Rockwell Automation 1746-NR8 SLC 500 RTD/Resistance Input Module User Manual User Manual

Page 79

Publication 1746-UM003A-EN-P

Ladder Programming Examples 5-7

Using the Proportional

Counts Data Format

with the User-set Scaling

(Class 3)

The RTD module can be set up to return data to the user program that is

specific to the application. Assume that the user controls the line speed of a

conveyor using a 1000

Ω

potentiometer connected to channel 0 of the RTD

module. The line speed will vary between 3 feet/minute when the

potentiometer is at 0

Ω

and 50 feet/minute when the potentiometer is at

1000

Ω

.

Example - Configure the RTD module in Class 3 operation to return a value

between 3 and 50 in the data word for channel 0. Proceed as follows:

1.

1.

1.

1. Set bits 0 through 3 of configuration word 0 to 1110 to select the

1000

Ω

potentiometer input type.

2.

2.

2.

2. Set bits 4 and 5 of configuration word 0 to 11 to select proportional counts

data format.

3.

3.

3.

3. Enter 3 as the low range into N10:8.

4.

4.

4.

4. Enter 50 as the high range into N10:9.

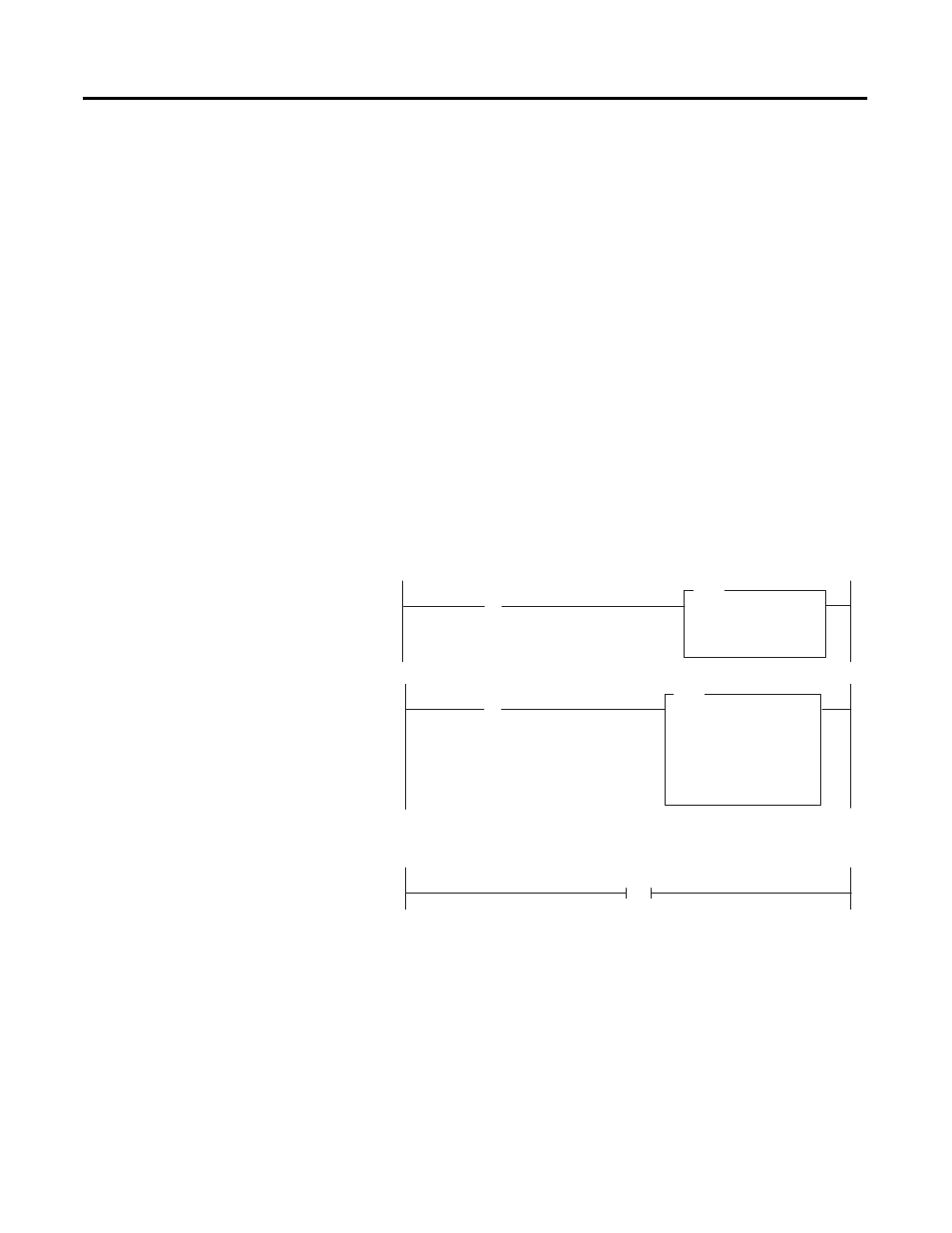

Figure 5.7 Programming for PID Applications)

For Class 3 operation registers N10:8 and N10:9 can be used to scale channel 0

for a minimum conveyor speed of 3 ft./minute and a maximum conveyor

speed of 50 ft./minute

] [

COP

COPY FILE

Source

#N10:0

Dest

#O:3.0

Length

10

S:1

15

SCL

SCALE

Source

I:3.0

Rate [/10000]

Offset

Dest

] [

I:3.8

11

END

First Pass Bit

Initialize RTD module.

Rung 2:0

Rung 2:1

Ten elements are copied from the specified source

address (N10:0) to the specified output (O:3.0). Each

element is a 16-bit integer as shown in the data table

at the bottom of the page.

The

Source of this instruction is the data word from the

RTD module, which is a number between 3 and 50. The

Dest in this application is an analog output channel

controlling the speed of the conveyor motor drive. The

Rate and Offset parameters should be set per your

application. Refer to the S

LC 500 and MicroLogix 1000

Instruction Set Reference Manual (publication

1747-6.15) or the

Analog I/O User Manual (publication

1746-6.4) for specific examples of the SLC instruction.

Rung 2:2