Powers 595 Series 11 Self-Operating Temperature Regulators - Type WM 3-Way Water Mix User Manual

Page 6

6

4.

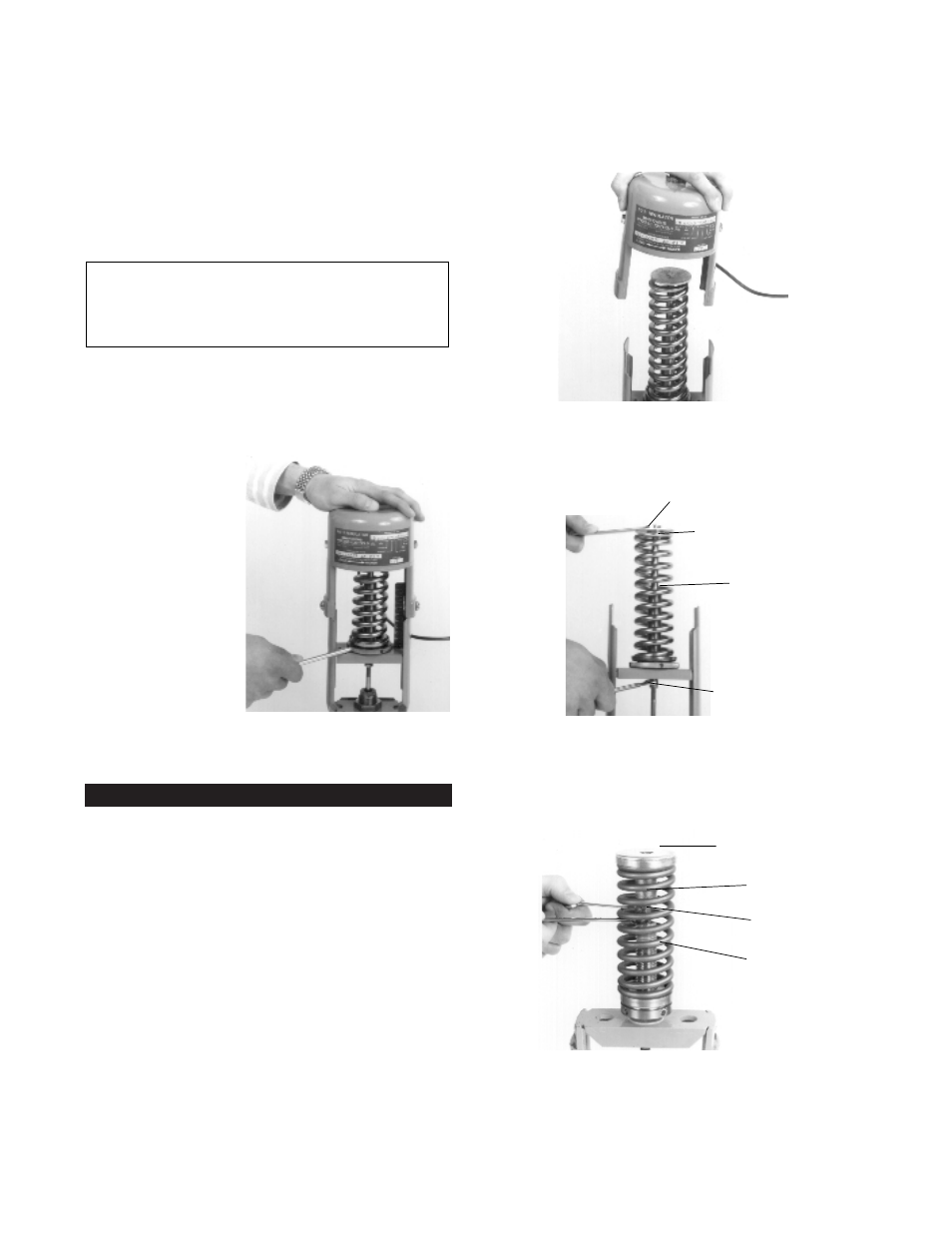

Figure 8. Remove housing bolts [6] and nuts [7] and tempera-

ture adjustment setting scale [8] and lift off thermal system [1]

(housing, bellows, capillary, and bulb).

5.

Figure 9A. For the 1/2" to 2" valves, use one 3/8" wrench and

one 5/16" wrench, carefully loosen and remove piston plate

assembly [2,3] from the stem extension [4].

Lift off spring [19].

Figure 9B. For the 2-1/2" to 4" valves, use two 3/8" wrench-

es to carefully loosen piston plate/shank [3] from the stem

extension [4]. Make sure the spring is fully decompressed,

slowly remove piston plate assembly. Lift off the spring seat

and the spring.

7.

Without a well: Remove bushing from the bulb and screw it

into the tank. Insert the thermostatic bulb through the bushing

and tighten the union nut.

With a well: Do not use bushing. Screw well into tank, insert

bulb directly into well, and tighten union nut.

ADJUST CAPILLARY TUBING

8.

Coil the extra capillary, and position away from regulator oper-

ation where it is subjected to room temperature only.

ADJUST SET POINT

All regulators are factory set to control near mid-range operating

temperature.

9.

When adjusting the set point, make certain all fluids are flow-

ing through the

valve and are at the

operating pressure

of the system.

10. Figure 7. Make all set

point temperature

changes by insert-

ing the temperature

adjustment rod into

one of the holes of

the adjusting nut

assembly. (Use the

temperature adjust-

ment setting scale

only for reference)

To Raise the set

point: Turn rod left

to right (counter-

clockwise from top).

To Lower the set

point: Turn rod right

to left (clockwise from top).

MAINTENANCE

Numbers in brackets [#] refer to part numbers on pp. 12 & 13.

To fully disassemble regulator from valve

1.

Figure 3. For 2-1/2” to 4” valves, replace bellows stops

before performing any service or maintenance.

2.

Before disassembly, the bulb must be cooled 30°F (16°C)

below the lowest point on the thermal system range, and flow

through the valve must be stopped.

3.

Figure 7. Relieve all pressure on the spring by turning adjust-

ing nut assembly [31] fully right to left (clockwise from top).

WARNING: DO NOT kink, cut, sever or file the tubing.

DO NOT disconnect tubing from bulb or bellows

assembly. This can render the thermal system inopera-

ble and result in severe process overheating.

7. ADJUSTING SET POINT

8. REMOVE HOUSING AND THERMAL SYSTEM

3/8" Nut

5/16" Nut

Piston Plate

Assembly

Spring

9A. (1/2" TO 2") REMOVE PISTON PLATE AND SPRING

9B. (2-1/2" TO 4") REMOVE PISTON PLATE/SHANK AND SPRING

Piston Plate/

Spring Seat

3/8" Shank

3/8" Stem

Extension

Spring