Install marker shear bolts, Install marker extension tube, Check disk orientation – Great Plains 1625AHL Operator Manual User Manual

Page 157

Great Plains Manufacturing, Inc.

Appendix B - Pre-Delivery

153

2014-04-21

411-020M

Heavy Overhead Object Hazard:

Use adequate lifting means. Use multiple attachment points.

Use extra personnel to control the load. The arm section may

weight up to 300 pounds (135 kg), and does not balance at the

center of its considerable length. if it falls, or you lose control

of the load, workers could suffer serious or fatal injuries.

20. Orient the arm (

or

) with the shear pin hole to

the rear (flat plate at the hinge end up, angled edge

of plate forward, and the center tube below).

Hoist the arm, resting the single-tube end in the

transport rest, and aligning the shear pivot tube with

the shear pivot holes in the hinge

.

Insert a shear pin

. Secure with second washer

and cotter

.

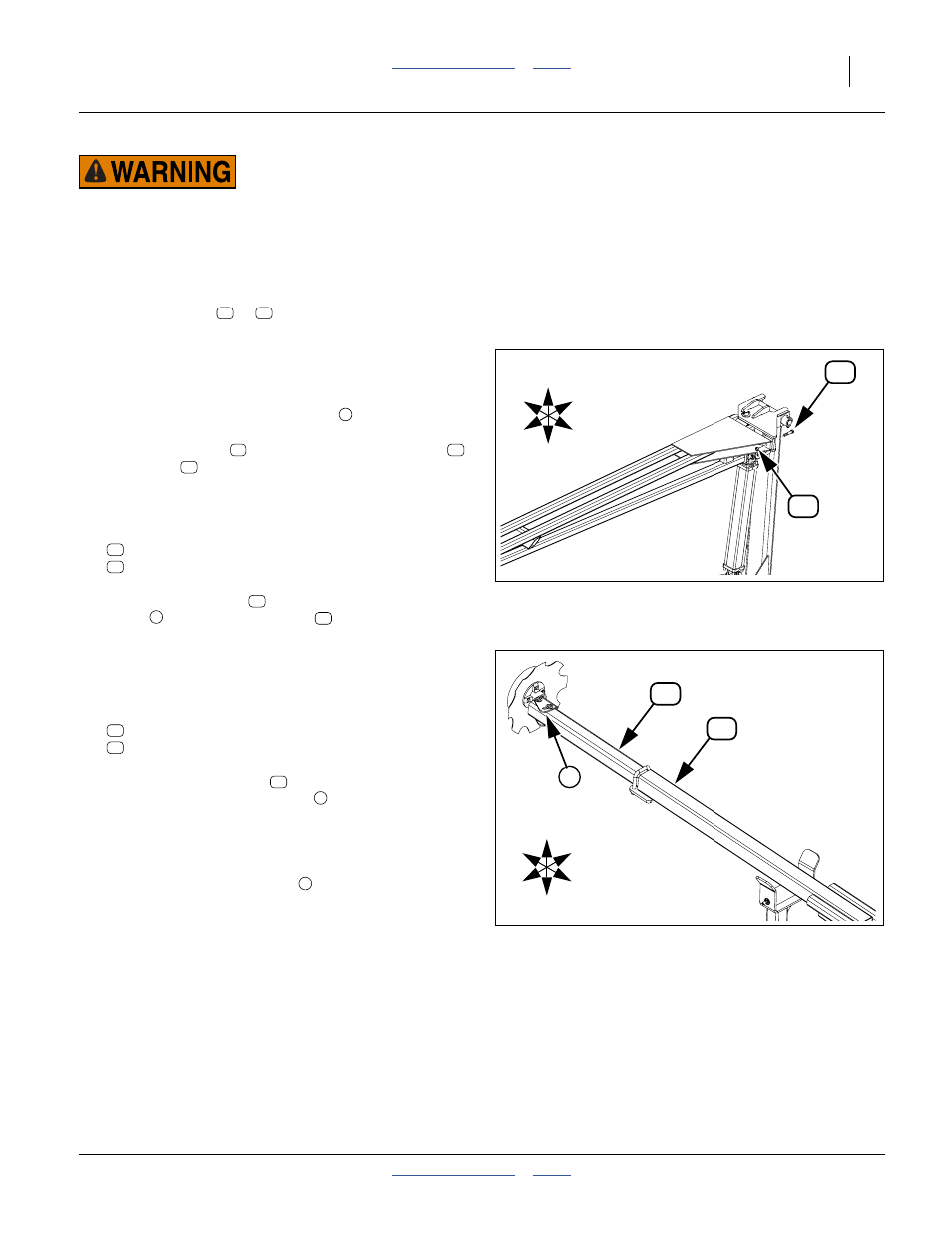

Install Marker Shear Bolts

Refer to Figure 127

21. Select one each:

802-130C HHCS 1/2-13X2 1/2 GR5

803-019C NUT LOCK 1/2-13 PLT

Insert the shear bolt

from the wing end of the

hinge

. Secure with lock nut

.

Install Marker Extension Tube

Check Disk Orientation

Refer to Figure 128 (C: to Center; W: to Wing)

22. Select one of:

113-794D MARKER EXTENSION TUBE

421-555D MARKER EXTENSION TUBE

These tube assemblies

are identical for LH and

RH use. The disk and spindle

are pre-assembled.

Prior to installing the marker extension tube, inspect

the disk assembly. The bolts securing the spindle

weldment to the tube are to be vertical after

installation, and the spindle

is to be to the front.

This is merely the factory default orientation. The

operator may change it as needed.

Figure 127

LH Marker Shear Bolt

24408

U

D

C

W

F

B

33

27

11

12

4

14

42

43

27

33

27

4

33

Figure 128

LH Marker Spindle Orientation

36261

11

5

U

D

F

B

W

C

13

13

13

13

5

5