Marker adjustments, Dual marker speed adjustment, Marker disk adjustment – Great Plains 1625AHL Operator Manual User Manual

Page 72

68

1625AH

Great Plains Manufacturing, Inc.

411-020M

2014-04-21

Marker Adjustments

See also:

“Marker Extension” on page 161 and,

“Marker Maintenance” on page 116.

Pinch, Crush and Sharp Object Hazards:

Never allow anyone near the planter when folding or

unfolding the markers. You may be injured if caught or struck

by a folding or unfolding marker. Markers may fall quickly and

unexpectedly if the hydraulics fail.

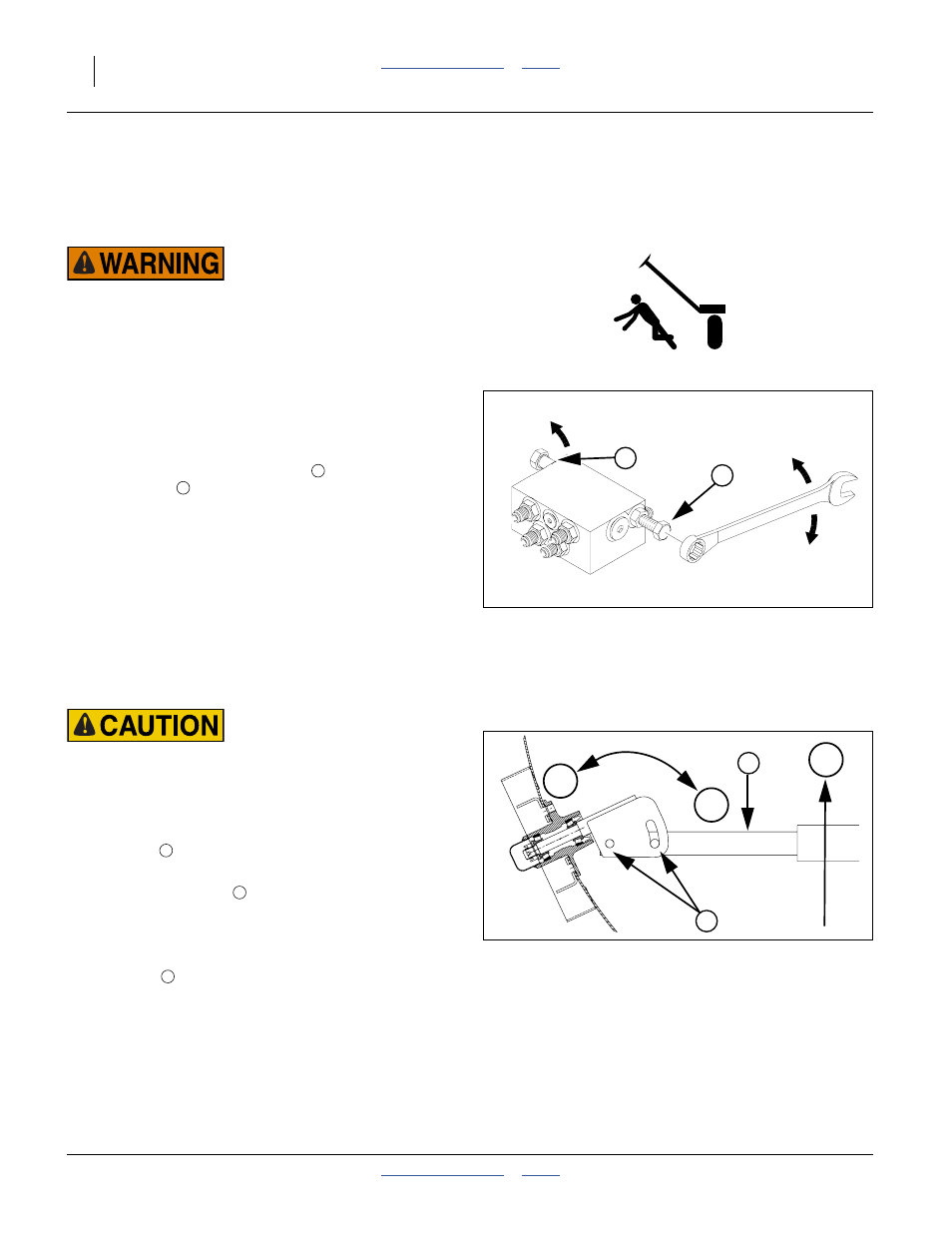

Dual Marker Speed Adjustment

Refer to Figure 53

Adjust folding speed for dual markers with hex

adjustment screws on sequence valve body. There is an

adjustment screw for raising speed

and one for

lowering speed

. You can identify adjustment screws

by markings stamped in the valve body.

Turn adjustment screws clockwise to decrease folding

speed and counterclockwise to increase folding speed.

With tractor idling at normal operating speed, adjust

marker folding to a safe speed. Excessive folding speed

could damage markers and void the warranty.

After adjusting folding speed, tighten jam nuts on hex

adjustment screws to hold settings.

Marker Disk Adjustment

Sharp Object Hazard:

Use caution when making adjustments in this area. Marker

disks may be sharp.

Refer to Figure 54

To change angle of cut, and the width of the mark, loosen

1

⁄

2

-inch bolts

holding disk assembly.

For a wider mark (W), increase the angle of the marker

with respect to the tube

. For a narrower mark (N),

reduce the angle.

You can also invert the disk blade on the hub to change

the direction of throw.

Tighten bolts

.

Note: The direction of travel (T) tends to drive the disk

angle to Wide. If bolts are not tight enough, or

loosen over time, the disk will slip into the Wide

mark configuration.

Figure 53

Marker Extension Adjustment

14048

F

S

S

1

2

1

2

Figure 54

Marker Disk Angle

11757

N

W

T

4

6

6

4

6