Lock-up row – Great Plains 1625AHL Operator Manual User Manual

Page 88

84

1625AH

Great Plains Manufacturing, Inc.

411-020M

2014-04-21

Blank disks (part number 817-841C) are essential in row

shut-off, both to maintain consistent meter back-pressure

to meter pressurization and to prevent wear on seed

disks and minimize wear on brushes.

Blank disks are engineered to simulate a seed disk with

seed in all pockets. Blanks are particularly important on

the rows with sensor lines to the pressure chamber.

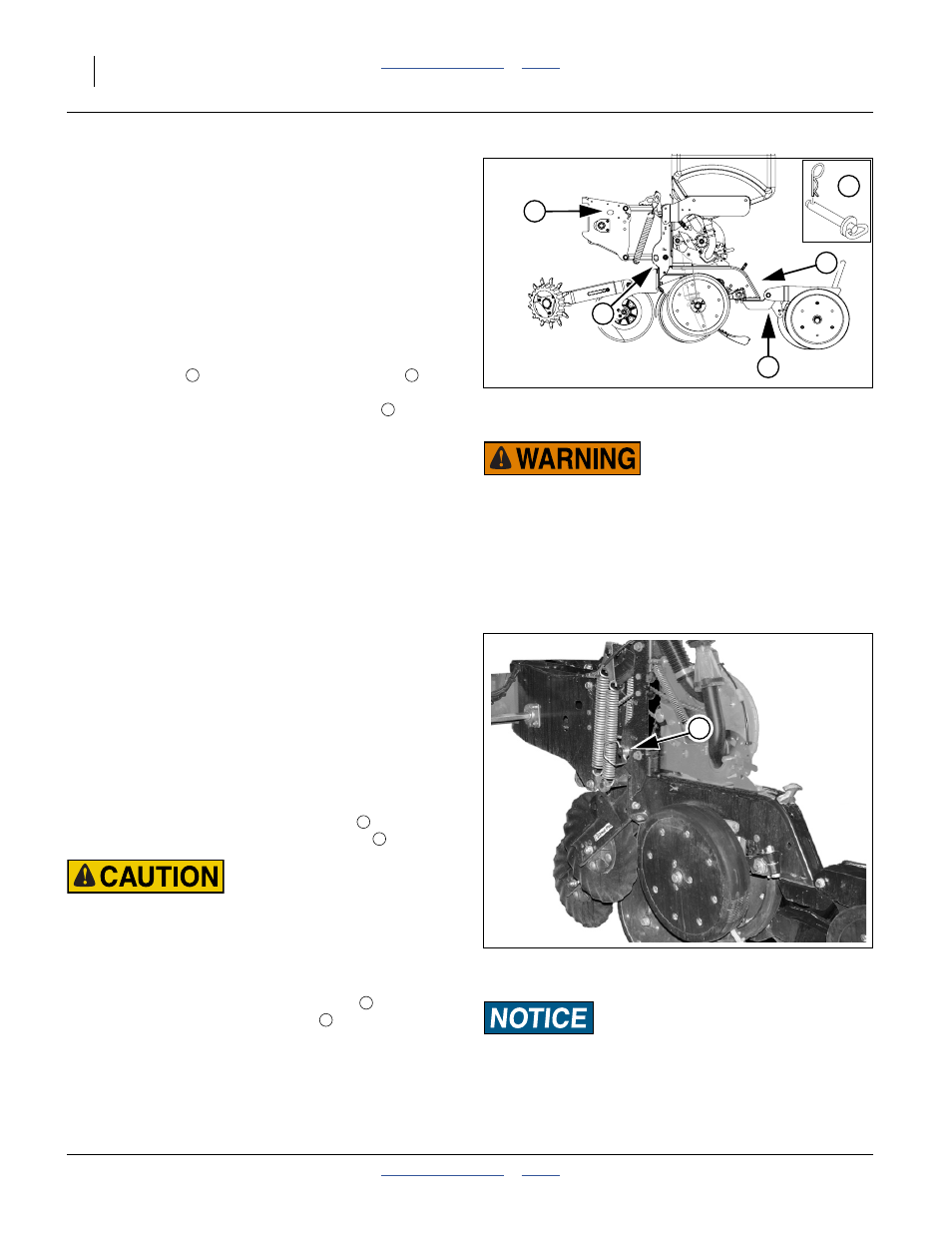

4. Lock-Up Row

Alternate twin-row units (the rear units) can be pinned in

the up position to accommodate single-row spacing.

Refer to Figure 88

The lock-up pins

are located in a storage hole

in

the row unit mount. To lock up a unit, the unit must be

raised, and the pin moved to the lock-up hole

in the

row unit shank.

Note: Lock-up pins are provided for every other row of

twin-row configurations. If you lose a pin, the

replacement part number is 805-435C

1.

Raise the planter. Although this adjustment can be

made with the planter lowered, the springs will be in

tension, and will require more effort. The extra force

may also damage tools.

2.

Install lift assist cylinder locks. Lower parking stands.

3.

Set the down pressure spring cam to zero, per the

instructions on page 72.

4.

Raise the row unit high enough that the hole for the

pin is above the lower parallel arm. This can be done

in several ways, including:

a. use a hoist at the rear of the shank

b. use a jack under the shank extension

Crushing Hazard:

Use a jack or hoist. Raising a row unit on a block by lowering

the planter is risky. The potential for hydraulic failure creates

a safety hazard. Full lowering can damage components.

Refer to Figure 89

5.

Remove the pin from the storage hole

and insert

and secure it in the lock-up hole

.

6.

Lower row unit until lock-up pin rests on lower

parallel arm.

Crushing and Sharp Object Hazards:

Do not attempt to lift a row unit by hand. The weight of the

unit, plus the force of the springs (even at minimum) is too

great (plus, a free hand is needed for pin insertion). Even with

multiple people lifting, hand-lifting is unsafe - there are

numerous sharp edges, and the row unit snaps down violently

if a grip is lost.

Figure 88

25AH Series Row Unit Lock-Up Pin

25269

36236

2

3

4

5

1

1

2

3

Certain Machine Damage:

Do not pin the row unit while it is in the lowered position.

If the pin is inserted below the parallel arm, unit damage

occurs as soon as planting begins.

Figure 89

25AP Series Row Unit Locked Up

29756

3

4

5

2

3