Press wheel – Great Plains V-300F Predelivery Manual User Manual

Page 22

V300, V300F

148-057Q

1/2/2006

20

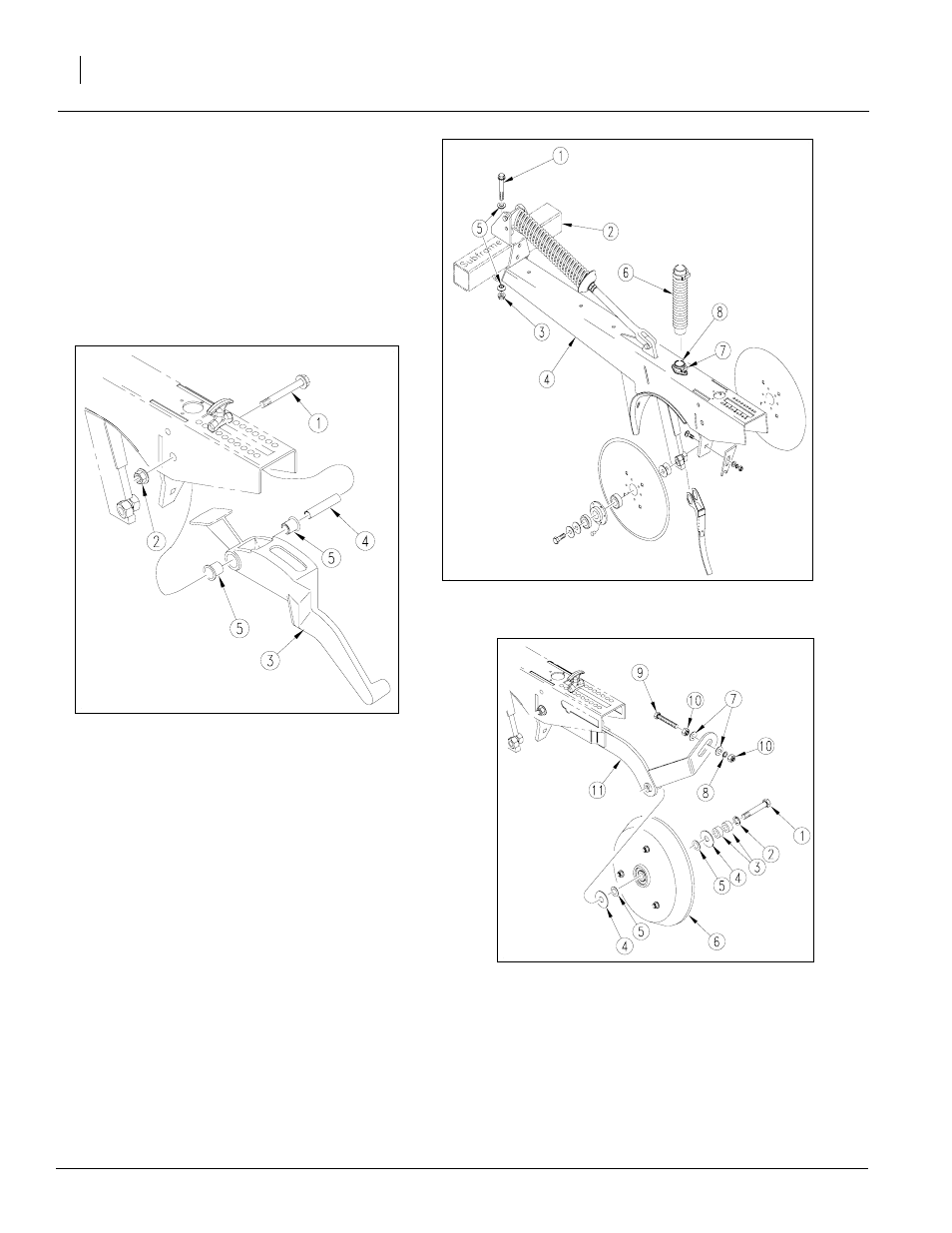

Refer to Figure 32

NOTE: For shipping purposes, the two end openers

were removed from the subframe. They will need to

be reinstalled according to steps 3 and 4 below.

3.

Attach the two end openers (4) to the opener

subframe (2) - one on each end of the subframe

(2). Secure openers (4) to subframe (2) using

bolts (1), washers (5), and lock nuts (3).

4.

Connect seed hose (6) to seed tube opener (8)

securing with hose clamp (7).

Figure 33

Attach Press Wheel Arm to Opener

Figure 32

Attach Opener to Subframe

23353

23358

Figure 34

Cast Press Wheel

23354

Press Wheel

Refer to Figure 33

NOTE: The press wheel arm weldment will need to be

installed on the two end openers. Install as shown in

Figure 33.

1.

Attach press wheel arm weldment to opener using

bolt (1), parallel arm pivot bushings (5), press

wheel pivot tube (4), and hex lock nut (2).

Refer to Figure 34

NOTE: Each type of press wheel installs differently. If

installing 2” x 13” or 3” x 13” single press wheel, com-

plete only step 2.

If installing cast press wheel, complete both steps 2

and 3.

For all press wheel types:

2.

Attach press wheel (6) to press wheel arm weld-

ment (11). Secure press wheel (6) to weldment us-

ing bolt (1), lock washers (2), spacer bushings (3),

and washers (4 and 5).

For cast press wheel assembly only:

3.

Once the press wheel (6) is attached to the press

wheel arm weldment (11), attach bolt (9), hex

nuts (10), flat washers (7), and lock washer (8) to

press wheel arm weldment.