Carrier 040-420 User Manual

Page 4

In the LOCAL/ENABLE position, the chiller is under lo-

cal control and responds to the scheduling configuration and

set point data input at its own local interface device (key-

pad and display module).

In the CCN position, the chiller is under remote control

and responds only to CCN network commands. The occupied/

unoccupied conditions are defined by the network. All key-

pad and display functions can be read at the chiller regard-

less of position of the switch.

CCN run or

stop

condition is established by a command

from the CCN network. It is not possible to force outputs

from the CCN network, except that an emergency stop com-

mand shuts down the chiller immediately and causes

52” to be displayed.

Table 2

LOCAL/ENABLE-STOP-CCN

Switch Positions and Operation

S W I T C H

P O S I T I O N

STOP

LOCAL/ENABLE

U N I T

CONFIGURATION AND

OPERATION

SET POINT CONTROL

Keypad Control CCN Control

Unit Cannot Run Read/Write

Read Only

Unit Can Run

Read/Limited Write Read

Unit Cannot Run Read Only

Unit Can Run

R e a d O n l v

Read/Limited Write

Electronic Expansion Valve (EXV)

The micro-

processor controls the EXV through the EXV driver mod-

ule. Inside the expansion valve is a linear actuator stepper

motor.

The lead compressor in each circuit has a thermistor and

a pressure transducer located in the suction manifold after

the compressor motor. The thermistor measures the tem-

perature of the superheated gas entering the compressor cyl-

inders. The pressure transducer measures the refrigerant

pressure in the suction manifold. The microprocessor con-

verts the pressure reading to a saturated temperature. The

difference between the temperature of the superheated gas

and the saturation temperature is the superheat. The micro-

processor controls the position of the electronic expansion

valve stepper motor to maintain 29 F (16 C) superheat.

At initial unit start-up, the EXV position is at zero. After

that, the microprocessor keeps accurate track of the valve

position in order to use this information as input for the

other control functions. The control monitors the superheat

and the rate of change of superheat to control the position

of the valve. The valve stroke is very large, which results

in very accurate control of the superheat.

Sensors

The Flotronic

II chiller control system gath-

ers information from sensors to control the operation of the

chiller. The units

use

6 standard pressure transducers and

4 standard thermistors to monitor

pressures and tem-

peratures at various points within the chiller. Sensors are

listed in Table 3.

Table 3

Thermistor and Transducer Locations

Sensor

Sensor

D P T - A

S P T - A

O P T - A

S P T - B

O P T - B

THERMISTORS

Location

Cooler Leaving Water Temp

Cooler Entering Water Temp

Compressor Suction Gas Temp Circuit A

Compressor Suction Gas Temp Circuit B

Remote Temperature Sensor (Accessory)

Location

Compressor Al Discharge Pressure

Compressor Al Suction-Pressure

Compressor Al Oil Pressure

Compressor Bl Discharge Pressure

Compressor

Suction Pressure

Compressor

Oil Pressure

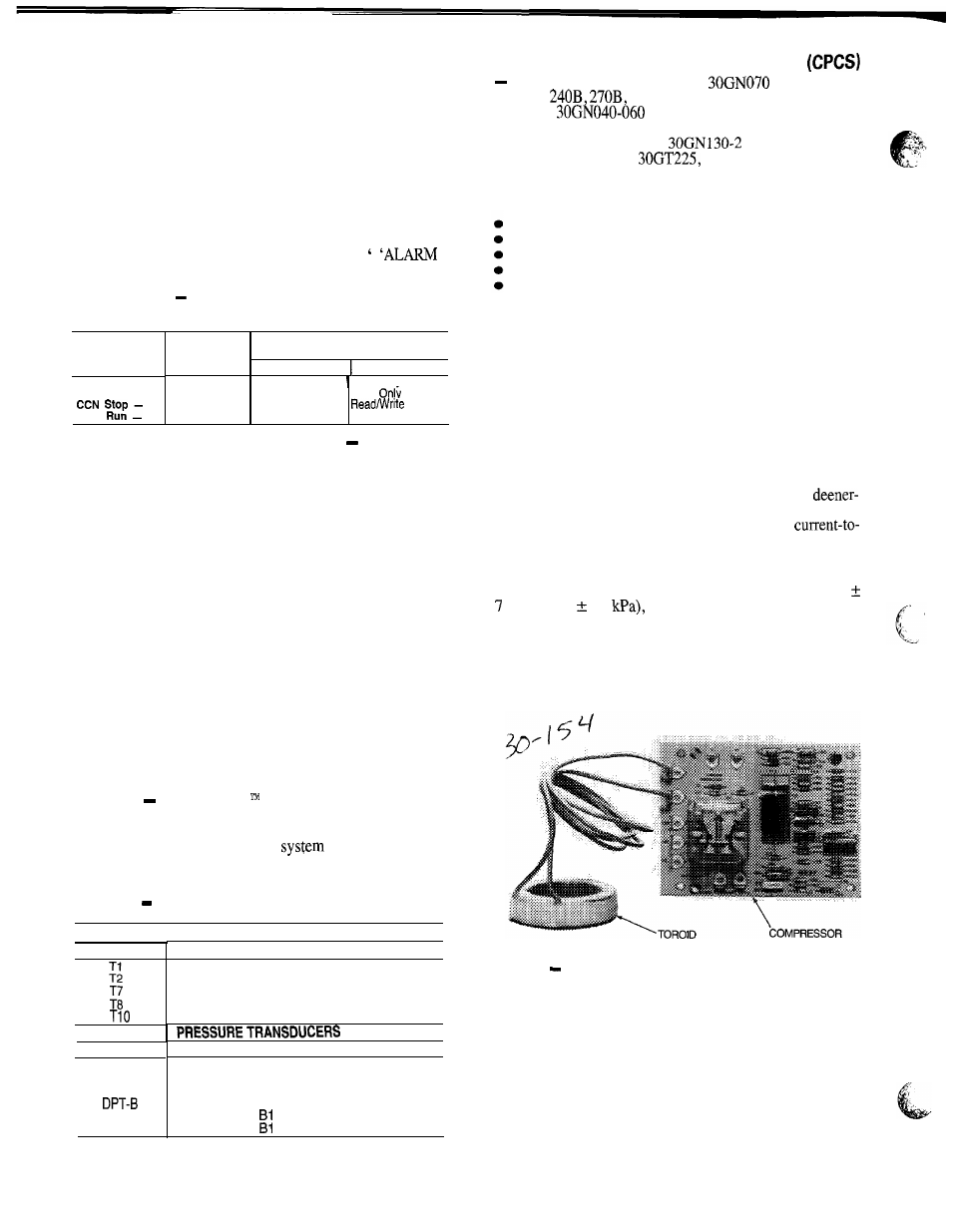

Compressor Protection Control Module

Each compressor on models

(50 Hz), 080-

100, and

has its own CPCS as standard equip-

ment. All

and 070 (60 Hz) units feature the

CPCS as an accessory, and CR (control relay) as standard

equipment. See Fig. 2. The

10 and associated

modular units and the

250, and 280 Flotronic II

units have a CR as standard equipment. The CPCS or CR is

used to control and protect the compressors and crankcase

heaters. The CPCS provides the following functions:

compressor contactor control

crankcase heater control

compressor ground current protection

status communication to processor board

high-pressure protection

The CR provides all of the same functions as the CPCS

with the exception of compressor ground current protec-

tion. Ground current protection is accomplished by using a

CGF (compressor ground fault) board in conjunction with

the CR. The CGF provides the same ground fault function

as the CPCS for units where the CPCS is not utilized.

One large relay is located on the CPCS board. This relay

(or CR) controls the crankcase heater and compressor

contactor. The CPCS also provides a set of signal contacts

that the microprocessor monitors to determine the operating

status of the compressor. If the processor board determines

that the compressor is not operating properly through the

signal contacts, it will lock the compressor off by

gizing the proper 24-v control relay on the relay board. The

CPCS board contains logic that can detect if the

ground of any compressor winding exceeds 2.5 amps. If

this condition occurs, the CPCS module shuts down the

compressor.

A high-pressure switch with a trip pressure of 426

psig (2936 48

is wired in series with the CPCS.

If this switch opens during operation, the compressor stops

and the failure is detected by the processor when the signal

contacts open. The compressor is locked off. If the lead

compressor in either circuit is shut down by the high pres-

sure switch or ground current protector, all compressors in

the circuit are locked off.

PROTECTION BOARD

Fig. 2

Compressor Protection Control Module

4