Typical applications input capabilities, Turbine shaft speed monitoring, Automotive paint booths – Rockwell Automation 1794-ID2 U.MNL INCREMENTAL ENCODER User Manual

Page 15: Brewery flow monitoring, A+ and a, B+ and b, Z+ and z

1–3

Overview of the Incremental Encoder Module

Publication 1794ĆUM015B-EN-P - May 2001

ADAPTER

ACTIVE

FAULT

LOCAL

FAULT

24VDC

POWER SUPPLY

RIO ADAPTER

1794ĆASB

AllenĆBradley

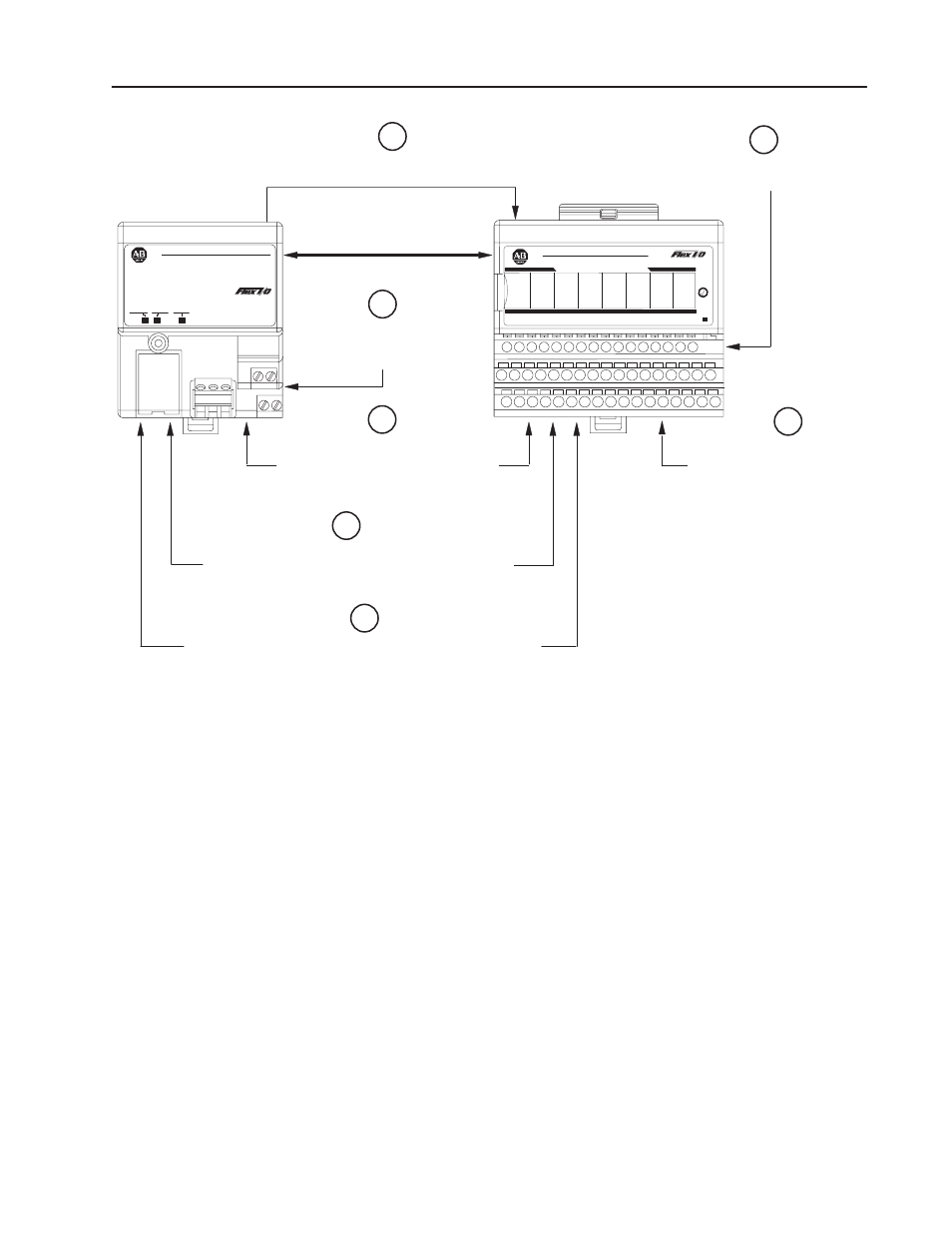

1

The adapter transfers your configuration data

to the module using a BTW.

Flexbus

External devices transmit

frequency signals to the module.

2

The module converts

frequency signals into integer

format and stores these values

until the adapter requests their

transfer.

3

Your ladder program instructs the

adapter to perform a BTR of the values

and stores them in a data table.

4

The adapter and module determine

that the transfer was made without error

and input values are within specified

range.

5

Your ladder program can use and/or move the data (if valid)

before it is written over by the transfer of new data in a

subsequent transfer.

6

Your ladder program performs BTWs to the module when you power

it up, and any time you wish to reconfigure the module.

7

OK

2 CH INCREMENTAL ENCODER

1

1794-ID2

AllenĆBradley

You can use the 1794–ID2 module in the power management,

automotive, food and beverage, and oil and gas industries for various

flow and/or turbine metering applications. Some sample

applications include:

•

turbine shaft speed monitoring

•

automotive paint booths

•

brewery flow monitoring

•

petrochemical flow and custody transfer

The incremental encoder module has 2 identical input channels.

Each of the input channels may accept these input signals:

•

A+ and A–

•

B+ and B–

•

Z+ and Z–

•

G+ and G–

The pulse inputs can accept frequencies up to 100KHz. The module

accepts and returns binary data.

Typical Applications

Input Capabilities