Rockwell Automation 1771-PM , D17716.5.18 U MNL 1771-PM CLUTCH/BRAKE MOD User Manual

Page 12

Clutch/Brake Controller Hardware

Chapter 3

3Ć3

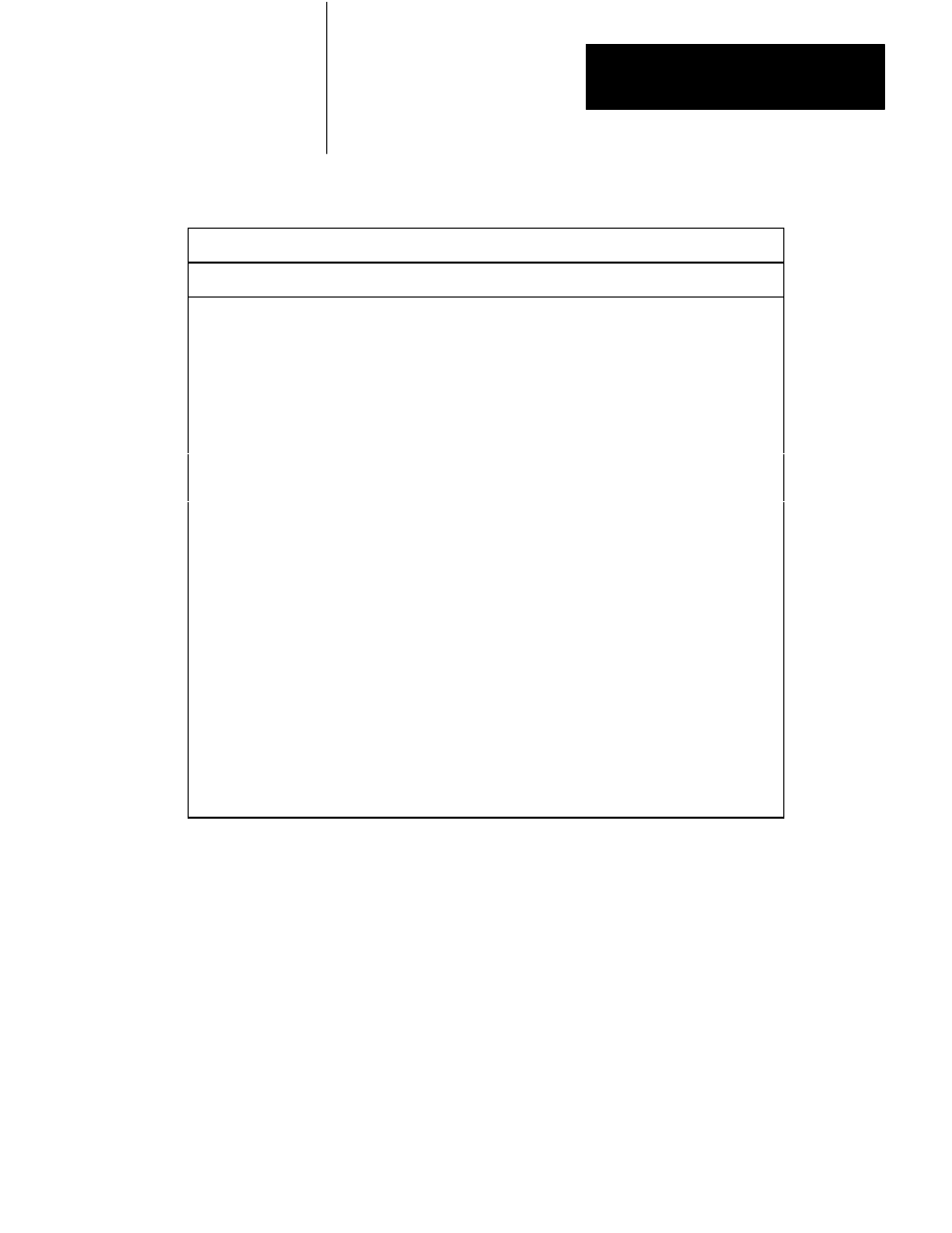

Table 3.A

Required and Optional Hardware

Quantity

Item

Cat. No.

Function

Important: (You must use 8Ćpoint modules with 2Ćslot addressing)

Required Hardware

2

Clutch/Brake Module

1771ĆPM

Monitors and controls the press

2

Wiring Arm

1771ĆWB

Connections to 1771ĆPM

2

I/O Chassis

1771ĆA2B Contains the modules

10

120V AC Input Modules

1771ĆIA

Monitors press inputs

2

120V AC Isolated Output Modules

(Series C)

1771ĆOD

Controls press outputs

Optional Hardware

2

120V AC Output Modules

1771ĆOA

Display of diagnostic messages

1

120AC Output Module

1771ĆOA

Controls optional indicators

2

120V AC Input Modules

1771ĆIA

Dump valve circuit

2

120V AC Isolated Output Modules

(Series C)

1771ĆOD

Dump valve and/or microĆinch circuit

2

I/O chassis

1771ĆA4B Substitute chassis when using the

optional dump valve circuit.

1

120V AC Output Module

1771ĆOA

MicroĆinch indicator

2

120V AC Input Modules

1771ĆIA

MicroĆinch circuit

2

120V AC Input Modules

1771ĆIA

Additional operator stations

Clutch/brake modules operate in parallel to monitor and control your

press. Clutch/brake modules are also called “voting processors” because

they must always have a consensus. Unless both voting processors

constantly agree that they sense identical conditions in your clutch/brake

press system, either or both voting processors stop press motion or

prevent it from starting.

Your clutch/brake controller monitors and controls your press. Although

your PLC does not control your press, it does configure and enable the

clutch/brake controller. Your PLC ladder program can monitor inputs to,

and the status of, your clutch/brake controller. This allows your PLC to

control other indicators, machines, or processes related to your press

system.