Rockwell Automation Low-Voltage Switchgear and Controlgear User Manual

Page 73

equipment and service conditions. With explosion protection type Increased Safety “e” this

particularly requires connection to a correctly selected and adjusted overload protective device.

2.4.7.4

Protection of motors of ignition protection type Increased Safety “e”

For the overload protection of motors of ignition protection type Increased Safety “e”, the

following regulations and standards apply.

- IEC/EN 60947-1, IEC/EN 60947-2 and IEC/EN 60947-4-1 and IEC/EN 60947-8

- IEC/EN 60079-14, Electrical installation in hazardous areas (other than mines), Sections 7 a

and 11.2.1

Among others, the following protective equipment can be considered for use:

- Current-sensing overload protective equipment with delayed release

- Equipment for direct temperature monitoring with the aid of temperature sensors

Protection by current sensing motor protective devices with delayed overload release

Overload protection for motors of ignition protection type “e” must be selected so that it monitors

the rated current I

N

and can switch off a motor with a locked rotor at all poles within the heating

time t

E

. The heating time t

E

is the time after which the permissible temperature of the motor is

reached when the rotor is locked at service temperature. The overload protection must release

according to its cold curve as in most cases the protective relays cool down already after a short

break, while motors take much longer to cool down. The starting (locked-rotor) current I

A

and

the heating time t

E

should be obtained from the rating plate of the motor.

The trip characteristics of the overload protection must always be available at the operating site

or via Internet. The release characteristics should indicate the trip times t

A

with 3-pole loading,

starting from the cold state as a function the starting current ratio I

A

/I

N

– at least 3 to 8 times.

The actual trip times must lie within a tolerance band of ±20 % of the stated values.

The trip times t

A

of the overload protective devices must be smaller than the heating time t

E

of

the motor to be protected for the I

A

/I

N

ratio given.

When selecting the overload relay, it should be noted that although a short tripping time t

A

reliably ensures shutdown within the heating time t

E

, the start up of the motor must be possible

without any disruption.

IEC 60079-7 and EN 50 019 stipulate minimum values for the t

E

time of motors (

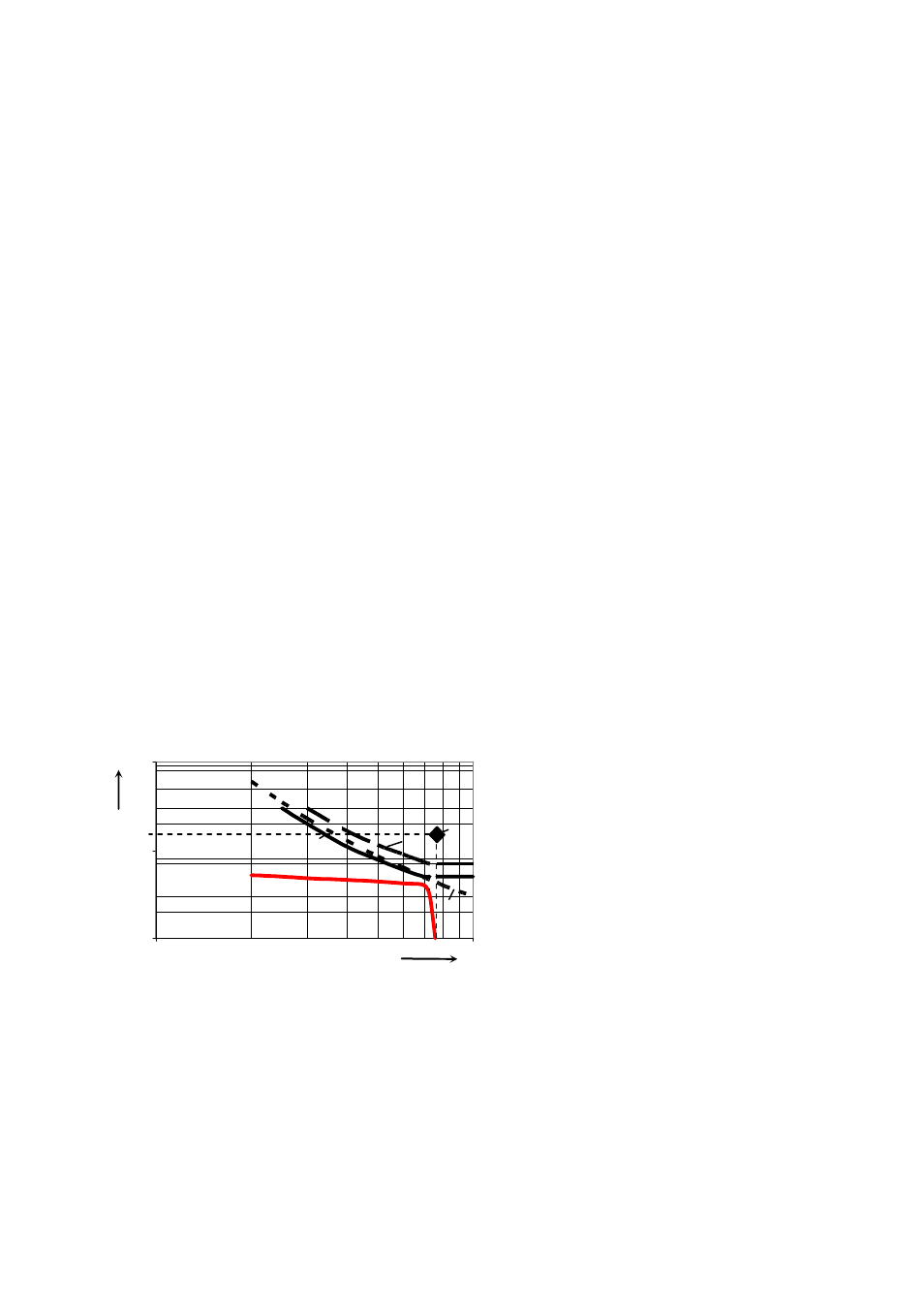

1

10

100

1

10

I

A

/ I

N

7.7

15

t

E,

t

A

[s]

2

3

4

1

Fig. 2.4-16

Heating time t

E

(minimum value) of motors and tripping time t

A

of a circuit breaker with motor protection

characteristic as a function of the starting current ratio I

A

/I

N

1

Minimum values for the time t

E

of motors in accordance with IEC 60079-7 and EN 50019

2

Minimum values for the times t

E

of motors in accordance with recommendation of the

Vereinigung Industrieller Kraftwirtschaft (German “Association of Industrial Power Utilities”)

3

A motor to be protected with t

E

=15 s at I

A

/I

N

= 7.7

4

Trip characteristic t

A

= f (I

A

/I

N

) of a typical circuit breaker with motor protection characteristic of

trip class 10

5

Starting current of the motor

LVSAM-WP001A-EN-P - April 2009

2-45