Servo tab – Rockwell Automation 1756-HYD02 ControlLogix Hydraulic Servo Module User Manual

Page 57

Publication 1756-UM525A-EN-P - June 2003

57

Using the 1756-HYD02 Module Features Chapter 4

Servo Tab

For an axis of the data type AXIS_SERVO, configured for Servo operation

(i.e. closed loop operation) in the General tab of this dialog box, use the

SERVO tab to:

• configure an external drive.

• configure the drive fault input.

• select up to two axis attributes whose status can be monitored.

The table below lists the configurable features available on the Servo tab.

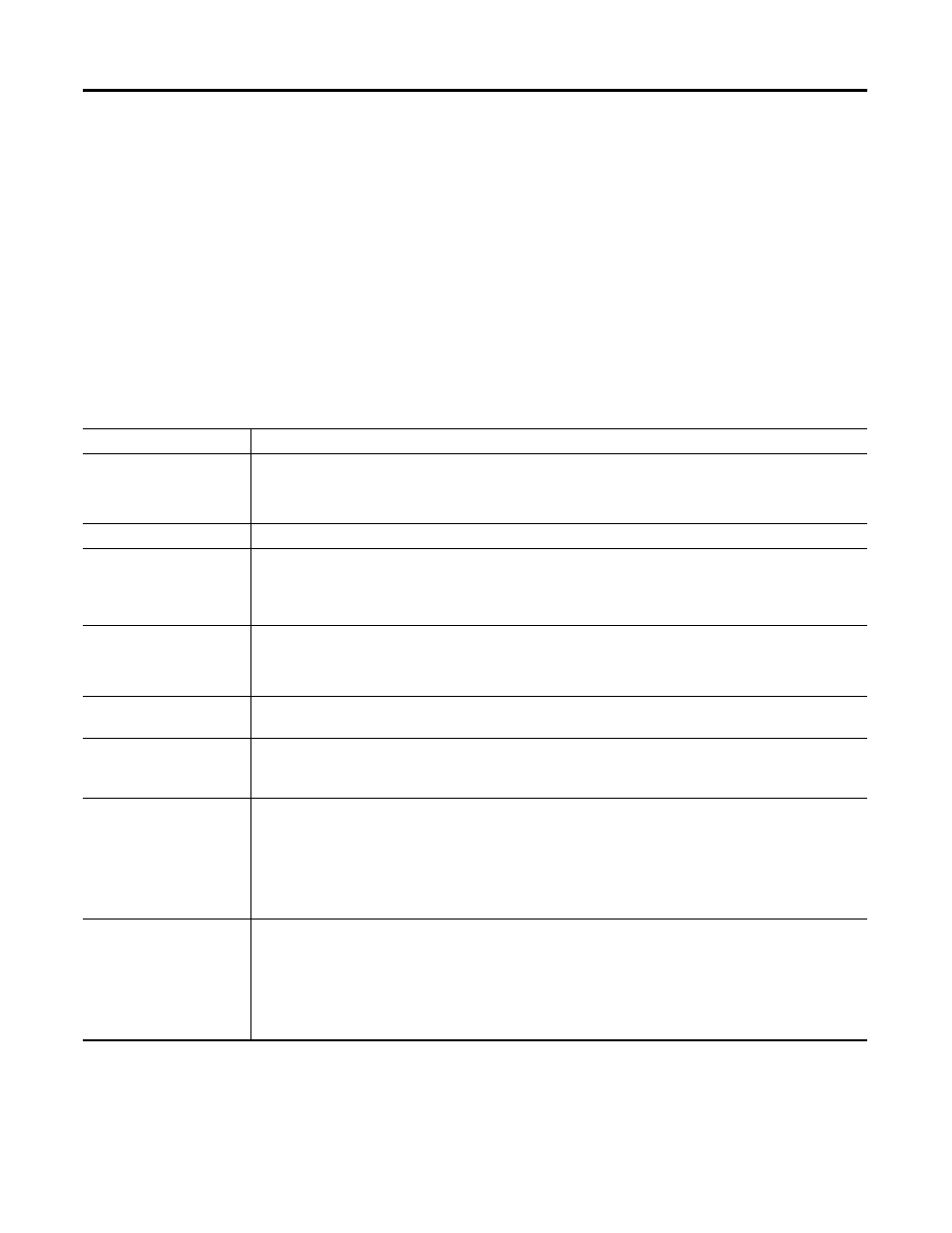

Feature:

Definition:

External Drive

Configuration

Select the Hydraulic drive type. This drive type selection enables proportional, integral and differential (PID)

position loop gains with Feed-Forwards and Directional scaling for the axis loop.

The Torque and Velocity options are not valid on the 1756-HYD02 module.

Loop Configuration

Currently, only Position Servo is available.

Enable Drive Fault Input

When selected, this feature enables the drive fault input. When the drive fault is detected, appropriate

action is taken based on the Drive Fault Action specified in the Fault Actions tab of this dialog box. On

hydraulic systems, you can use this input if the valve or hydraulic power unit has an output indicating a fault

condition.

Drive Fault Input - Normally

Open or Closed

Specifies the usual state of the drive fault output:

• Normally Open - sources current when a fault is present

• Normally Closed - sources current when a fault is not present

Enable Direct Drive Ramp

Control

Check this box to enable direct drive ramp rate control.

Direct Drive Ramp Rate

This attribute specifies the rate at which the analog output changes from the current value to the requested

value when a Motion Direct Drive On (MDO) command is given. The ramp rate is specified in V/s. The value

should be selected to allow the axis to change speed rapidly without causing excessive shock.

Real Time Axis Information

- Attribute 1

The first axis attributes whose status is transmitted – along with the actual position data – to the Logix

processor. Once the attribute is selected, the real time axis information is automatically updated in the axis

tag structure, as long as Auto Tag Update is enabled.

If a GSV is done to one of these loop status attributes without having selected this attribute via the Real

Time Axis Information attribute, the attribute value will be static and will not reflect the true value in the

hydraulic module.

Real Time Axis Information

- Attribute 2

The second axis attributes whose status is transmitted – along with the actual position data – to the Logix

processor. Once the attribute is selected, the real time axis information is automatically updated in the axis

tag structure, as long as Auto Tag Update is enabled.

If a GSV is done to one of these loop status attributes without having selected this attribute via the Real

Time Axis Information attribute, the attribute value will be static and will not reflect the true value in the

hydraulic module.