Rockwell Automation Low-Voltage Switchgear and Controlgear User Manual

Page 163

Avoidance of interfering external influences (foreign particles, chemical effects) at the site of

installation.

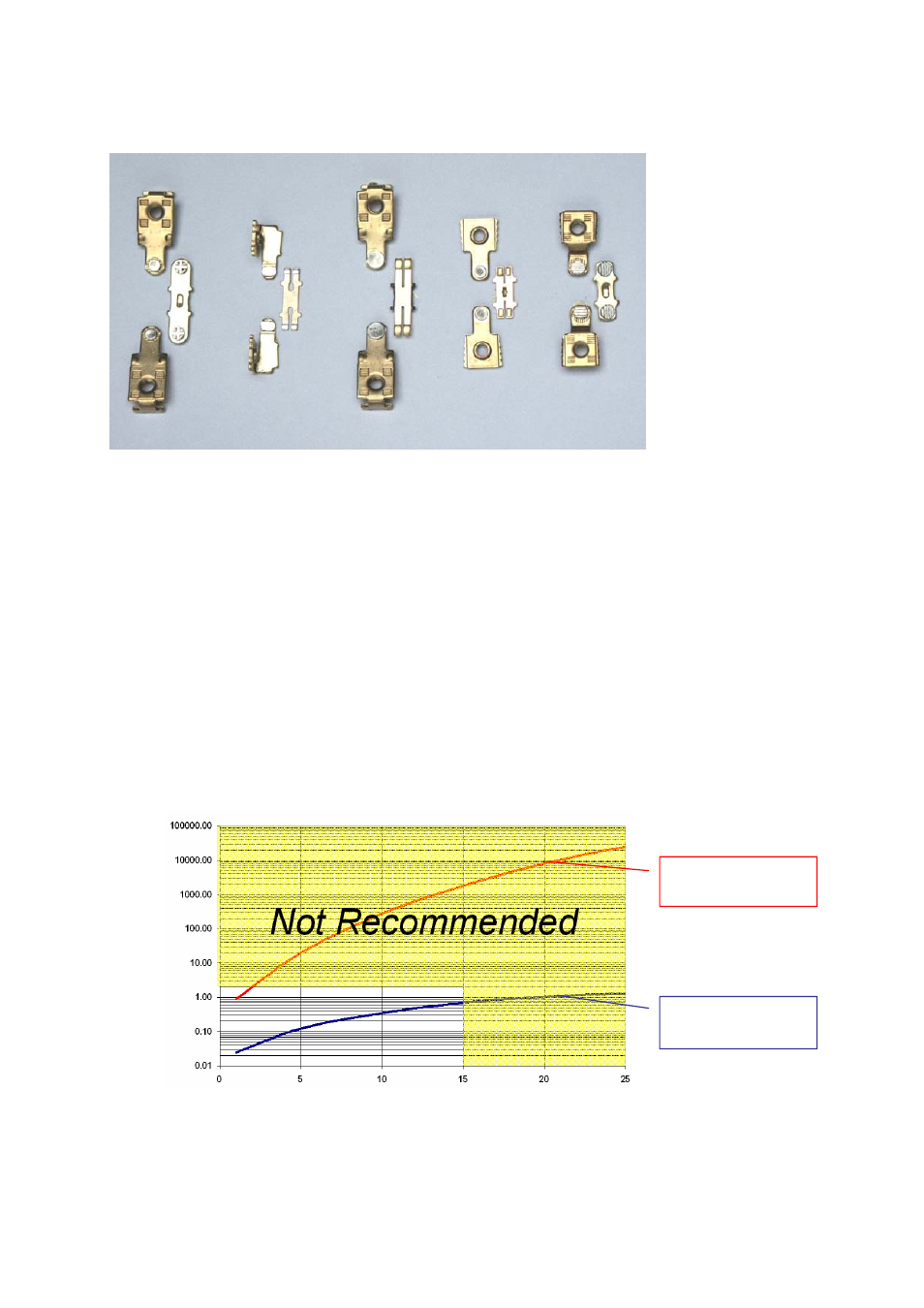

Fig. 5.3-10

Double contacts, increased contact pressure (for example by riffling of the contact surface) and gold-

plating are some of the possible approaches to obtain good contact reliability

The attainment of satisfactory contact and hence functional reliability requires appropriate

measures by the device manufacturer and the user. On the user side, the selection of a suitable

contact design for the respective application from the manufacturer’s product range, compliance

with manufacturer specifications and the measures listed above will have a beneficial effect on

contact reliability. Care is required with all kinds of chemical substances in the switching

cabinet. Thus while contact sprays may be good for oxidized sockets – for switching contacts

they are poison!

Universal control contacts can be used over a wide range of voltages and powers. They are

suitable both for switching contactor coils at 230 V or 110 V and for control of PLC’s at 24 V. To

achieve a high degree of contact reliability, contacts should normally not be connected in series

at the small control voltages as common with PLC control. With contacts that are specially

designed for low signal levels it should be noted that even single switching operations at higher

power levels can destroy the surface structures and hence the electronic-compatibility will

completely be lost or at least strongly reduced.

Universal

control contacts

Num

ber of fai

lure

s

per 1 million operations

Special low-level

control contacts

Number of contacts in series

Fig. 5.3-11

Typical contact reliability values at 15 V/5 mA of universal control contacts and special low-level control

contacts

LVSAM-WP001A-EN-P - April 2009

5-11