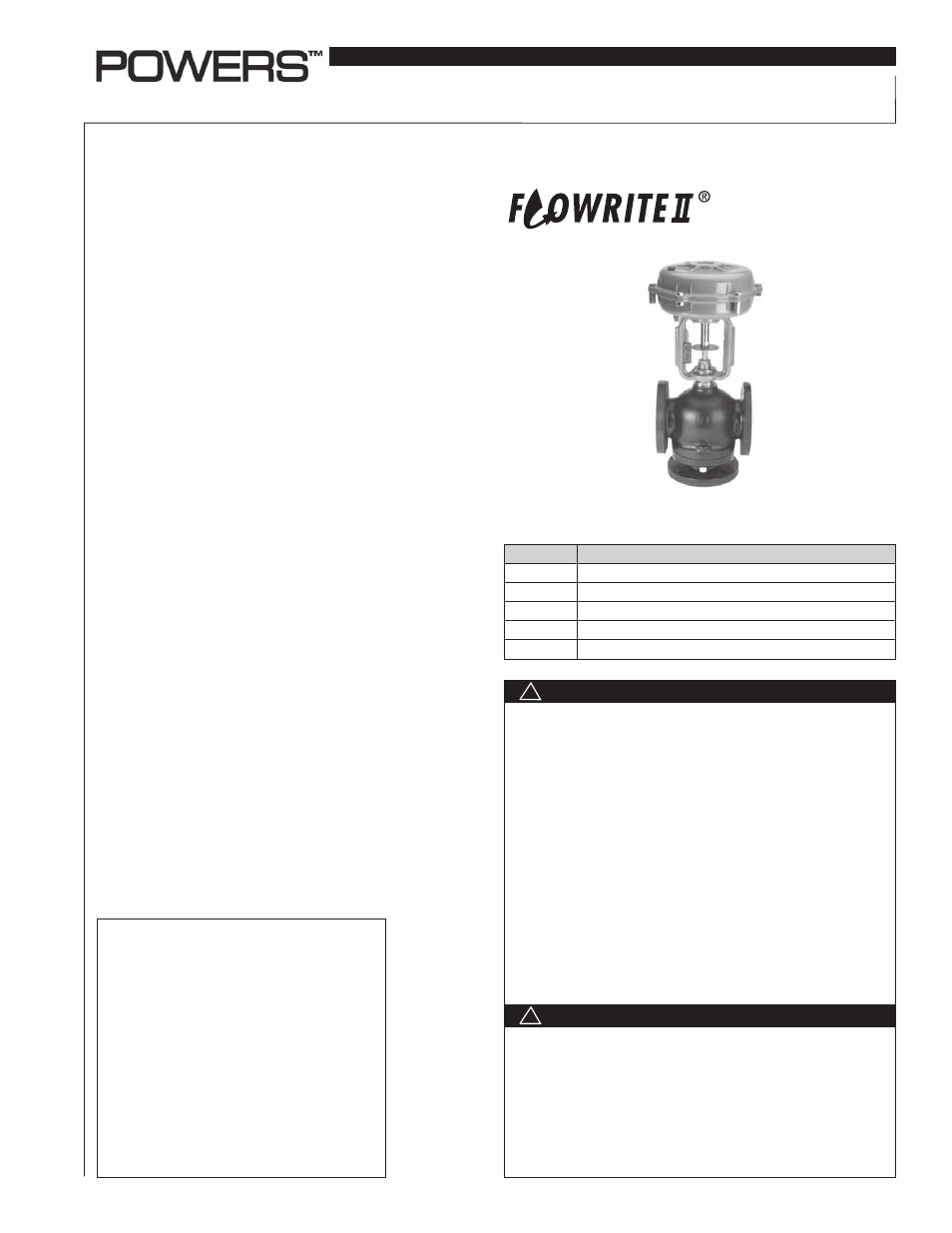

Powers 596 Series Flowrite II Heavy Duty Control Valves - Type MI Mixing User Manual

Technical instructions

Powers Flowrite II Water Mix (MI) Valves combine hot and

cold water proportionally to satisfy the demands of the con-

trolling instrument.

The valve's linear inherent characteristic produces equal

changes in flow per unit of valve stroke regardless of plug

position. The valve is air operated and can be used in a vari-

ety of mixing applications.

Description

n

Flowrite II

Iron Body Series 596 MI

Technical Instructions

IS-P-596MI

596 MI with 46 in

2

actuator shown

Sizes

Actuators Available

2 1/2"

46 in

2

or 100 in

2

Diaphragm

3"

46 in

2

or 100 in

2

Diaphragm

4"

46 in

2

or 100 in

2

Diaphragm

5"

100 in

2

Diaphragm

6"

100 in

2

Diaphragm

Specifications

n

VALVE

Body Sizes: ................................ 2 1/2" – 6"

Body Material: .......................... Cast Iron

(per ASTM A126-93 Class B)

End Connectors: ....................... 125 # Flanged

(per ASNI B16.1-1993)

Trim: ........................................... Bronze

Packing: ..................................... Spring loaded TFE packing

Seat Leakage: ........................... ANSI Class III; <0.1% leakage

Cv Range: .................................. 74-390

Rangeability: ............................. 100:1

Characteristics: ........................ Linear/Mixing

Maximum Pressure: ................ 200 psi @ Temp. <150°F

Max. Differential Press.: ......... 50 psi

Temperature Range: ................ 40 – 281° F

ACTUATOR

Housing Construction: ............. Die cast aluminum

Diaphragm Construction: ........ Replaceable molded neoprene

Diaphragm Area: ...................... 46 in

2

, 100 in

2

Maximum Press. and Temp: .. 35 psi and 200°F

Ambient Shipping Limits: ........ -40 to 220° F

Ambient Operating Limits: ...... -20 to 220° F

Air Connection: ......................... 46 in

2

1/4" NPT

100 in

2

1/8" FNPT

Position Indication: .................. 1/8" increments

Mounting: .................................. In any upright position with

actuator head above 45° of the

center line of the valve body.

Actuator head may be swiveled

to any convenient position.

Table of Contents

n

Description ..................................................... 1

Specifications ................................................ 1

Application Information ............................... 2

Theory of Operation ..................................... 2

Valve Sizing and Selection ...................... 3-4

Close Off Data ................................................ 5

Temperature/Pressure Ratings ................. 5

Dimensional Data ......................................... 6

Installation ...................................................... 7

Maintenance ................................................. 7

Ordering Information .................................... 8

FAILURE TO COMPLY WITH PROPER INSTALLATION AND

MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO

THE VALVE FAILURE.

Watts Hot Water Master Tempering Valves cannot be used

for tempering water temperature at fixtures. Severe bodily

injury (i.e., scalding or chilling) and/or death may result

depending upon system water pressure changes and/or

supply water temperature changes. ASSE standard 1016,

1069 or 1070 listed devices should be used at fixtures to

prevent possible injury.

The Watts Hot Water Tempering Valves are designed to be

installed at or near the boiler or water heater. They are not

designed to compensate for system pressure fluctuations

and should not be used where ASSE standard 1016, 1069 or

1070 devices are required. These Watts valves should never

be used to provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a

construction capable of withstanding the high limit output

temperatures of the water heating source.

Need for Periodic Inspection: Periodic inspection by a

licensed contractor is recommended. Corrosive water

conditions, temperatures over 210°F, and or unauthorized

adjustments or repair could render the valve ineffective

for service intended. Regular checking and cleaning of the

valve’s internal components and check stops helps assure

maximum life and proper product function. Frequency of

cleaning and inspection depends upon local water condi-

tions and water temperature.

WARNING

!

WARNING

!