Conversion tab – Rockwell Automation 1756-HYD02 ControlLogix Hydraulic Servo Module User Manual

Page 59

Publication 1756-UM525A-EN-P - June 2003

59

Using the 1756-HYD02 Module Features Chapter 4

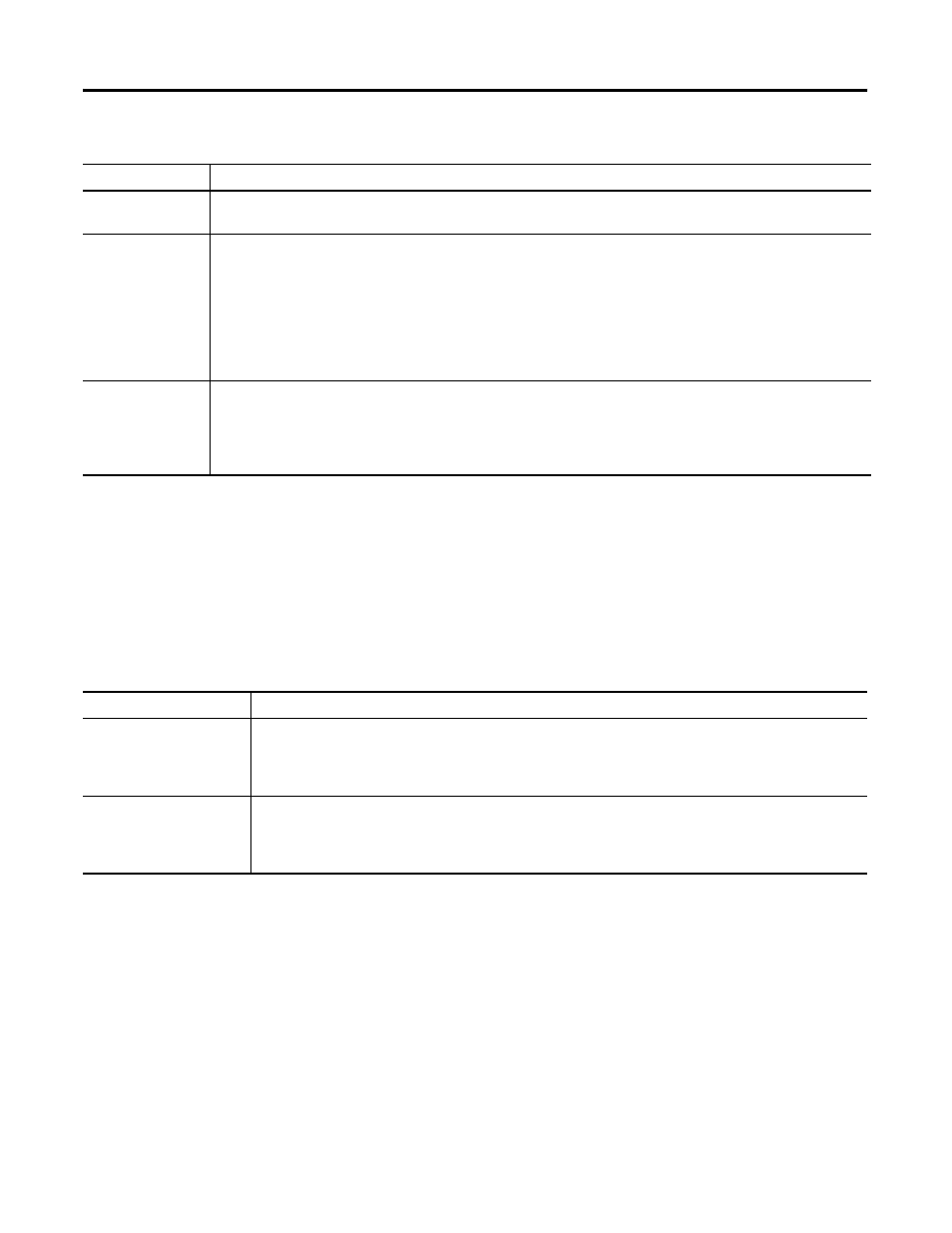

Conversion Tab

Use this tab to view the Positioning Mode and configure the Feedback

Resolution for an axis. The table below lists the configurable features available

on the Conversion tab.

Absolute Feedback

Offset

The absolute offset is used to place the machine zero point at the desired location relative to the zero point of the

LDT. The LDT zero point is inside the transducer head and physically unattainable.

Calculated

Values:Conversion

Constant

Calculation derived from values based on the configuration values entered for the LDT.

The calculated conversion "K" constant is derived based on the LDT configuration values entered on the Feedback

tab. After proper LDT values are entered and the Calculate button is selected, the resultant "K" value is calculated.

This "K" value must be taken from this tab and entered in as the Conversion constant on the Conversion tab.

You must type the new conversion constant in the Conversion Constant field on the Conversion tab. RSLogix 5000

does not automatically update the field after you use the Calculate button on this tab.

Calculated

Values:Minimum

Servo Update Period

Calculation derived from values based on the configuration values entered for the LDT.

You can use the calculate button located on the Feedback tab to calculate the appropriate K constant value. The

calculated K constant is derived based on the LDT configuration values entered on the Feedback tab, and must be

taken from that tab and used here.

Feature:

Definition:

Feature:

Definition:

Positioning Mode

The Linear positioning mode is the only positioning mode available on the 1756-HYD02 module. This mode

provides a maximum total linear travel of 230,000 feedback counts. With this mode, the unwind feature is

disabled and you can specify the positive and negative travel limits for the axis to limit the linear travel

distance traveled by the axis.

Conversion Constant

Type the number of feedback counts per position unit. This conversion – or “K” – constant allows axis

position to be displayed, and motion to be programmed, in the position units set in the Units tab. The

conversion constant is used to convert axis position units into feedback counts and vice versa. You can

calculate this value on the Feedback tab.