P08-horizontal-fabrication – Oldcastle BuildingEnvelope Reliance-HTC User Manual

Page 11

1.6 Drill 5/16˜ diameter weep holes at 1/4 points in the horizontal pressure plate. Drill (1) 5/16˜ diameter weep hole

at the bottom of each horizontal face cover at centerline of D.L.O. SEE FIGURE 18, page 12. NOTE: For SSG

applications, face covers typically run across mullions, so there will be multiple holes in each horizontal

face cover.

1.7 All pressure plates have factory−punched holes for screws at 9˜ O.C. To ensure proper pressure on the glazing,

7/32˜ diameter holes may need to be drilled at the ends of each pressure plate as required. Locate at 1 ½˜

maximum from the ends

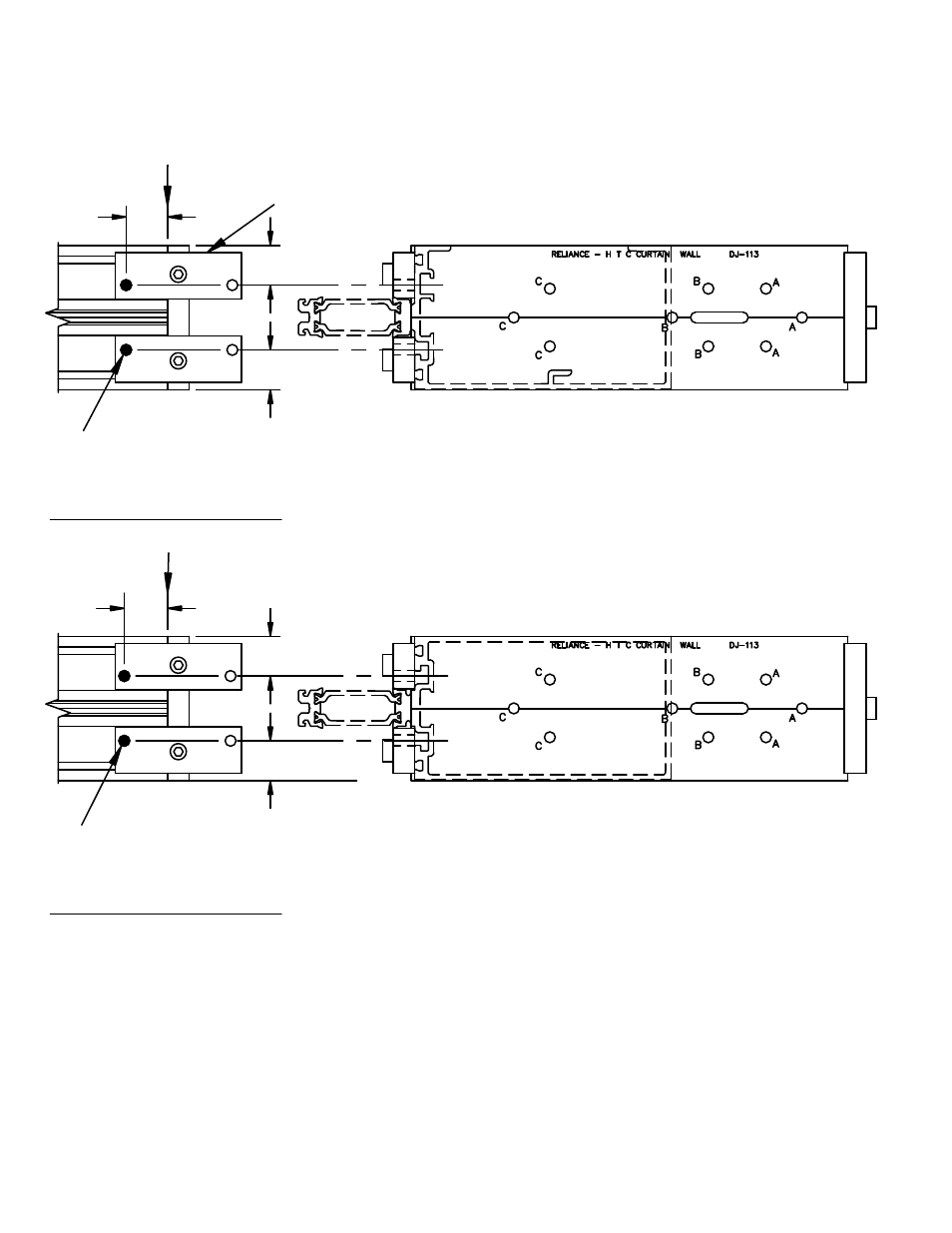

11/16"

11/16"

3/4"

Drill #11 (.191 dia) clear hole

for #10 fastener

(2 each end of member)

11/16"

11/16"

DJ−113 drill jig

23/32"

Side View of Drill Jig to Prep

Side View of Drill Jig to Prep

HOR

IZ

ONT

AL

HEAD/S

ILL

/

RO

LL−O

VE

R

23/3

2"

3/4"

HORIZONTAL

HEAD/SILL/

ROLL−OVER

23/32"

3/4"

End of horizontal

End of horizontal

Intermediate Horizontals

Head & Sill Horizontals

Drill #11 (.191 dia) clear hole

for #10 fastener

(2 each end of member)

Front View of Horizontal at End

Front View of Horizontal at End

FIGURE 3

Horizontal Fabrication

FRAME FABRICATION

R E L I A N C E − H T C I N S T A L L A T I O N M A N U A L

MAY 2013

8

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com