Carrier 040-420 User Manual

Page 39

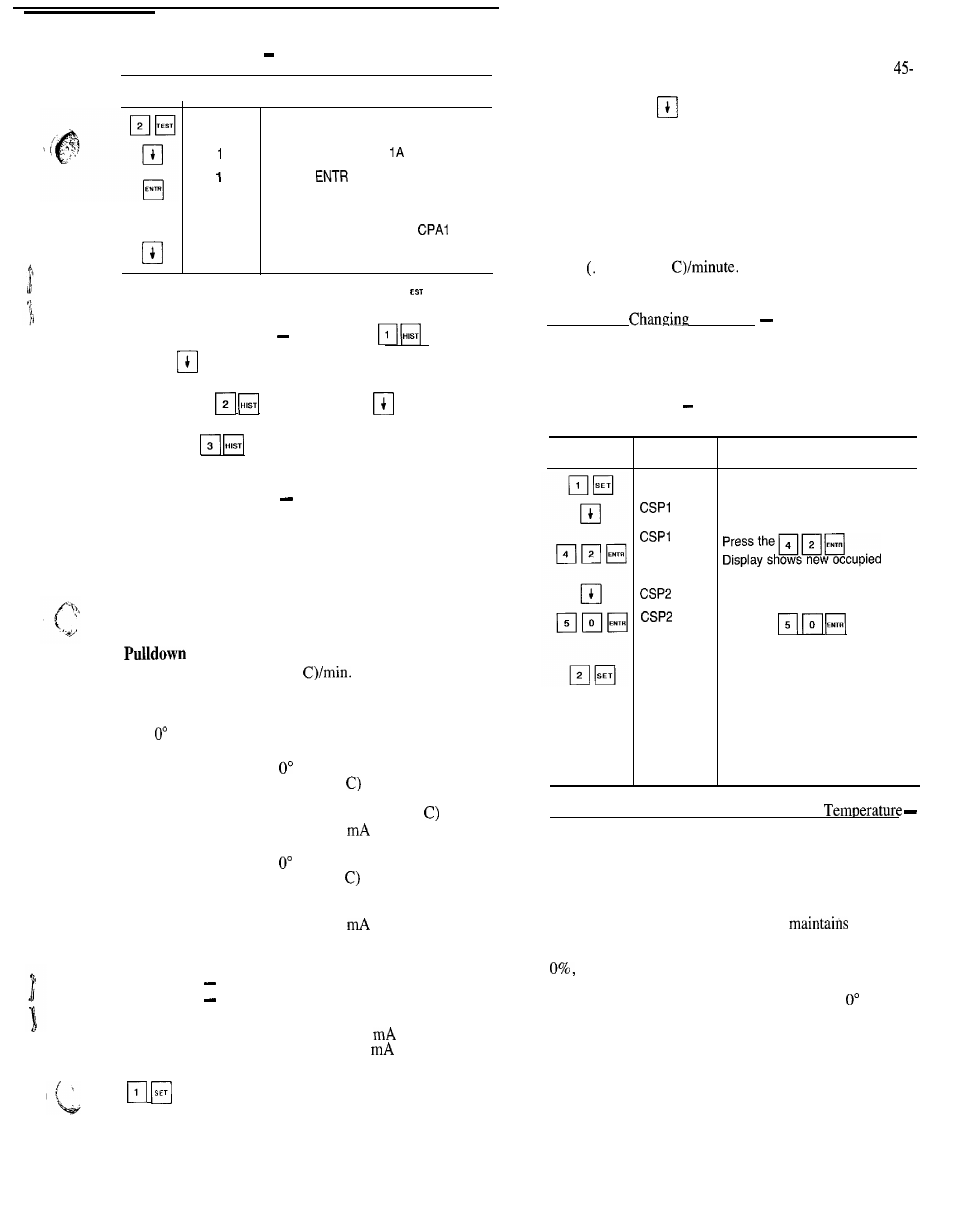

Example 3

Using Test Function

KEYPAD DISPLAY

I

ENTRY

RESPONSE

COMMENTS

C O M P

CPA OFF

CPA ON

CPA 1 OFF

CPA 2 OFF

Factory/field test of compressors

subfunction of test function

Circuit A, Compressor

test

Pressing

starts the test:

when the compressor should be running

the display shows CPA1 on

If the test is allowed to time out (10 sec-

onds) the display will show

off

Pressing the down arrow key advances

the system to Circuit A, compressor 2 test

NOTE: Once a compressor has been run using the

function, it

is not allowed to run again for 30 seconds.

E l

HISTORY FUNCTION

Keystrokes

and sub-

sequent

keystrokes display total unit run time and total

run time for each circuit.

.

Keystrokes

and subsequent

keystrokes dis-

play total unit starts and the total starts for each circuit.

Keystrokes

and subsequent

q

keystrokes dis-

play the last 5 alarms along with a description of each alarm.

SET POINT FUNCTION Set points are entered through

the keypad. Set points can be changed within the upper and

lower limits, which are fixed. The ranges are listed

below.

Chilled Water Set Point

Water:

38 to 70 F (3.3 to 21 C)

Brine:

15 to 70 F (-9.4 to 21 C)

Set Point

0.2 to 2.0 F (0.11 to 1.1

Reset Set Points

Maximum Reset Range:

to 20” F (0” to 11” C)

Maximum Reset Reference Range:

Return Fluid Reset to 20” F

(0” to 11”

External Temperature Reset 20 to 125 F

(-6.6 to 51.6

External Signal Reset 4 to 20

Minimum Reset Reference Range:

Return Fluid Reset to 20” F

(0” to 11”

External Temperature Reset 20 to 125 F

(-6.6 to 51.6 C)

External Signal Reset 4 to 20

Demand Limit Set Points

Switch Input:

Step 1

0 to 100% Capacity Reduction

Step 2

0 to 100% Capacity Reduction

External Signal:

Maximum Demand Limit 4 to 20

Minimum Demand Limit 4 to 20

Set points are grouped in subfunctions as follows:

Displays chiller water and cooling ramp set points.

a. The first value shown is the occupied chilled water

set

point.

b. The next value displayed depends on how the sched-

ule function has been programmed. (See pages

47.) If dual set point has been selected, the next set

point after

has been pressed is the unoccupied

chilled water set point. If single

set

point or inactive

schedule has been selected in the schedule function,

then when

q

is pressed, the display shows the

modified chilled water set point.

c. The final value displayed when the

q

is pressed

is the cooling ramp loading rate. This is the maxi-

mum rate at which the leaving chilled water is al-

lowed to drop, and can be field set from 0.2 to 2.0 F

11” to 1.1”

This value is not displayed

unless the function is enabled (see Adjustable Field

Configurations on page 45).

Reading and

Set Points Example 4 shows how

to read and change the chilled water set point. Other set

points can be changed by following the same procedure.

Refer to Table 9 for the sequence of display of set points in

each subfunction.

Example 4

Reading

and

Changing

Chilled Water Set Point

KEYPAD

E N T R Y

DISPLAY

RESPONSE

S E T P O I N T

44.0

420

44.0

50.0

R E S E T

C O M M E N T S

System set points

Present occupied chilled water

set point is 44 0 F

chilled water set point is 42 0 F

P r e s e n t u n o c c u p i e d c h i l l e d w a t e r

set point is 44.0 F

Press the

D

i

s

p

l

a

y

shows new unoccupied chilled

water set point is 50.0 F

Displays the maximum reset and

minimum reset set points The

minimum and maximum reference

reset set points can also be

displayed.

These set points are not

accessible when reset type has

been configured for NONE in

the service function

Temperature Reset Based on Return Water

The control system is capable of providing leaving water

temperature reset based on return water temperature. Be-

cause the temperature difference between leaving water tem-

perature and return water temperature is a measure of the

building load, return water temperature reset is essentially

an average building load reset method.

Under normal operation, the chiller

a constant

leaving water temperature approximately equal to chilled

water set point. As building load drops from 100% down to

entering cooler water temperature drops in proportion

to load. Thus, temperature drop across the cooler drops from

a typical 10 F (5.5 C) at full load to a theoretical F (0” C)

at no load. See Fig. 4.

At partial load, leaving chilled water temperature may be

lower than required. If this is allowed to increase (reset),

the efficiency of the chiller increases. Amount of reset can

be defined as a function of cooler temperature drop, as shown

in Fig. 4. This is a simple linear function that requires 4

pieces of input data for the set function:

39