P16thermal-isolator-install – Oldcastle BuildingEnvelope Reliance-HTC User Manual

Page 19

3.3 Note: To avoid silicone curing before glass is set in place and contamination from job−site debris,

glazing prep must be done as each opening is glazed. Do not pre−seal the gaskets in the entire

frame; seal only the gaskets in the opening for which you are ready to set glass.

· Install interior gaskets into back member (vertical gaskets first). If mullion is spliced, run gasket

through the splice joint, setting in fresh silicone at the joint. Trim the gasket dart as required to form an

air tight seal. (Glazing gaskets at verticals run through; horizontal gaskets butt into the vertical

gaskets.

· Crowd gaskets into corners, cutting horizontal gaskets at a slight angle to conform to the bevel on

vertical gaskets.

· Pulling the horizontal gasket back at the ends, seal joint at gasket corners JUST PRIOR TO GLAZING

THE OPENING. Release the gasket back to its original position, making sure sealant fills entire joint.

· Tool corner joints after glass is set and temporary glazing retainers are in place.

NOTE: Sealant is not required at the horizontal gasket abutting an SSG mullion. This gap will be

sealed during application of structural silicone.

3.4 Position setting blocks at correct location (two per lite). Refer to approved shop drawings or deadload

charts. Lubricating the top of setting blocks will help insure proper setting of glass. Note: Consult glass

manufacturer for correct setting block location and length for glass sizes in excess of 40 sq.ft.

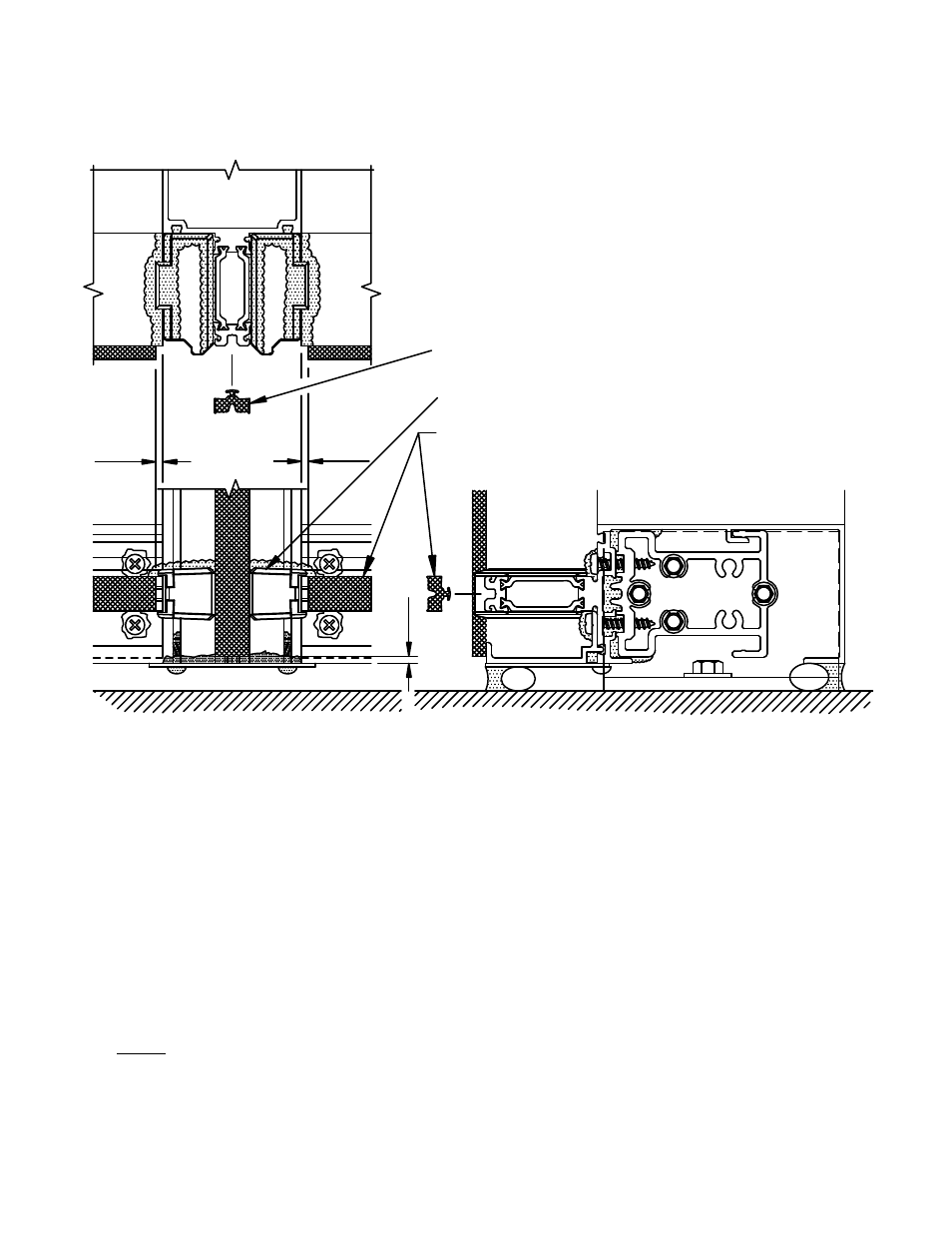

1/8"

1/

8"

1/8"

Thermal isolator

(not required at SSG mullion)

Zone plug

FIGURE 12

Thermal Isolator Installation

Thermal isolator

GLAZING

R E L I A N C E − H T C I N S T A L L A T I O N M A N U A L

MAY 2013

16

Phone: 1-866-OLDCASTLE (653-2278)

Web Address: www.oldcastlebe.com