What this chapter contains, Using general module features, Servo update period – Rockwell Automation 1756-HYD02 ControlLogix Hydraulic Servo Module User Manual

Page 42

42

Publication 1756-UM525A-EN-P - June 2003

Chapter 4 Using the 1756-HYD02 Module Features

What This Chapter Contains

This chapter is broken into the two sections.

Using General

Module Features

The general module features include:

• Servo Update Period

• Module Fault Reporting

• Fully Software Configurable

• Electronic Keying

Servo Update Period

Servo update period is the period at which the position feedback is sampled

and the loop is closed to generate a new output value. The time of this period

is a user-defined setting. You can choose from one of the following settings:

• 250

μ

s

• 500

μ

s

• 1000

μ

s

• 1500

μ

s

• 2000

μ

s

With LDTs, the minimum Servo Update Period is dependent on the length of

the transducer. Use the Calculated Values tool on the Feedback tab of the Axis

properties dialog in RSLogix 5000, in conjunction with the response of your

hydraulic application, to calculate suggested minimum update periods. The

coarse update period of the associated motion group must be at least 3x the

maximum configured 1756-HYD02 module servo update period or

RSLogix 5000 will generate an error.

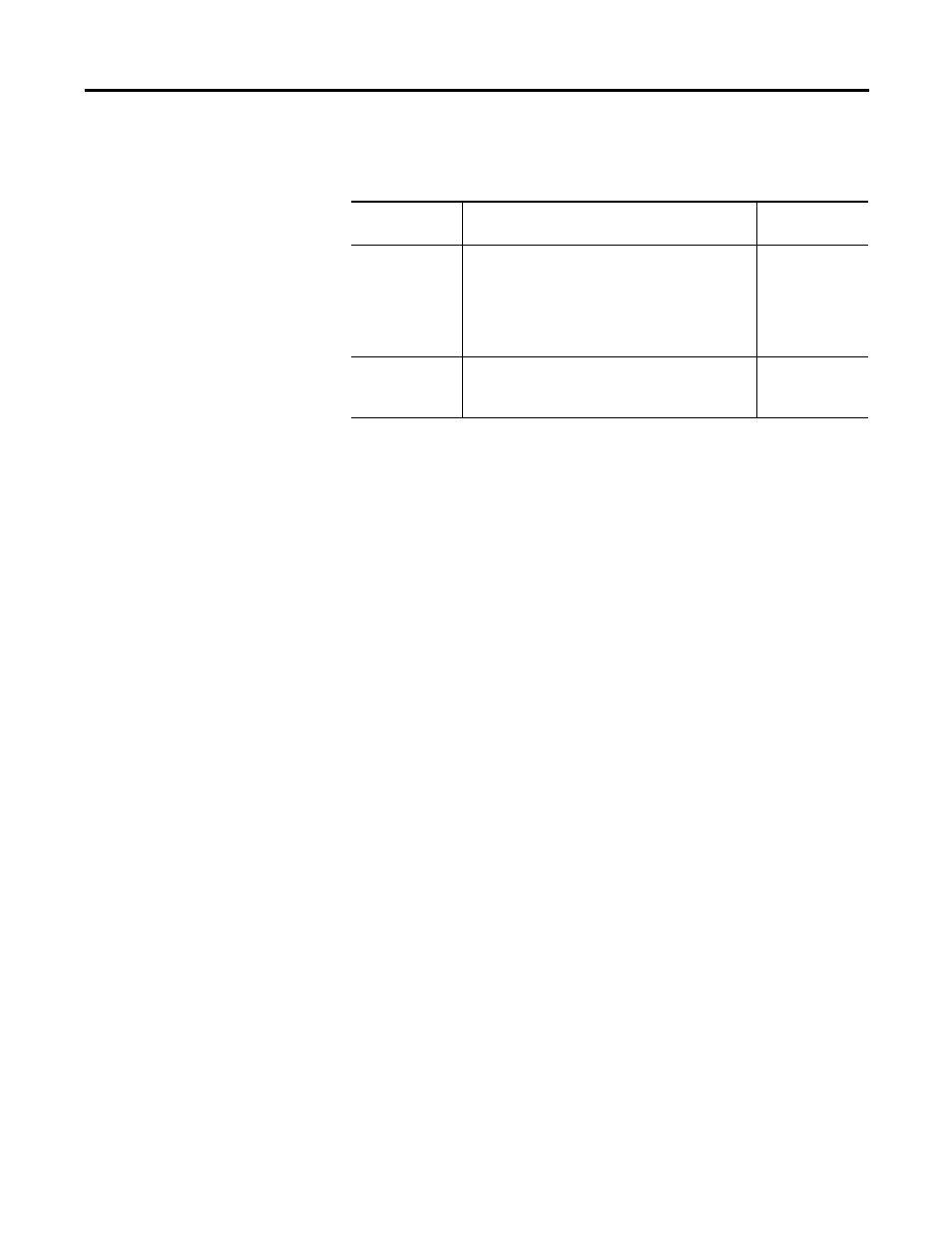

Section:

Description:

Begins on

page:

This section describes features that affect the

module in a general sense. For example, the

1756-HYD02 module offers electronic keying

options that you can configure to set the degree of

protection your application needs against using

the wrong 1756-HYD02 module.

This section describes features that are specific to

the axes connected to channels 0 and 1 on the

1756-HYD02 module.