2 voltage ramp, 3 kickstart, Voltage ramp -24 – Rockwell Automation Low-Voltage Switchgear and Controlgear User Manual

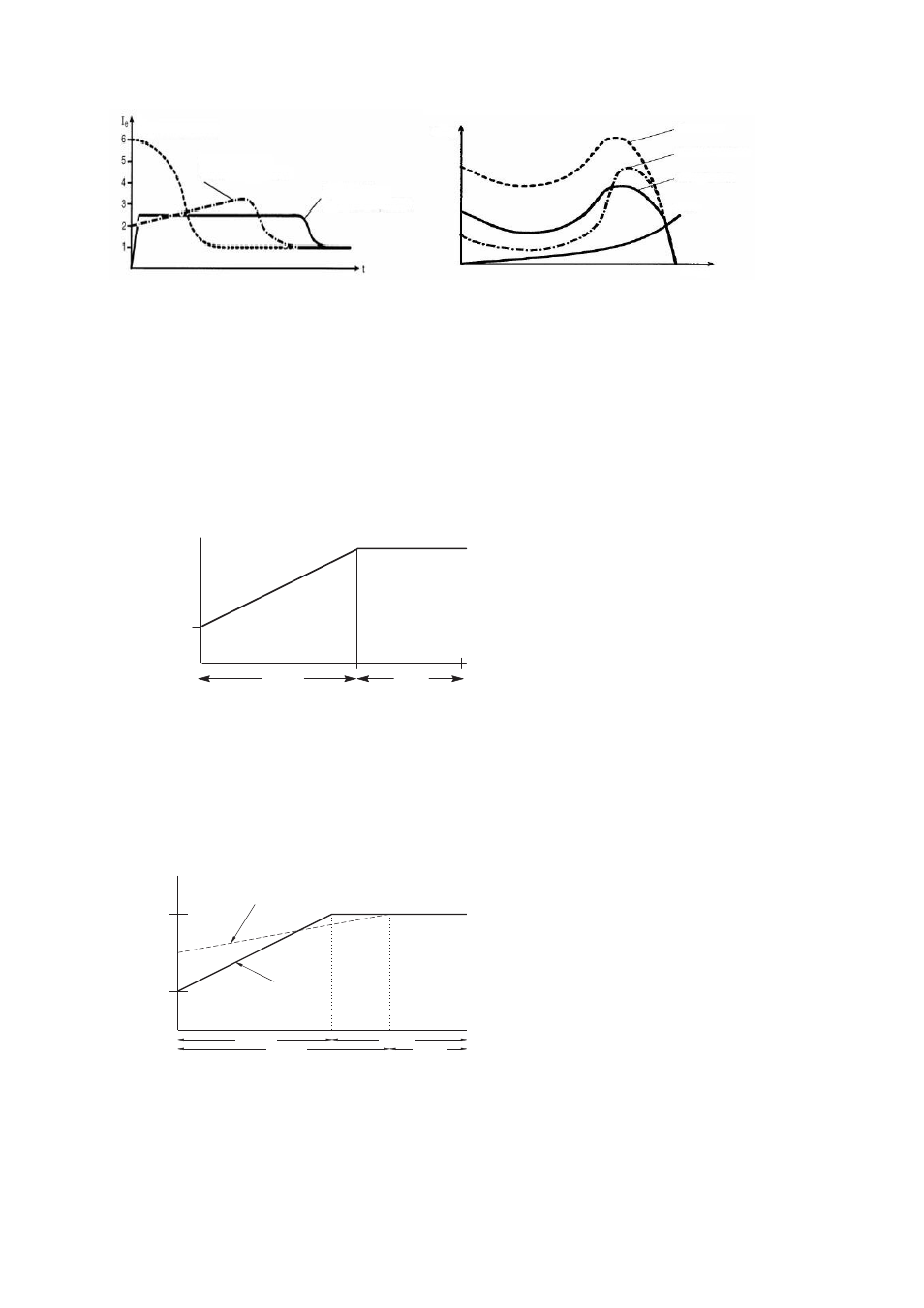

Page 100: Kickstart -24, Produced, Fig. 3.9-1

Direct start

Current at direct

start

T/T

e

Current limit

Current at soft start

with voltage ramp

Current at soft start

with current limit

Voltage ramp

Load

n/n

s

Fig. 3.9-1

Current and torque characteristics for starting

In the following a more detailed discussion of the characteristics of various available soft starter

functions is presented.

3.9.2 Voltage

ramp

The voltage across the motor is linearly increased during a settable time, starting from an

adjustable initial value (

). The starting current and the starting torque, and hence the

acceleration, adjust themselves in accordance with the voltage ramp and the torque characteris-

tic of the load. This method is especially suitable for load-free start-ups and for working ma-

chines with increasing torque requirement at increasing speed (drives with larger inertial

masses, fans etc.).

100%

Percent

Voltage

Initial

Torque

Start

Run

Time (seconds)

Fig. 3.9-2

Soft start with voltage ramp

For drives with variable loading at the start – for example processing machines that normally

start up in a load-free condition, but which can be under load due to a fault – soft starters with

two voltage ramps are available (

). The initial voltages and starting times of ramps are

separately adjustable and hence can be adapted to both operating states. It is possible to

switch between both ramps as required.

Ramp #2

Ramp #1

Start #1

Start #2

Run #1

Run #2

Time (seconds)

Percent

Voltage

100%

Initial Torque

#2

Initial Torque

#1

Fig. 3.9-3

Soft starter with changeable voltage ramp for various loading states at start.

3.9.3 Kickstart

Many drives have a high breakaway torque at rest, because for example bearings surfaces may

generate high initial friction. This requires a short period of increased starting voltage at the

LVSAM-WP001A-EN-P - April 2009

3-24