Insert and secure tube, Press wheel installation – Great Plains 1625AHL Operator Manual User Manual

Page 158

154

1625AH

Great Plains Manufacturing, Inc.

411-020M

2014-04-21

Insert and Secure Tube

For each wing:

Refer to Figure 129 (C: to Center; W: to Wing)

23. Select one:

806-110C U-BOLT 5/8-11 X 3 1/32 X 4 1/2

and two sets:

804-022C WASHER LOCK SPRING 5/8 PLT

803-021C NUT HEX 5/8-11 PLT

Minding the spindle orientation, insert the marker

extension tube

into the marker arm second

section

to a depth of about

a

18 inches (45 cm).

Secure the extension with the U-bolt

, lock

washers

and nuts

.

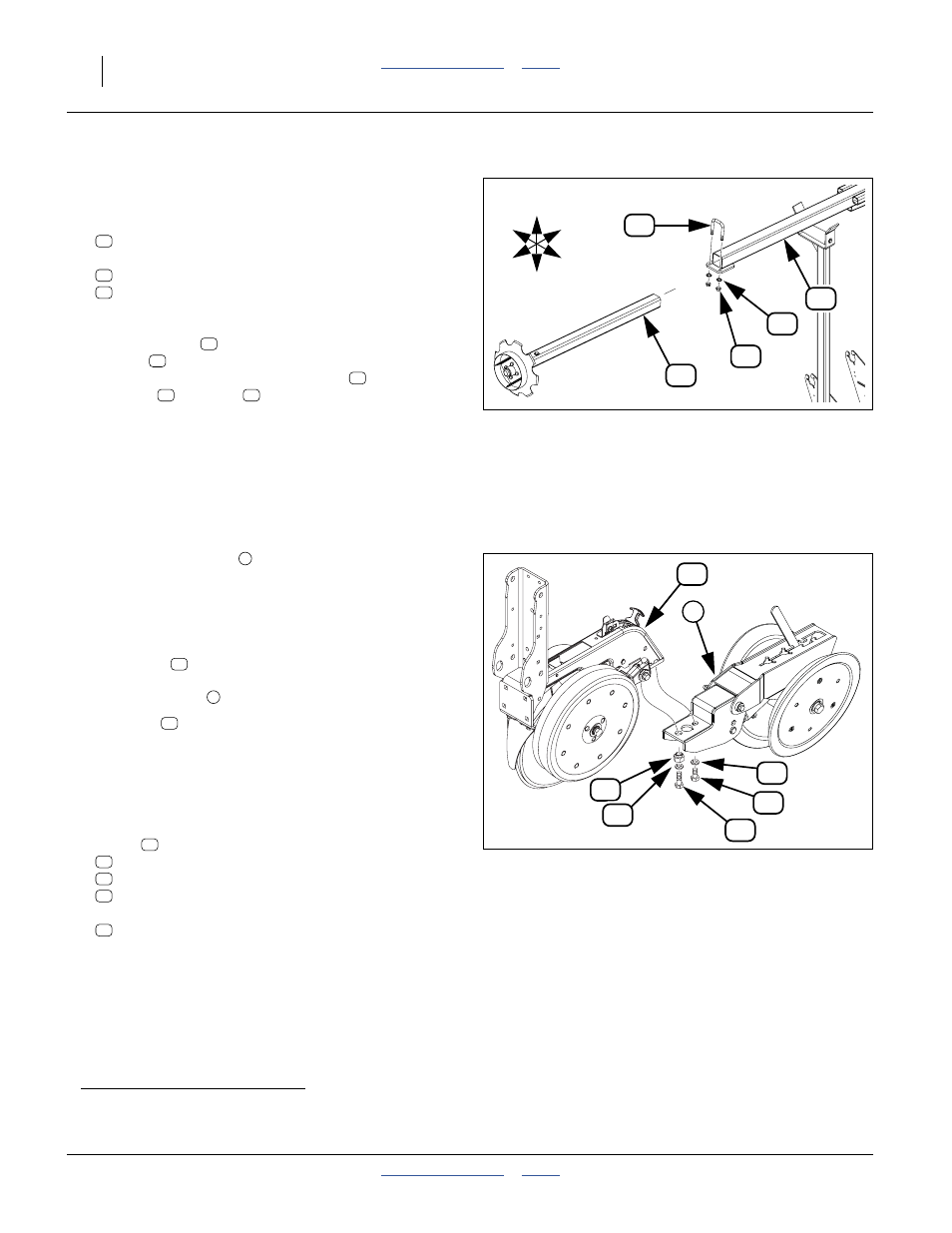

Press Wheel Installation

Refer to Figure 130

Press wheel assemblies

may be removed to meet

shipment clearance requirements. The removed

assemblies are found either in a crate, or a seed hopper.

Refer to Figure 131

There may be two types of press wheel assemblies:

• Long mount

assemblies, which are used on the

front (short) row of a twin pair. These mounts have a

series of notches

on the side.

• Mid mount

assemblies, which are used on the long

(rear) row of a twin pair. These mounts have smooth

sides.

Refer to Figure 130

For each row with press wheels dismounted:

24. Remove from the rear most two bolt holes of the

shank

and save one each:

405-032D 1X12 PW ADJUSTER

802-091C HHCS 1/2-13X1 1/2 GR5

802-258C HHCS 1/2-13X1 GR5

and two:

804-015C WASHER LOCK SPRING 1/2 PLT

a. Exact extension value depends on row spacing, row utilization and desired disk angle. Setting this requires full monitor and hydraulic

connections, then unfolding the planter and markers in field conditions. See “Marker Extension” on page 161.

Figure 129

LH Marker Extension Tube

24408

U

D

C

W

F

B

45

13

41

35

11

45

41

35

13

11

45

41

35

Figure 130

Press Wheel Installation

25383

20

6

21

40

26

40

29

6

18

7

19

20

21

26

29

40