Preparation and setup, Tramlining – Great Plains V-300F Predelivery Manual User Manual

Page 37

1/2/2006

148-057Q

35

Preparation and Setup

Preparation and Setup

Tramlining

All tramlines for this drill were set up on the fol-

lowing assumptions:

• 3 meter planting width with 19 openers

equally spaced at 15.8 cm.

• 1.8 meter wheel spacing of the tramlines.

With these assumptions, the feeder cup al-

lows for the tramline clutches to be placed on

rows 1, 4, 6, 13, 14, and 16. Two clutches are

assembled as standard on rows 4 and 16. An

additional clutch and jumper cable will be re-

quired on some patterns (ie 20 meter sprayer/

20 bouts).

The tramline clutch locations are as follows:

• 12 meter sprayer/4 bouts:

a.

Asymmetric right or left hand.

i.

Tramlines will be on rows 6 and

14.

b.

Symmetric.

i.

Tramlines will be on rows 4 and

16 (2nd bout must overlap 1st

bout 1/2 drill width).

• 15 meter sprayer/5 bouts:

a.

Symmetric.

i.

Tramlines will be on rows 4 and

16.

• 18 meter sprayer/6 bouts:

a.

Asymmetric right or left hand.

i.

Tramlines will be on rows 6 and

14.

b.

Symmetric.

i.

Tramlines will be on rows 4 and

16 (2nd bout must overlap 1st

bout 1/2 drill width).

• 20 meter sprayer/20 bouts

a.

Special Pattern:

i.

Tramlines will be on rows 1, 13,

and 14. (This pattern requires an

optional clutch and jumper cable,

which connects rows 1 and 13 to-

gether).

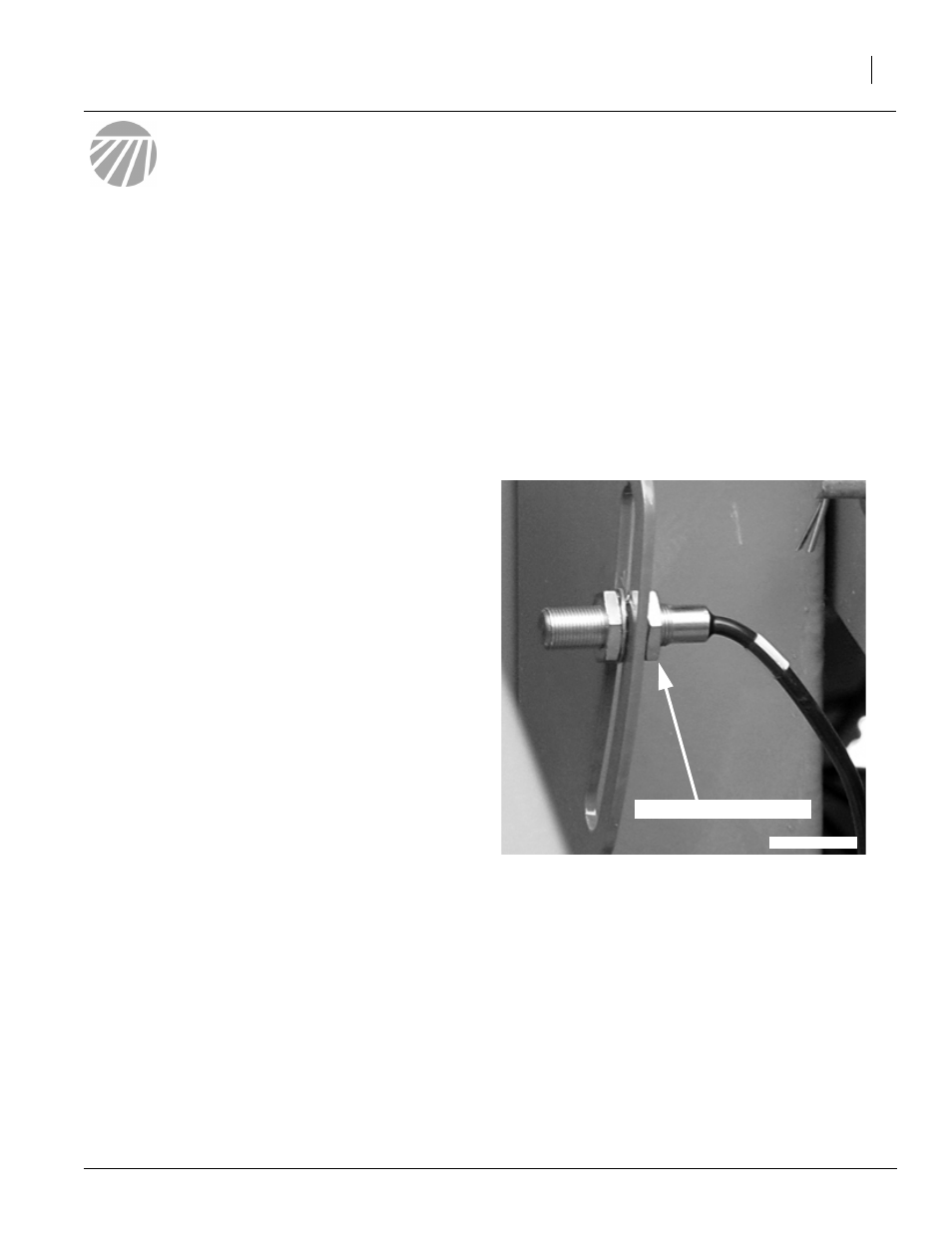

Refer to Figure 60

NOTE: On Tramline adjust screw to 1/8” of

magnet. Screw can also be adjusted up or

down in the slot. When drill is raised, the

sensor should be right on the magnet.

Otherwise, if sensor passes magnet it may

possibly read more than once.

On shaft monitors, adjust screw to 1/8” of

magnet. Screw will not adjust up or down.

Adjustment Screw

23387

Figure 60

Adjustment Screw