Specifications, Appendix a, Appendix a lists the modul – Rockwell Automation 1756-HYD02 ControlLogix Hydraulic Servo Module User Manual

Page 83: Appendix

Publication 1756-UM525A-EN-P - June 2003

83

Appendix

A

Specifications

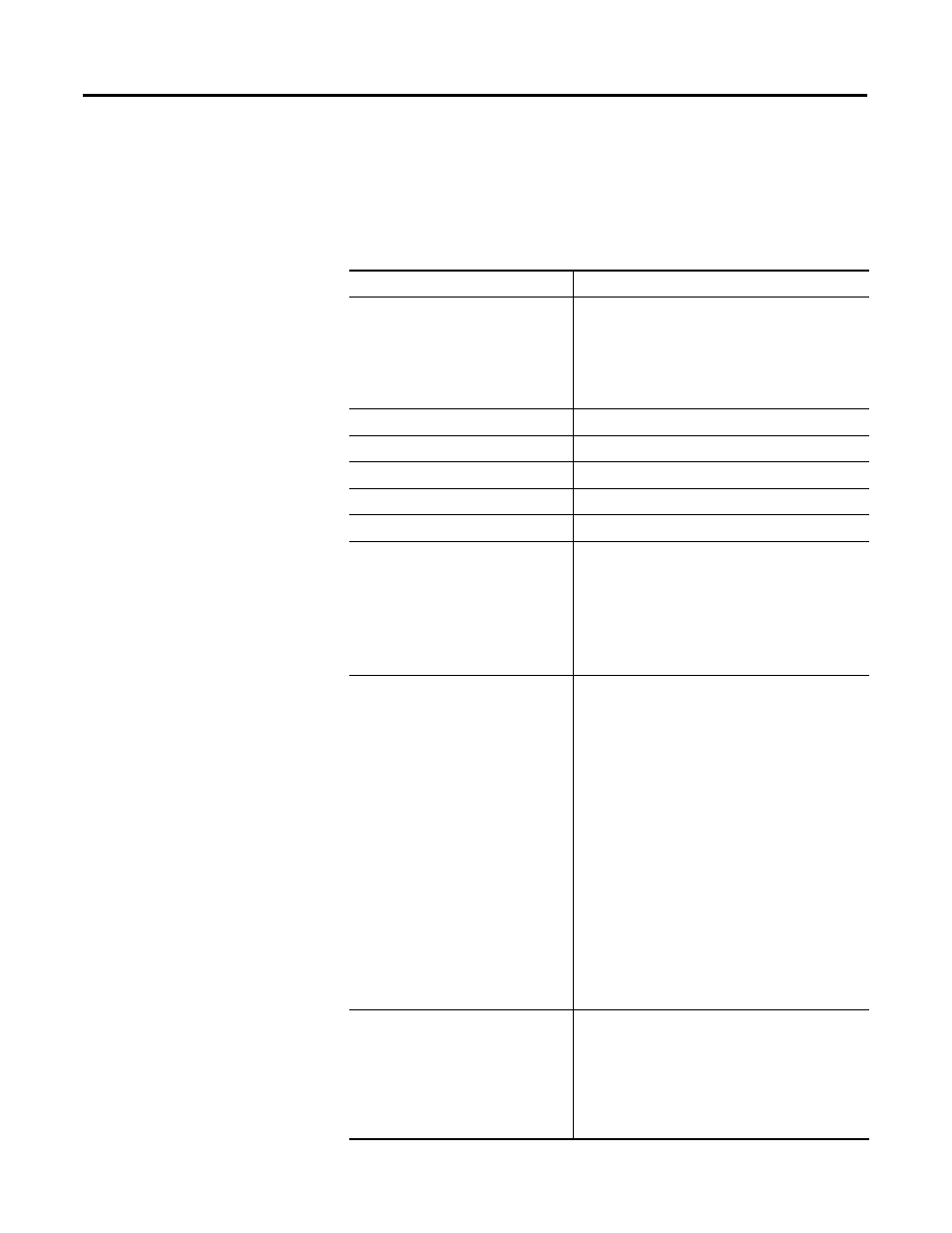

Number of axes

2 axes maximum

Servo loop

Type

Gain resolution

Absolute position range

Rate

Proportional, integral and differential (PID) with

Feed-Forwards and Directional scaling

32- bit floating point

230,000 LDT counts

500Hz to 4kHz (Selectable)

Module location

1756 ControlLogix chassis

Module keying

Electronic

Power dissipation

5.5W maximum

Thermal dissipation

18.77 BTU/hr.

Backplane current

5.1V dc @ 700mA and 24V dc @ 2.5mA

LDT input

Type

Sample rate

Resolution

(1)

Electrical interface

Input impedance

Output load

PWM, Start/Stop rising or falling edge

120MHz (8.33ns)

Less than 0.001 inch with single recirculation

Isolated 5V differential (RS-422 signal)

215 Ohm differential

100 Ohm minimum

Registration inputs

Type

24V dc input voltage

Maximum on

Minimum on

Maximum off

5V dc input voltage

Maximum on

Minimum on

Maximum off

Input impedance

24V dc input

5V dc input

Response time (position latched)

Optically isolated, current sinking input

+24V dc nominal

26. 4V dc

18. 5V dc

3.5V dc

+5V dc nominal

5.5V dc

3.7V dc

1.5V dc

1.2 k

Ω

9.5 k

Ω

1 servo update period - Servo update period is the

period at which the position and/or velocity

feedback is sampled and a new servo loop is

closed to generate a new servo output. The time of

this period is a user-defined setting from 250

μ

s to

2000

μ

s.

All other inputs

Type

Input voltage

Maximum on

Minimum on

Maximum off

Input impedance

Optically isolated, current sinking input

+24V dc nominal

26. 4V dc

17. 0V dc

8.5V dc

7.5 k

Ω