Dry fertilizer fan adjustment, A33 a14 – Great Plains 1625AHL Operator Manual User Manual

Page 59

Great Plains Manufacturing, Inc.

Operating Instructions

55

2014-04-21

411-020M

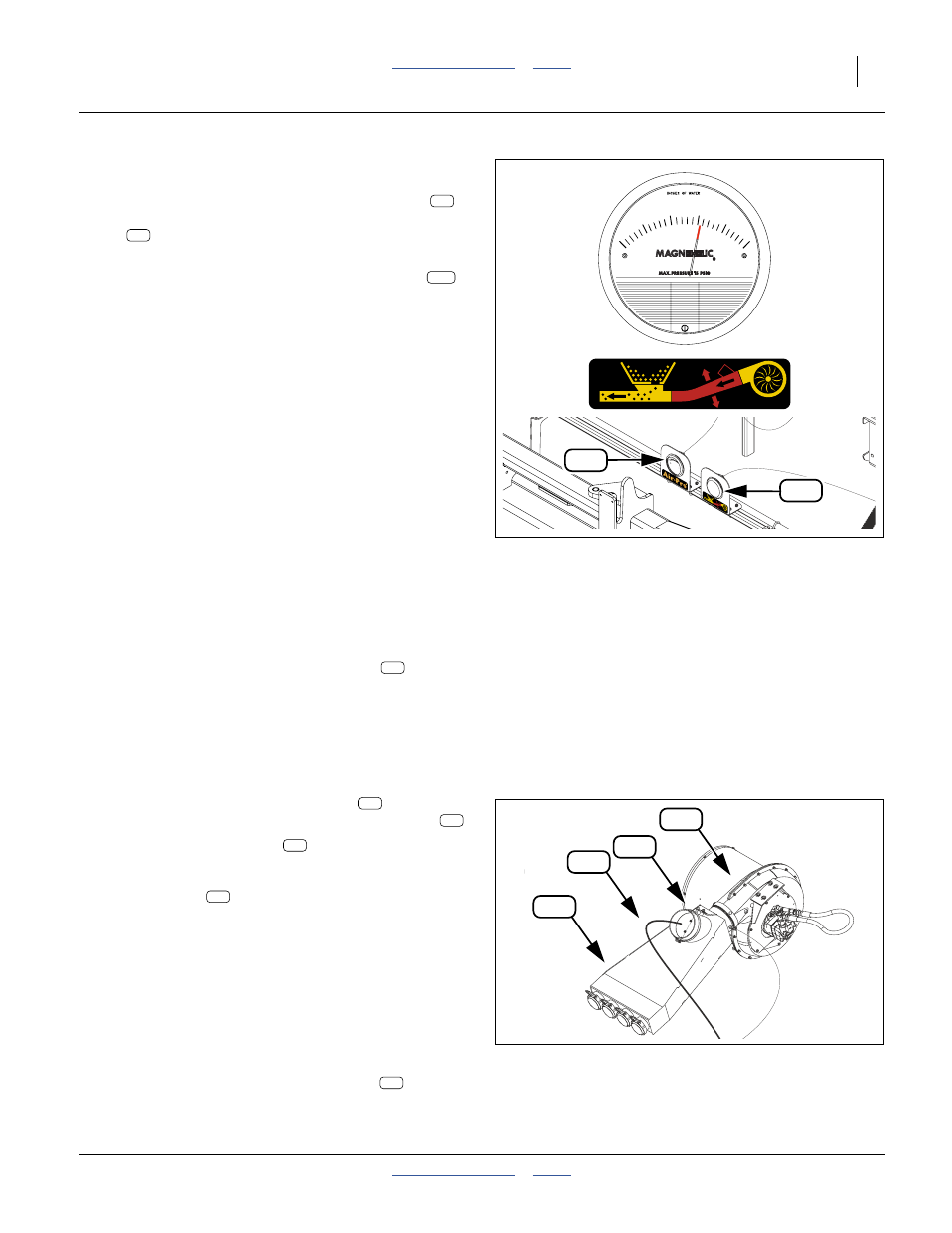

Dry Fertilizer Fan Adjustment

Refer to Figure 43 through Figure 44

1625AHD models have a third Magnehelic

®

gauge

,

with a fan system decal (right wing, inboard of Air-Pro

®

gauge

). This gauge has a scale of 0-to-50 inches of

water pressure. Typical readings are in the 35-45 range.

This gauge reads pressure inside the fan manifold

The manifold supplies air to both the seed meters (meter

pressurization air) and to the dry fertilizer meter.

Approximately 10% of the air is tapped at the top end of

the manifold for meter pressurization air. The tap fraction

is controlled by a butterfly valve, which has an initial

factory setting of approximately 75

°.

Use the tractor remote lever to set fan speed. Use the

butterfly valve adjustment to adjust air fraction for seed

and fertilizer metering. The objective is to obtain

sufficient pressure to avoid dry fertilizer blockage, and

sufficient seed meter pressure to avoid seeding skips

during end-of-pass marker fold, lift and turn.

Adjustments may be required for different field speeds,

different fertilizer rates or fertilizer composition. For initial

static (parked, no material flow) setup:

1.

Look up the recommended meter pressurization for

the intended crop (see Seed Rate manual). Make a

note of the previous or factory settings of all butterfly

valves. Load seed in hoppers and meters. Meters

must be full to inlet shutters for valid readings.

2.

Close the manifold outlet butterfly valve

(set to 90

°). If the wing butterfly valves have been

previously adjusted for balance, leave them

undisturbed, otherwise set them full open (0

°).

3.

For setup, operate the tractor engine at typical field

rpms, and not at idle. Run the fan at maximum oil

flow without over-speeding.

4.

Adjust manifold outlet butterfly valve

to achieve

recommended pressure on the Air-Pro

®

gauges

5.

Re-check both pressures

in the field, with

material flowing at desired rates. Adjust fan speed to

stay within 35 to 45 inches. Adjust the manifold outlet

butterfly valve

to the suggested pressure for the

seed.

Check all pressure early in the first pass, with fertilizer

flowing and seed disk pockets full. Adjust fan speed as

necessary. Stop and adjust butterfly valves as needed to

keep gauges in the desired range.

When planting and applying, check the seed monitor for

skip/double and fertilizer blockage alarms. Check gauge

pressures with full meters and at field speed. Adjust the

fan rpm to compensate for average pressure shifts.

Re-adjust the manifold outlet butterfly valve

for

optimal meter pressurization.

Note: Fan speed and manifold pressures changes

between application and no-fertilizer-metering

states. Monitor fan rpm, meter pressurization,

fertilizer blockage detection and fan pressure

gauge during application and turns.

Note: Fan rpm is dependent on back-pressure due to

material flow. Fan speed increases when flowing

material, due to cavitation.

Figure 43

Fertilizer Manifold (Fan) Gauge

31187

858-193C

36134

A14

0

10

30

20

40

50

858-193C

A14

A15

Figure 44

Fertilizer Manifold Butterfly Valve

36134

858-208C

A16

A11

A15

A15

A14

A15

A15