Powers 744 Series Accritem Rigid and Remote Bulb Blind Controllers - Remote Bulb User Manual

Technical instructions, Accritem ii controller remote bulb

Operation

. . . . . . . . . . . . . . . . . . . . . . . .

Direct and Reverse Acting

Adjustment Dial Range — Standard 0 to 300°F (-20 to 100°C)

Maximum Supply Pressure

at Room Temperature

. . . . . . . . .

20-30psi (138-207 kPa)

Air Consumption (max.)

. . . . . . . . . . . .

54.6 cm 3/s (200 SCIM)

Maximum Operating Pressure

. . . . . . . . . .

1,724 kPa (250psi)

Maximum Operating Temperature

. . . . . . . . . . . .

350°F(177°C)

Air Connective

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1/8″ NPT

Shipping Weight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 lbs. (0.9 kg)

Sensitivity (adjustable)

. . . . . . . . . . . . . . . . . . .

4.3 to 24.8 kPa/°C

(0.35 to 2psi/°F)

Maximum Pressure on Wells

Stainless Steel no. 744-082

1000psi (6,890 kPa)

Copper no. 744-111

400psi (2,756 kPa)

TECHNICAL INSTRUCTIONS

Accritem II Controller

Remote Bulb

TI TC744-2

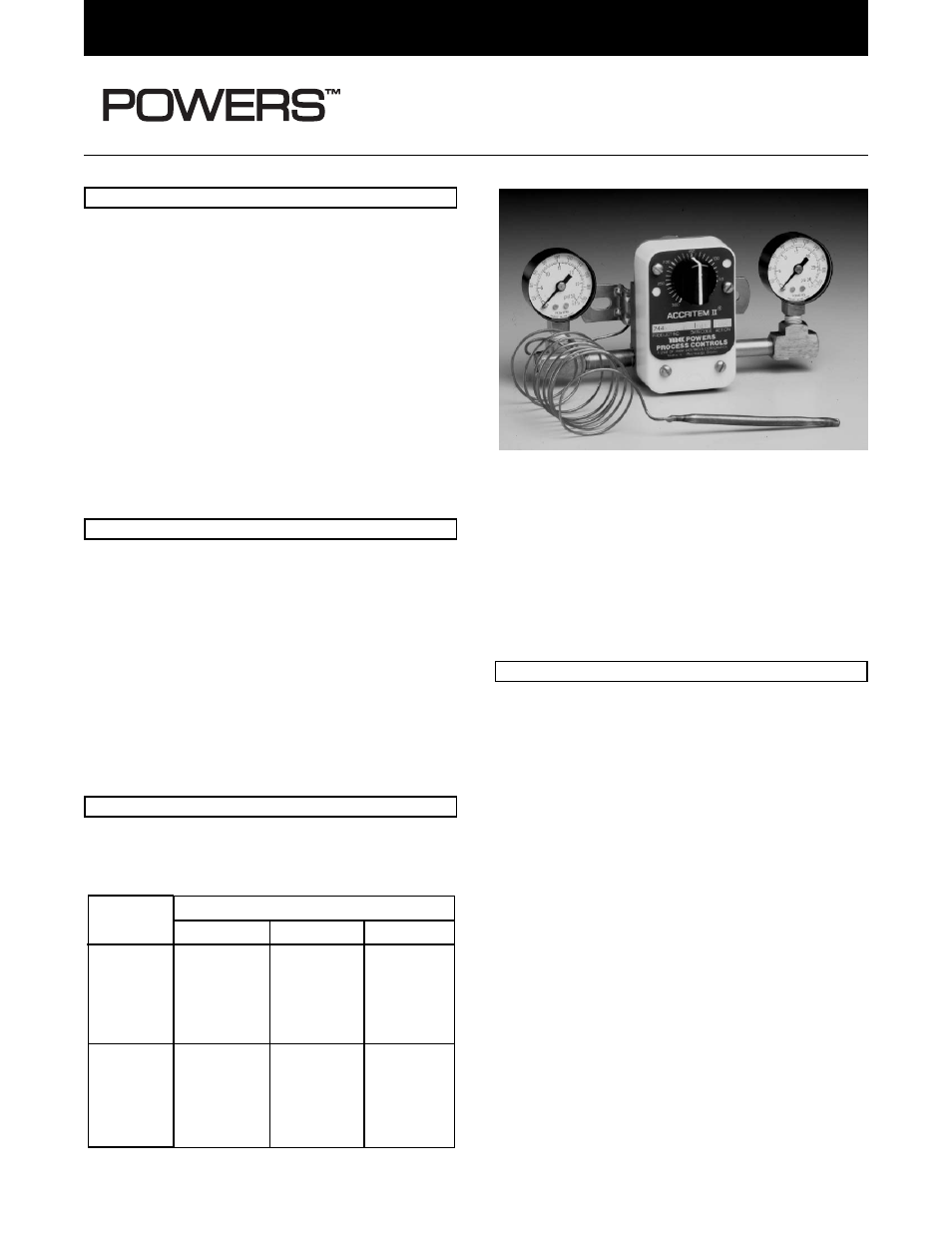

The Accritem II non-indicating temperature controller is a

pneumatically operated instrument recommended for exact

control of temperature in industrial, heating and air condi-

tioning processes. The controller features a liquid filled

thermal system with a remote bulb to sense temperature.

The calibrated dial of the Accritem II has a Fahrenheit range

on one side and a Celsius range on the other. The dial plate

need only be unscrewed and flipped over.

The action of the Accritem II and control valve must be

coordinated for the system to work. See Figure 1.

The Accritem II is an extremely versatile instrument recom-

mended for simple, economical temperature control and

dependable, maintenance-free operation. The compact size

and remote bulb makes it ideally suited for process vats

and ovens, engine cooling systems, instantaneous and

large volume water tanks, chemical process equipment,

etc. The Accritem II can also be used in air handling sys-

tems, humidifier, and in many other applications.

Case: Mount the Accritem II body in any position as close

as possible to the valve being controlled. Use the mount-

ing bracket attached to the back of the Accritem II. Fasten

bracket to any flat surface using any suitable screws in the

2 slotted holes about 3″ (76 mm) apart.

Thermal: Thermal bulb must be located within 48″ (122

cm) of the Accritem II. Thread the well or tank bushing

into the pipeline or tank. Choose a location which is rep-

resentative of the average process temperature. If air

temperature is being controlled, use a duct mounting

flange and support the bulb inside the duct. Carefully

uncoil capillary and insert the bulb into the well, bushing,

or flange. Do not cut or crimp the capillary - protect it

from mechanical damage.

Air Connection: Use 1/4″ (6.4 mm) O.D. copper or plastic

tubing with suitable fittings for the 1/8″ NPT threaded “S”

and “R” connections in the Accritem II body.

Set pressure Reducing Valve to supply 20 to 30psi

(138 to 207 kPa) air to Accritem II.

SPECIFICATIONS

DESCRIPTION

APPLICATION

INSTALLATION

APPLICATION

HEATING COOLING MIXING

Hot Piped to

Normally Open

Normally Closed

Normally Open

Valve

Valve

Port of Valve

Valve Opens to

Valve Opens

Valve Closes

Hot Flow on

on Air Failure

on Air Failure

Air Failure

Hot Piped to

Normally Closed

Normally Open

Normally Closed

Valve

Valve

Port of Valve

Valve Opens to

Valve Closes

Valve Opens

Cold Flow on

on Air Failure

on Air Failure

Air Failure

ACCRITEM

Type

Direct

Acting

Reverse

Acting

Figure 1