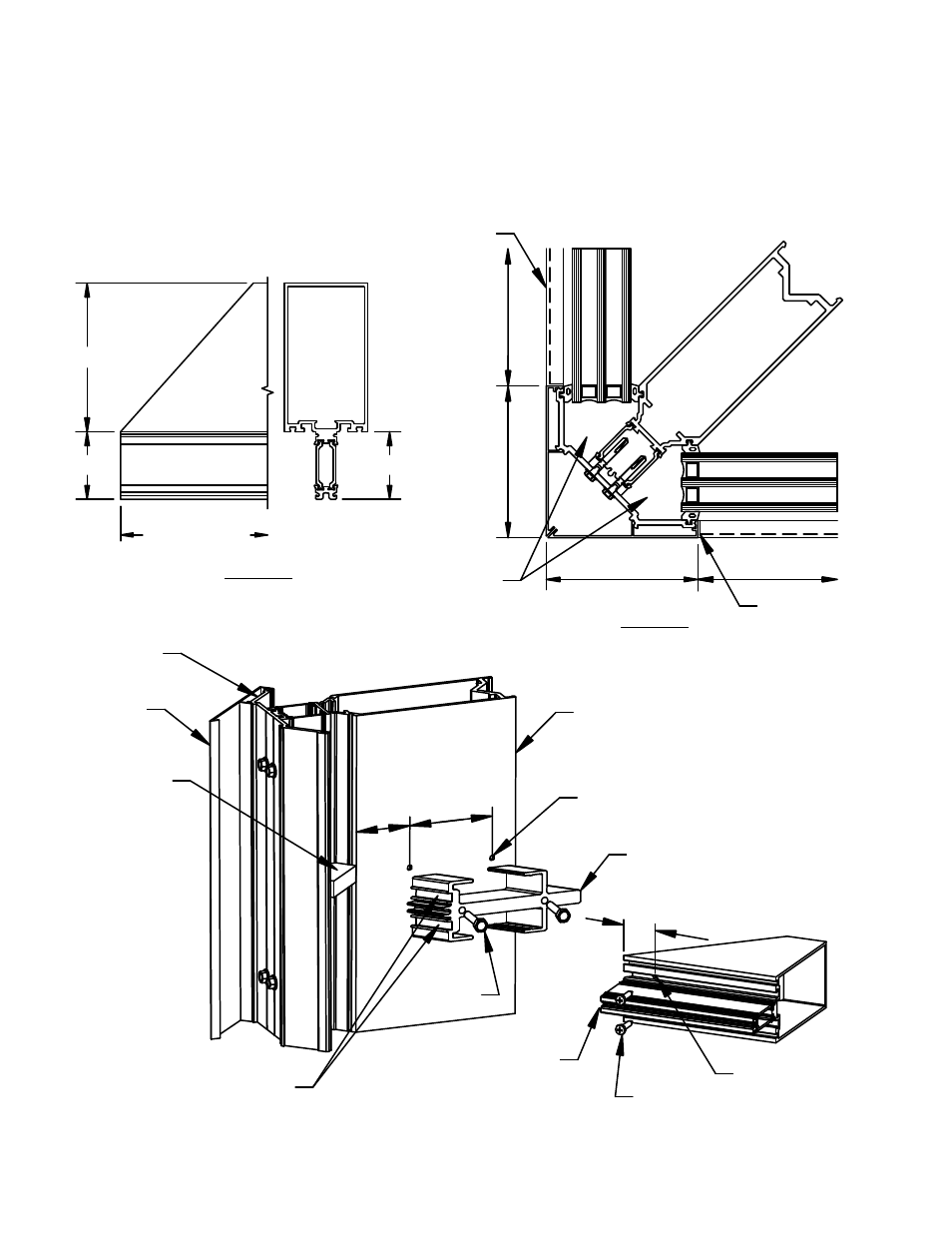

FIGURE 28 shows the basic layout of the standard one−piece corner mullion assembly. These details are for

general reference and do not necessarily reflect all conditions. For specific assembly, sealing and anchoring

notes, refer to approved shop drawings. See Parts List for specific part numbers.

Detail "A"

Miter Cut at Horizontal

(1 3/4" Glazing)

Varies

2 1/32"

Cut length = D.L.O.

(see DETAIL "B")

Detail "B"

Captured OS 90 Corner

Assembly Guide

FIGURE 28

Captured OS 90 Corner Assembly

(Cut lengths in parentheses)

2 1/32"

D.L.O.

2

1/2"

2 1/2"

D

.L

.O

.

WW-110 face cover

(DLO minus 1/16")

Zone plug

(typ. both sides)

WW-162

pressure plate

(DLO minus 1/4")

Face cover

(continuous)

Pressure plate

(continuous)

Corner mullion

#11 (.191 dia) tap hole

for #14 fastener

Match drill shear block with

5/32" dia drill for #10 screw

Corner shear block

FS-9 (2)

Straight cut at glass pocket

(Refer to DETAIL 'A' above)

FS-115 (2)

#11 (.191 dia) clear

hole for #10 screw

2 1/16" 2

5/8"

1 1/8"

Zone plug

CORNER MULLION

R E L I A N C E − H T C I N S T A L L A T I O N M A N U A L

MAY 2013

30

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com