Replacing defective processor module, Installation – Carrier 040-420 User Manual

Page 73

4

OUT

S W I T C H

M O D U L E

_

_

_

AND ASSOCIATED MODULAR UNITS

-

-

-

-

2

FLOTRONIC’” II UNITS

T B

Terminal Block

NOTE: The

Flotronic II units require the acces-

sory options module for this feature

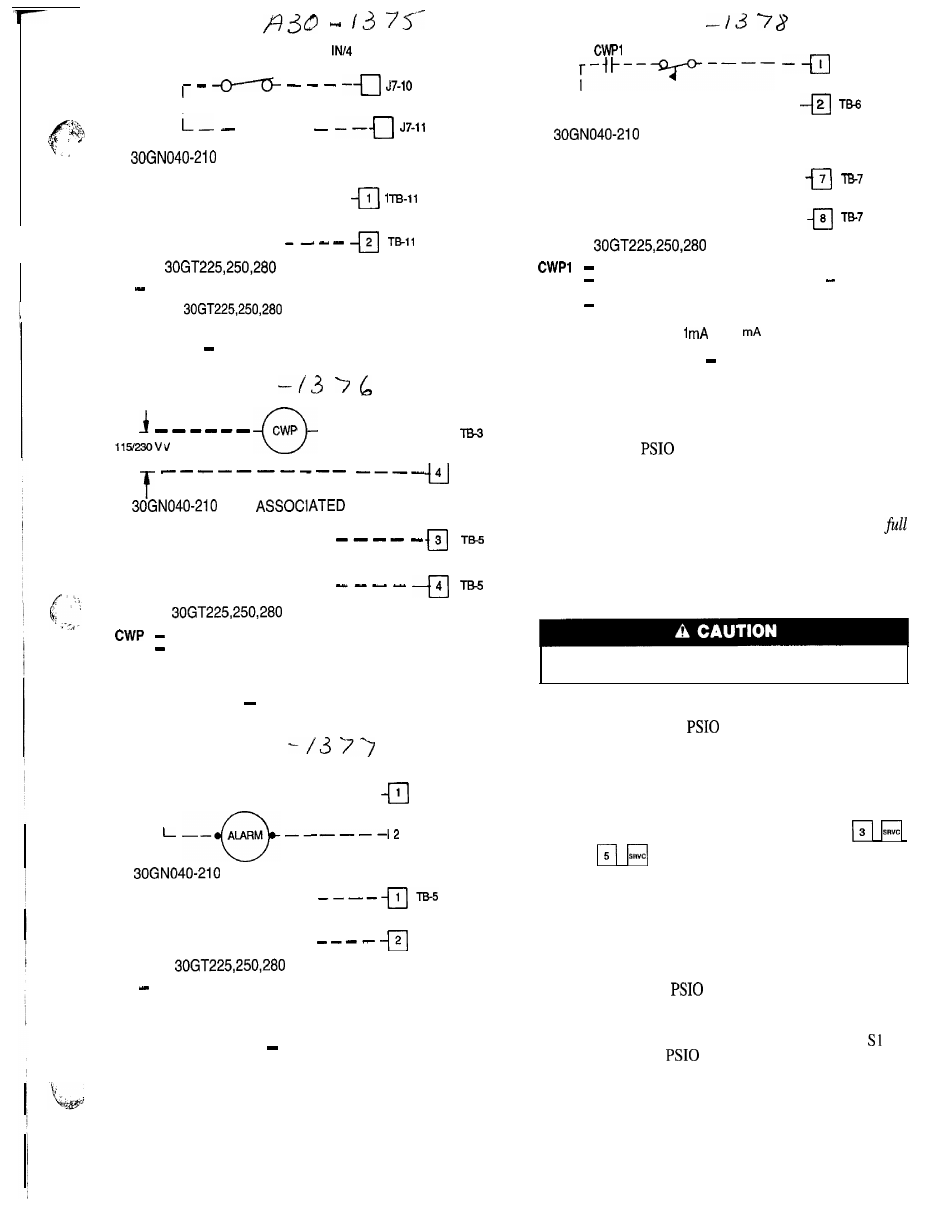

Fig. 33

Remote Dual Set Point Control

-

-

-

-

-

- c l

3

4

T5-3

AND

MODULAR UNITS

3

4

FLOTRONIC II UNITS

Chilled Water Pump

T B

Terminal Block

NOTE: The maximum load allowed for the chilled water pump circuit

is 125 va sealed, 1250 va inrush at 115 or 230 v

Fig. 34

Chilled Water Pump

ALARM SHUTOFF

S W I T C H

I -

-

-

-

-

-

-

-

a

-

-

-

1 TB-3

I

i

T 8 - 3

c

l

AND ASSOCIATED MODULAR UNITS

2 TB-5

FLOTRONIC II UNITS

TB

T e r m i n a l B l o c k

NOTE: The maximum load allowed for the alarm circuit is 125 va

sealed, 1250 va inrush at 115 or 230 v

Fig. 35

Remote Alarm

7 3

(CWFS)

TB-6

I - -

-

-

-

-

- -

-

- -

-

-

AND ASSOCIATED MODULAR UNITS

- - - - -

7

-

-

-

-

-

8

FLOTRONIC I I UN ITS

Chilled Water Pump Interlock

CWFS

Chilled Water Flow Switch (not required low flow

protection is provided by Flotronic II controls)

T B

Terminal Block

NOTE: Contacts must be rated for dry circuit application, capable of

reliably switching a 5 vdc,

to 20

load.

Fig. 36

Interlocks

REPLACING DEFECTIVE

PROCESSOR MODULE

The replacement part number is printed on a small label

on front of the

module. The model and serial num-

bers are printed on the unit nameplate located on an exte-

rior corner post. The proper software and unit configuration

data is factory installed by Carrier in the replacement mod-

ule. Therefore, when ordering a replacement processor mod-

ule (PSIO), specify complete replacement part number,

unit model number, and serial number. If these numbers

are not provided, the replacement module order is config-

ured instead as a generic Flotronic’” 11 replacement mod-

ule. This requires reconfiguration of the module by the

installer.

Electrical shock can cause personal injury, Disconnect

all electrical power before servicing.

Installation

1.

2.

3 .

4 .

5 .

6 .

7 .

Verify the existing

module is defective by using

the procedure described in the Control Modules sec-

tion on page 64.

Refer to Start-Up Checklist for Flotronic II Chiller Sys-

tems (completed at time of original start-up) found in

job folder. This information is needed later in this

procedure. If checklist does not exist, fill out the

and

configuration code sections on a new check-

list. Tailor the various options and configurations as

needed for this particular installation.

Check that all power to unit is off. Carefully discon-

nect all wires from defective module by unplugging the

6 connectors. It is not necessary to remove any of the

individual wires from the connectors. Remove the green

ground wire.

Remove defective

by removing its mounting screws

with a Phillips screwdriver, and removing the module

from the control box, Save the screws for later use.

Use a small screwdriver to set address switches and

S2 on the new

module to exactly match the set-

tings on the defective module.

Package the defective module in the carton of the new

module for return to Carrier.

Mount the new module in the unit control box using a

Phillips screwdriver and the screws saved in Step 4 above.