Powers 595 Series 11 Self-Operating Temperature Regulators - Sizing Worksheet User Manual

No. 11, Regulator application data sheet, Form ads#11fw

1.

Basic Application

R

■

■

Heating

■

■

Cooling

■

■

Mixing

2.

Capacity

E/O

Cv Rating _______________________________________________

GPM or #/hr. ____________________________________________

2a. Pipe Size____________________________________________

2b. Trim Material

■

■

Bronze

■

■

Stainless

2c. Packing Material

■

■

EP V-Ring

■

■

Teflon V-Ring

3.

Process Load

E/O

• Flow (GPM) of material to be

heated, cooled, or mixed ______________________________

• Temperature increase or decrease

of material ___________________________________________

4.

Media Through Valve

■

■

Steam

Inlet pressure

R

________________________________________

Pressure Drop (

∆

P)

N

___________________________________

■

■

Water

Inlet pressure

R

________________________________________

Pressure Drop (

∆

P)

N

___________________________________

Temperature

R

_________________________________________

■

■

Other

Material Flowing Through Valve _________________________

Inlet Pressure

R

________________________________________

Pressure Drop (

∆

P)

N

___________________________________

Temperature

R

_________________________________________

5.

Media At Sensor (Bulb)

R

• Type

■

■

Water

■

■

Chemical (Specify) _________________________________

• Temperature

■

■

Desired Control Point _______________________________

■

■

Maximum Temperature Exposure ____________________

■

■

Optional Temperature Indicator (Gauge)

6.

Bulb and Capillary Characteristics

R

• Material

■

■

Copper

■

■

316 Stainless

7.

Process Connection, Optional Bulb Well,

Capillary Length

• Process Connection

■

■

Standard Fixed Union with NPT Connection (Style D)

■

■

Special Adjustable Union with NPT Connection (Style JD)

■

■

Special Vertical Fixed Union with NPT Connection (Style V)

■

■

Plain Bulb [No fittings] (Style J)

• Optional Bulb Well

■

■

Copper

■

■

Stainless

• Capillary Length

■

■

8

′

(Standard)

■

■

15

′

(Standard)

■

■

30

′

(Optional)

8.

Part #_______________________________________________

NOTES

R

Required Information

E/O

Either/Or Information

If the required flow rate through the valve (Capacity, Item #2) is

not known, it can be calculated from the Process Load

Information (Item #3).

N

Nice To Have Information

Pressure drops across the valve can be assumed if they are not

specified by the customer.

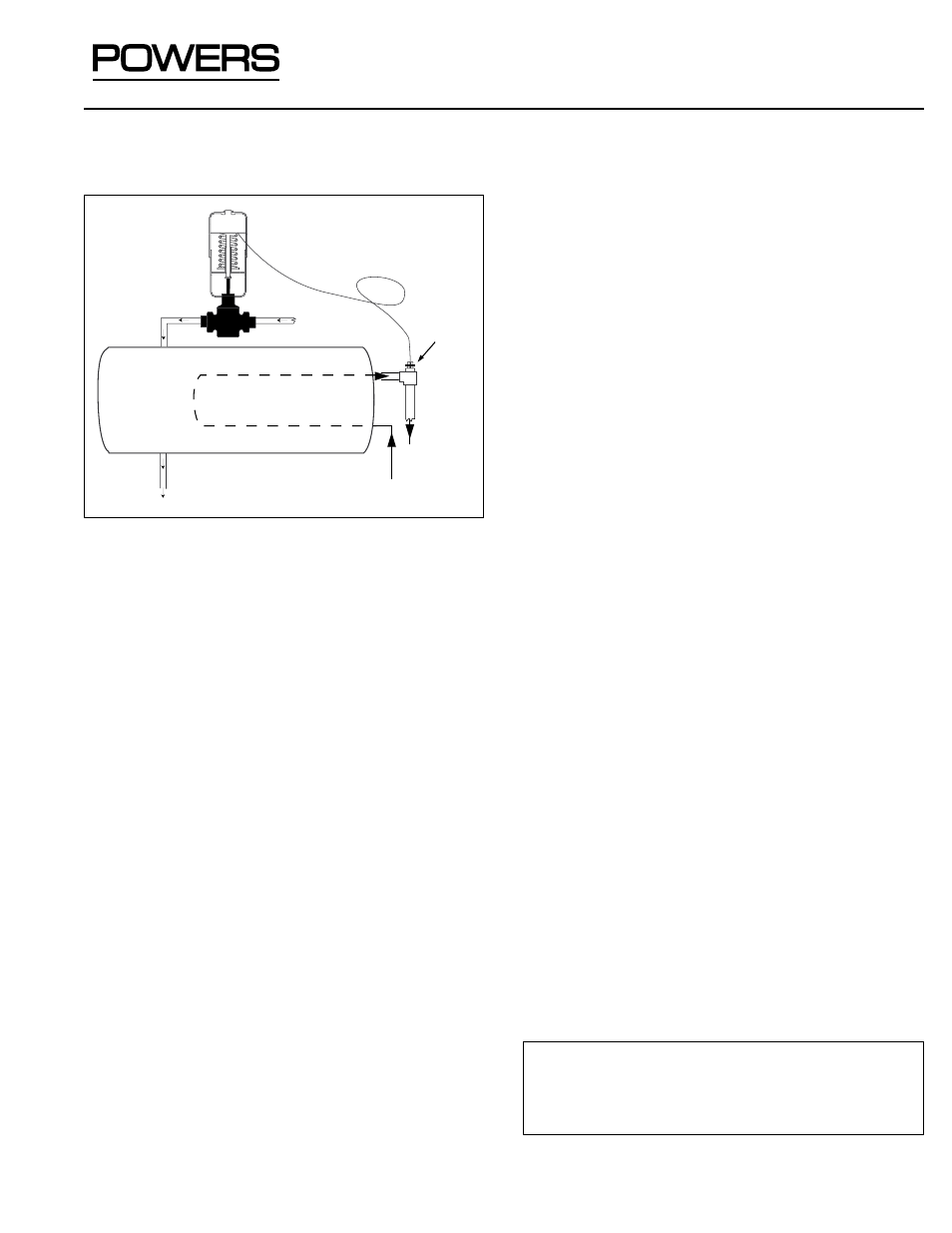

#11 Regulator

Single Seat (CD)

shown

Media Through Valve

Media

at Sensor

(Bulb)

Process

Load

Capillary

Process

Connection

Selecting the correct model regulator for the specific application is extremely important to maintaining a smooth-running

process. To get the regulator that will best meet your needs, please be sure to answer every question noted as “Required”

on this Application Data Sheet.

Sample Application

A Watts Industries Co.

© November 2002 Powers, a Watts Industries Co.

USA Office Phone: 800.669.5430

Canada Office Phone: 888.208.8927

www.powerscontrols.com

Regulator

Application Data Sheet

Form ADS#11FW

No. 11

Page 1 of 2

ADS#11FW 0247

Printed in U.S.A.