Carrier 040-420 User Manual

Page 70

130 (50 Hz), 150-210, 225, 250, AND 280 UNITS (and

associated modular units)

Install control wiring. The minimum wire size for

stallation is 16

(American Wire Gage). Refer to

Fig. 24 and 25 for proper wiring. Open the control box

door. Locate unloader relays A and B (URA, URB) in

place of the hot gas bypass relays as shown on the com-

ponent arrangement diagram on the unit. Mount the re-

lays with the field-supplied screws. Be careful not to

damage the components and wiring in the area when mount-

ing the relays.

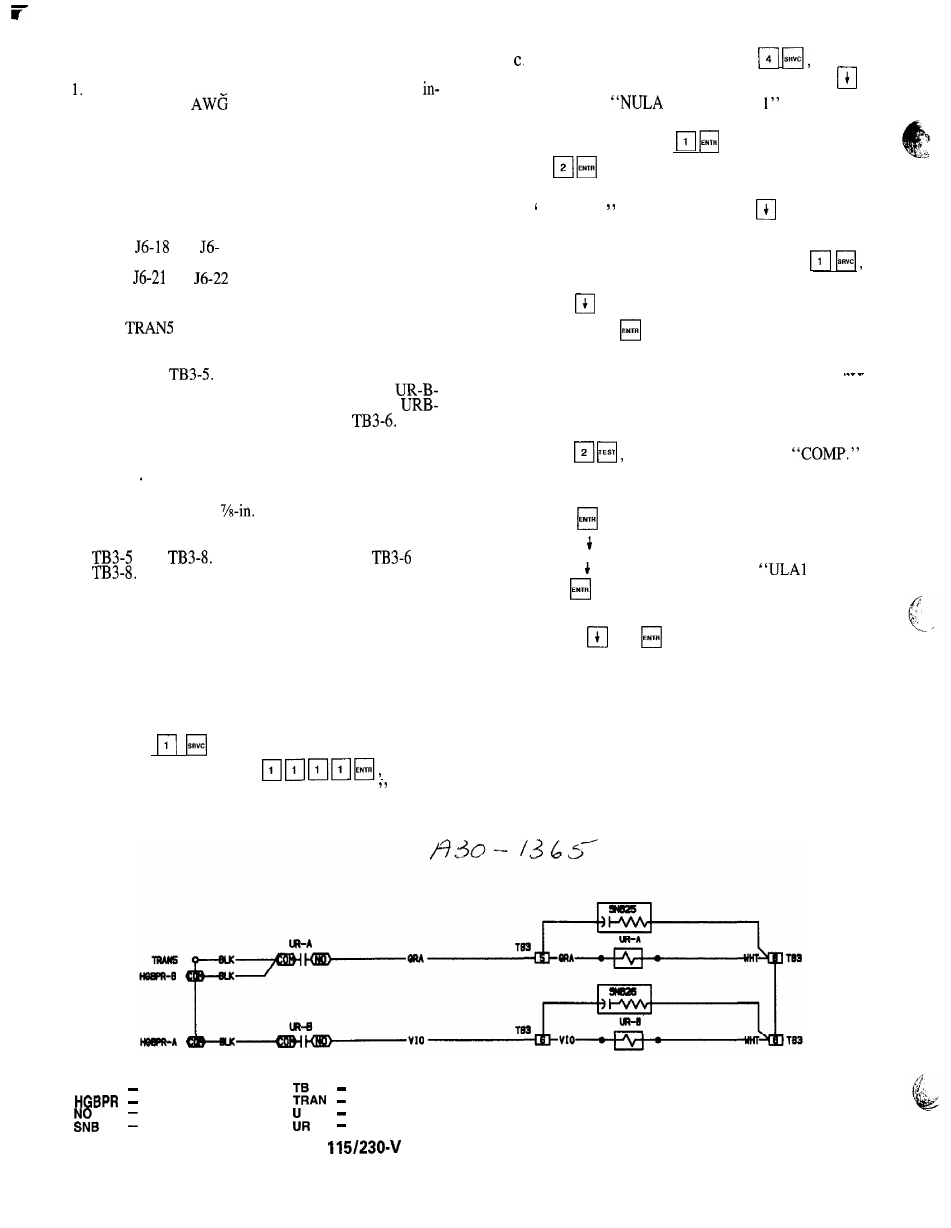

Wire the control side. Wire the URA coil in series be-

tween

and

19 of the 4 IN/4 OUT module with

the wires provided. Wire the URB coil in series be-

tween

and

of the same module with the wires

provided.

2

Locate the black wire in the control harness originating

from

labeled HGBPR-A-COM. Connect this wire

to the URA terminal COM. Connect the wire labeled

HGBPR-A-NO to URA-NO. Connect the wire from

URA-NO to

For an extra unloader on circuit

B,

connect the wire labeled HGBPR-B-COM to

COM, and the wire labeled HGBPR-B-NO to

NO. Connect the wire from URB-NO to

3. Wire in the solenoid valves.

NOTE: Wires external to the control box must be run in

conduit

Terminal blocks are provided for easy field wiring. Use

one of the isolated

(22-mm) holes in the side of

the compressor electrical box with a strain relief to run

the wires to the solenoid coil. Connect URA between

and

Connect URB between

and

Check all of the electrical connections for proper

location and tightness, and replace and secure the elec-

trical box of the compressor,

4. Configure the microprocessor, Once the relays are mounted

in the control box, the microprocessor must be config-

ured for the unloader option. ‘To do so:

a. Be sure the LOCAL/ENABLE-STOP-CCN switch is

in the STOP position.

b. Log into the processor and enter the service func-

t i o n u s i n g t h e k e y p a d a n d d i s p l a y m o d u l e .

Type

. The keypad LCD will display

“PASSWORD.” Enter

and the

keypad LCD will display “LOGGEDON.

COM

5

d.

To change the configuration, type

and the

keypad LCD will display “FLD CFG.” Press

until either

0” or “NULA

is displayed

(depending on the number of unloaders provided as

standard), Then press

(for 1 unloader on Al)

or

(for 2 unloaders on compressor Al). The

display will now read either “NULA 1” or

‘NULA 2, as appropriate, Press

to get to the

NULB display, and change this setting in the same

manner as with circuit A.

Once the configuration is complete, press

and the keypad LCD will display “LOGGEDON,”

Press

until the keypad LCD display reads “LOG

OFF.” Press

and the keypad LCD will display

“EXIT LOG.”

Once the unloader heads are installed, the unit is checked

for leaks, and the system is prepared for operation per

the instructions for the compressor unloader head instal-

lation, check the output of the relays using the test func-

tion as follows:

a. Press

and the display will read

b. Press the

q

to scroll down until the display reads

“CPA1 OFF.”

c. Press

, and the compressor should start.

d. Press ,

a

and the compressor should stop.

e. Press c l until the display reads

OFF.”

f. Press

, and the solenoid should energize.

g. Press

q

and the solenoid should deenergize.

h. Use the

and

keys to check the remainder of

the unloader coils.

6. Once the check has been performed, return the LOCAL/

ENABLE-STOP-CCN switch to the proper position.

7. Close and secure the control box door.

8. Start the unit and confirm that the chiller operates

properly.

LEGEND

Communications Bus

Terminal Block

Hot Gas Bypass Relay

Transformer

Normally Open

S n u b b e r

Unloader

Unloader Relay

Fig. 24 - Flotronic’” II

Unloader Wiring, 130 (50 Hz), 150-210, 225, 250, 280

7 0