Air-pro® meter operation, Meter operation, Air-pro – Great Plains 1625AHL Operator Manual User Manual

Page 54

50

1625AH

Great Plains Manufacturing, Inc.

411-020M

2014-04-21

Air-Pro

®

Meter Operation

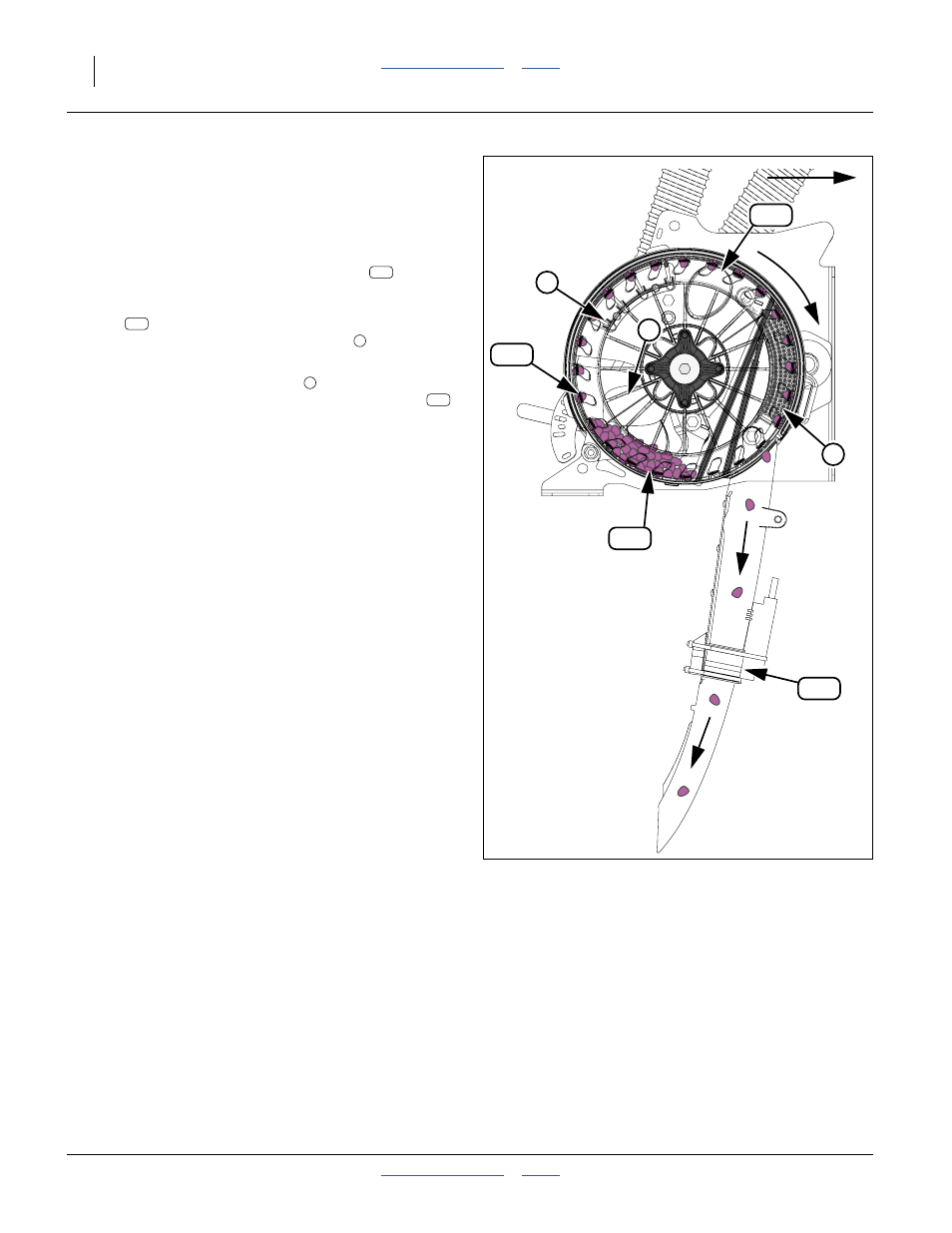

Refer to Figure 37

The meter disk is driven, top forward, by a chain drive

(not shown) always connected to the section drive shaft.

At non-planting rows, use a blank disk (page 83).

Meter pressurization air enters the meter at

, and

exits the meter primarily at the seed pockets in the seed

disk. The pressure differential holds seed in the disk

pockets

rising from the seed pool. Excess seed at a

pocket is picked off by the tickler brushes

.

The strip and drop brushes block meter pressurization

air. Seeds passing the drop brush

are free to fall into

the seed tube, and are detected by the seed sensor

.

Meter Operation

1.

Install disks for your crop/population range per the

Seed Rate Manual and the instructions beginning

on page 81 of this manual.

2.

Open the shutter at planting rows to the

recommended initial setting (from the Seed Rate

charts). At unused rows, install a blank disk

(page 83) and close shutter.

3.

Set sprocket indexing if staggering a twin-row crop

(see Seed Rate Manual for details).

4.

Operate fan to achieve suggested manifold pressure

(Seed Rate Manual, and page 52).

5.

With all rows primed, rotate meters one turn to fill

pockets to edge of drop brush. Rotate the drive shaft

(top forward) with a

7

⁄

8

inch (23 mm) wrench, or raise

and rotate ground drive wheel (top forward).

6.

Leave fan running (to keep seed in top pockets).

Re-install rain covers. Commence planting.

Meter operation is automatic from this point on.

See also:

“Seed Pool Troubleshooting” on page 89,

“Material Clean-Out” on page 103, and

“Meter Brush Maintenance” on page 112.

Figure 37

Air-Pro

®

Seed Meter at Row

29825

2

7

8

A16

A27

A26

A29

A16

A27

7

8

A29