P20-top-of-mull-seal – Oldcastle BuildingEnvelope Reliance-HTC User Manual

Page 23

3.10 After removing vertical temporary retainers, install vertical pressure plates with FS−325 screws at 9" O.C.

3.11 After removing horizontal temporary retainers, center horizontal pressure plates in opening, leaving 1/8"

gap on each end. Make sure that weep holes are on the top side of the pressure plate. When installing

NOTE: Horizontal pressure plates and face covers run continuous over SSG mullions, not to exceed 3

lites in length. SEE FIGURE 16 for splicing and sealing instructions.

3.12 After all pressure plates are installed on the frame, torque FS−325 screws to 90 in−lbs. The use of either a

drill motor with a torque limiter or torque wrench can be used. If using a cordless drill, check torque

periodically since battery usage will affect the torque setting.

3.13 Install vertical face covers. Using a wood block to protect the cover, apply with dead blow soft face

hammer. Pin the vertical face covers once per length as required, concealing pin at a horizontal location.

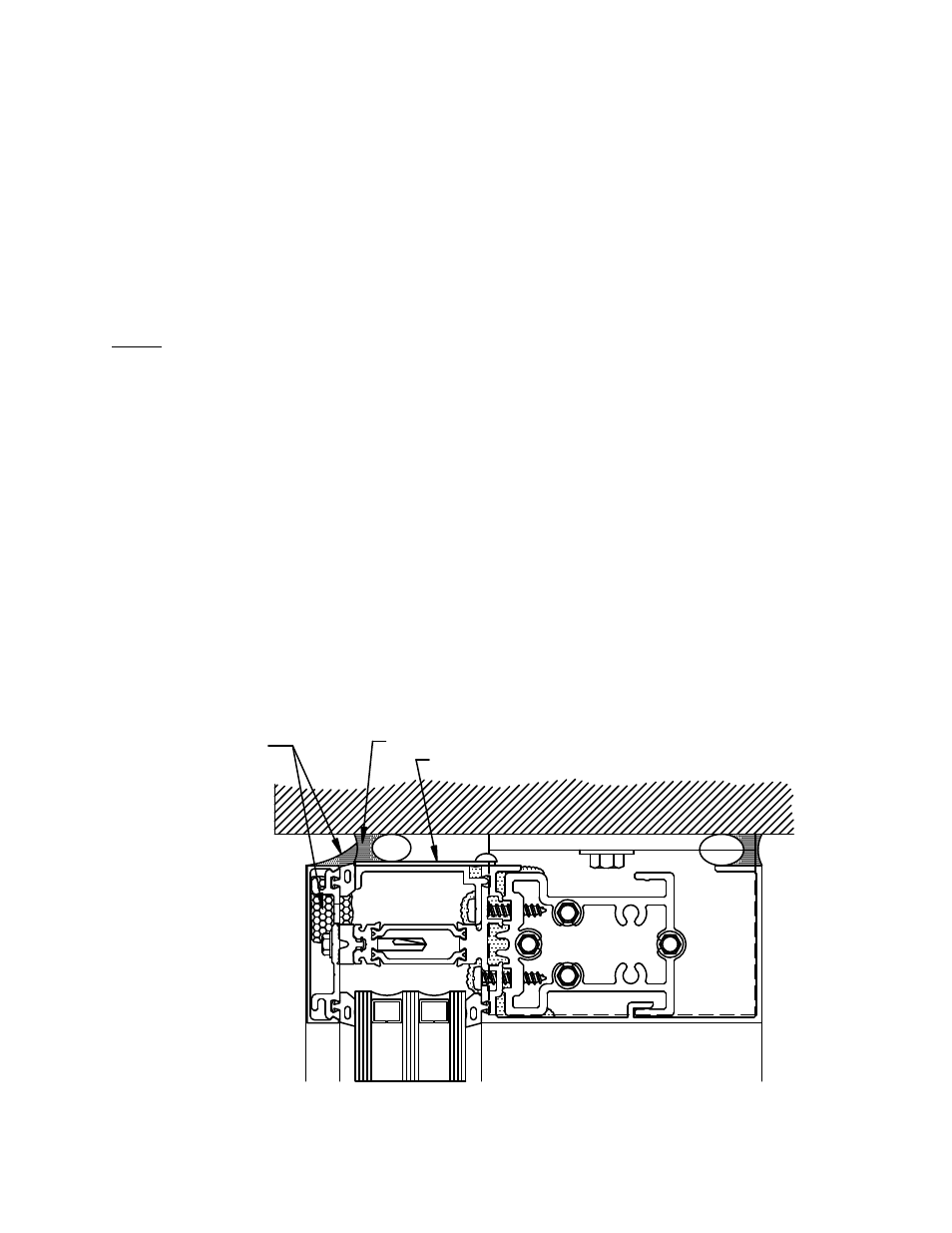

3.14 Insert backer rod into cavity at the top of each vertical mullion. Seal off end of vertical, sloping sealant

back to marry with the perimeter seal. SEE FIGURE 17.

3.15 Seal horizontal pressure plates against the vertical face covers. Tool sealant into the joint.

SEE FIGURE 18, page 12 .

3.16 Install horizontal face covers, leaving an equal gap at each end. Make sure that the weep hole in the face

cover is on the bottom.

FIGURE 17

Sealing Top of Captured Verticals

Mullion end cap

Primary perimeter seal

Backer rod inside

vertical face cover

& seal over top

GLAZING

R E L I A N C E − H T C I N S T A L L A T I O N M A N U A L

MAY 2013

20

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com

holes in pressure plates as required.

horizontal pressure plate fasteners, start at center and work to each end while pressing firmly on pressure

plate.

fasteners must be located 1 1/2˜ from horizontal/vertical mullion fasteners must be located 1−1/2" from

horizontal/vertical mullion intersections in order ot maintain proper compression on the glass. Drill 7/32"