P18-pressplt-sealing – Oldcastle BuildingEnvelope Reliance-HTC User Manual

Page 21

3.7 If required, install GP−111 (1˜, 1 3/4" & 2" infill) or GP−112 (1/4˜ infill) side blocks with silicone at centerline

of each lite of glass, along vertical edges, or per approved shop drawings. For framing that will be

subjected to seismic events, consult glass manufacturer for preferred location. NOTE: Side blocks are

not required at SSG mullions.

3.8 Repeat steps 3.3 through 3.7 until all glass is set, working row by row up the elevation.

For elevations requiring vertical mullion splices, refer to the VERTICAL SPLICING section, pages 13 &

14, before continuing the installation.

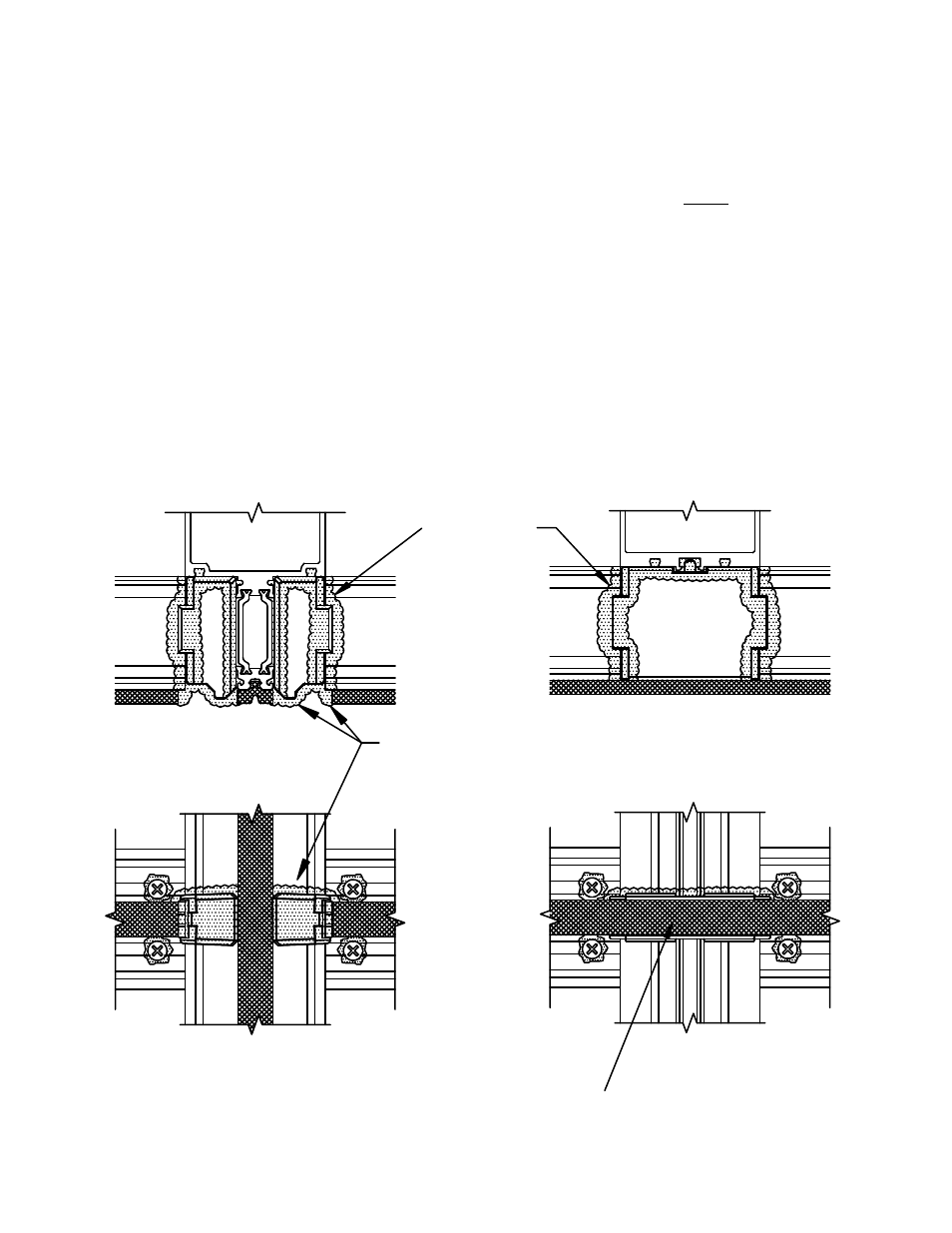

3.9 Prior to installing vertical pressure plates, apply sealant to the face of each horizontal zone plug. SEE

FIGURE 15. Vertical pressure plates must be installed before the horizontal pressure plates are applied.

Existing seal

Captured Vertical

SSG Vertical

Run thermal isolator continuous

over bridge at SSG mullion (no

special sealing required)

Note:

Just prior to installing vertical pressure plates,

fill gap between zone plug and spacer; apply

sealant to face of zone plugs.

FIGURE 15

Sealing for Pressure Plates

GLAZING

R E L I A N C E − H T C I N S T A L L A T I O N M A N U A L

MAY 2013

18

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com